Paul Studebaker is chief editor of Sustainable Plant. He earned a master's degree in metallurgical engineering and gathered 12 years experience in manufacturing before becoming an award-winning writer and editor for publications including Control and Plant Services.

Global energy supplies and demands are undergoing an unprecedented transformation as yesterday's fears of energy scarcity are replaced with a new era of energy abundance due to innovative practices in the oil and natural gas industry. Instrumentation and control engineers are matching those process innovations with their own refinements of methods for engineering, installing and commissioning systems.

And Rockwell Automation is keeping pace with acquisitions, products and services to support this area of exploding growth, company representatives relayed to assembled media and analysts at today's Automation Perspective event in the lead up to Automation Fair this week in Houston.

SEE ALSO: Plants Find Powerful Ways to Boost Energy Efficiency

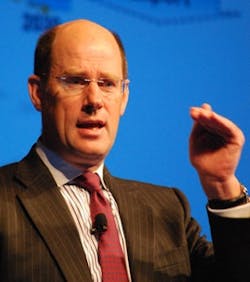

"It's very much a hydrocarbon world, and it will be for a long time to come," said David Pruner, senior vice president and head of North American gas and power account management, Wood Mackenzie Ltd. "In 2019, coal will surpass oil as the world's primary source of energy."

By 2030, China and India's energy consumption will more than double compared to 2013. "It's all about electricity output, and in China and India, that's basically all coal because it's the cheapest and most plentiful source," Pruner said. The rest of the world is primarily choosing natural gas to produce electricity. In addition to power production, China and India have rapidly increasing demand for coal in industry, primarily iron and steelmaking, and cement production.

In the United States, the energy revolution is due to hydraulic fracturing for natural gas. Starting with the Marcellus and Utica shale formations and progressing through a dozen others, shale gas deposits in the U.S. are mapped, characterized, costed, and queued up to be put into production as demand and prices rise.

"It's very much a hydrocarbon world, and it will be for a long time to come." Wood Mackenzie's David Pruner on the world's continued reliance on fossil fuels, including the resurgence of coal as global number one source of energy.

Outputs from Marcellus and Utica wells are on track to double between 2012 and 2016, largely due to improving hydraulic fracturing techniques that are producing from formerly tapped-out fields. U.S. energy from coal is declining, and from gas it's increasing, due to the low cost of gas and the relatively high cost of bringing coal-fired plants into compliance with mercury and air toxics emissions limits.

"It's a paradigm shift in U.S. production," Pruner said. Abundant natural gas supplies are driving an industrial renaissance in chemical plants and natural gas-based industries such as plastics and certain pharmaceuticals.

The United States is on track to become a significant global supplier of liquefied natural gas (LNG). On the world market, U.S. LNG suppliers have a cost advantage because U.S. gas is produced on brownfield sites where exploration and characterization are already done. Wood Mackenzie projects that natural gas prices will stay around $4/MMbtu through about 2016, then rise slowly to $6 - $8 by 2025.

Pruner expects the United States to achieve energy independence by 2028 "on a net basis," he said. "We'll continue to import oil."

One Energy Company's Response

Controls engineers are scrambling to keep pace with energy production projects, which "involve a high level of activities simultaneously in multiple locations around the globe, with ever shorter project lifecycles," said Sandy Vasser, facilities electrical and instrumentation manager, ExxonMobil Development Company. "Successful project execution for automation systems is extremely difficult, but can be achieved."

Vasser's strategy is simple: identify all of a project's I&C-related activities early, plan a flawless execution, contract with the very best resources, and assign each piece to the best resource for that piece. Then select the best and proven technology, guided by an I&C "toolkit of go-bys, guides and tools." Identify and manage all dependencies and interfaces. Finally, identify cost efficiencies and take advantage of them, remove barriers, and learn and improve from the results.

He cites three major remaining problem: projects are requiring more I/O, changes cause delays, and changes after field acceptance test (FAT) lead to significant rework as well as delays. So ExxonMobil has challenged its suppliers to help them eliminate and automate steps; simplify and streamline the steps that remain; eliminate components, dependencies and interfaces; accommodate change; and simplify and automate documentation.

"We used to improve by perfecting and supplementing conventional methods, but if all we do is improve the way we've always done it, all we'll get are incremental improvements," Vasser said. "We need to rethink the way we go about things."

For example, the conventional control, marshalling and I/O cabinets are each highly engineered for a specific project. The project must wait for these to be engineered and constructed. Instead, he uses standard I/O cabinets — junction boxes — in the field, ordered based on the approximate I/O count with room to spare. "These can be installed before the controls are engineered," Vasser said. Controls are also ordered in a standard configuration. Marshalling cabinets are eliminated by using networks.

During construction, field devices can be connected to the nearest junction box, "It doesn't matter which one," Vasser said.

Meanwhile, the control software can be tested via simulation and visualization – "FAT without hardware," Vasser said. In the future, he expects that on installation, the control system will auto-detect the field devices, then configure, enable and document them and the I/O.

"We have to challenge the existing traditional practices and technologies, and look for opportunities to make leaps in improvements," Vasser concluded. "We want to take automation off the critical path."

Rockwell Automation Expanding Oil & Gas Capability

Rockwell Automation has steadily increased its footprint in oil and gas through acquisition and product development, said Blake Moret, senior vice president, control products and solutions, Rockwell Automation, "from downstream up, product by product and customer by customer."

The company integrates control, logic and safety for specific applications by selecting the best products, then knitting them together. "Our most recent acquisition, vMonitor, helps us to achieve the digital oilfield through remote monitoring, secure wireless and packaged implementations."

Remote services are not new. "We've had it for years," said Moret, but now it's on a smaller, less costly footprint. "It's about connectivity back to the expert, so customers can overcome the skills gap," as well as keep on-site personnel away from dangerous equipment.

The same control system performing automation also can feed information to an energy management system, in context of process and production data. This is helping one Tyson Foods plant save 10% on energy — a 1-year payback — and it's being rolled out in its other facilities.

Sponsored Recommendations

Leaders relevant to this article: