Dan Hebert is a contributing editor for Control and Control Design.

3D printing started off as a novelty with very few industrial applications, but this is changing rapidly as the printers get better and faster. As the technology improves, more and more custom and complex parts are being made using 3D printing, as opposed to conventional methods because it’s cheaper and faster and produces higher-quality components.

3D printing is often called additive manufacturing, which indicates the key difference from traditional methods of producing parts which are subtractive processes. Whether done by hand, a CNC machine or some combination of both, subtractive processes form parts by removing or subtracting material from bar or other stock, whereas 3D printing produces parts by adding material in layers.

Industrial and commercial customers are turning to 3D printing for two main reasons. The first is lower cost in applications where a 3D printer can make a relatively simple part for less than creating it by hand or with traditional CNC machining. The second is to produce very complex custom parts automatically, often with exotic materials, which are virtually impossible to make solely with subtractive machines. In the past, many of these parts required a high degree of manual labor during the production process.

Here’s how 3D printing can save money as compared to subtractive manufacturing. “The Rocky Mountain Dinosaur Resource Center used to make replica bones through the use of contract five-axis CNC routers which run upwards of $150/hr for machine time, or about $1,200 per bone,” says Clay Guillory, CEO of Titan Robotics. “They purchased one of our machines and now 3D print bones for less than $150 in material and one hour of in-house, low-skill labor. Even with a print time of a few days, our machine saves a lot of money for this customer.”

As seen in this example, making parts with 3D printers is very slow compared to subtractive manufacturing processes, but much lower in cost in many instances. This makes them a great fit for custom parts produced in relatively low volumes.

And, although it may take a long time to make a part, it’s not a process requiring constant interaction by an operator. “Part production can run for weeks on end with zero supervision, unlike most traditional machine tools. Reduction in labor and material waste thus creates a more efficient and economical solution for many industries,” explains Guillory.

Also read: Industrial Partners Plunge Into 3D Printing

The second main reason to use 3D printing is for making very complex parts, often with exotic materials, in an automated manner instead of by hand. “Titan has the capability to create any machine configuration or type of extrusion system for customers using materials such as thermoplastic, foam, paste, ceramic and concrete,” notes Guillory (Figure 1).

Markforged makes 3D printers to produce a type of plastic part that’s much less expensive than its metal equivalent. “Our 3D printer, the Mark Two, is an industrial-strength printer that empowers any engineer to print parts as strong as aluminum,” claims Rebecca Dilthey, senior product marketing manager.

Figure 1: This Titan Robotics 3D printer is used by an industrial design facility in Brooklyn, New York, which uses it to make large modern art designs, as well as end-use displays for commercial and retail customers.

Source: Titan Robotics

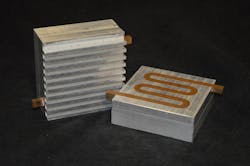

Figure 2: Fabrisonic’s machines use a metal 3D printing technology, employing sound which merges layers of thin metal foil stock to produce parts such as this one.

Source: Fabrisonic

“Mark Two parts are nylon-based and reinforced with continuous strand carbon fiber, fiberglass or Kevlar. Instead of having to pay for a metal 3D printer or waiting for a service bureau to send a part, engineers can have the strength of metal with the flexibility of 3D printing,” explains Dilthey.

Mark Two customers are printing a wide range of parts from functional prototyping, tooling and fixtures to custom end-use parts. The common thread throughout these applications is the need for a strong part. “The cost of machining parts in aluminum is extremely high, especially if the part is low-volume. In addition, in the time it would take to get the first iteration of a part back from the machine shop, an engineer could have the finalized design printed on a Mark Two,” concludes Dilthey.

Another company uses 3D printing to produce parts with extremely complex geometries. “Our machines use ultrasonic additive manufacturing (UAM), which is a metal 3D printing technology employing sound to merge layers of thin metal foil stock,” explains Mark Norfolk, PE, president and CEO of Fabrisonic.

UAM produces true metallurgical bonds with full density and works with a variety of metals such as aluminum, copper, stainless steel and titanium. In combining additive and subtractive process capabilities, UAM can create deep slots; hollow, latticed or honeycombed internal structures; and other complex geometries impossible with conventional subtractive manufacturing processes.

“The ability to build fully dense metal parts in a variety of relevant engineering materials is at the core of UAM’s value proposition. From this core capability, three unique opportunities arise: create complex 3D internal channels, which is an enabler for molds, thermal management and chemical processing; embed one material in another, which is an enabler for metal matrix composites, integrated sensors, and smart systems; and join dissimilar materials, which is an enabler for cladding and transition joints (Figure 2),” points out Norfolk.

3D printing can be used to create complex parts from exotic materials via an additive manufacturing process, which is unfamiliar to many machine builders; they’re generally more acquainted with traditional subtractive machining. But, while the manufacturing process is different, many of the automation components used in 3D printers are similar to those used in more traditional machines.

Exotic parts, standard automation

Like subtractive machines, 3D printers need HMIs, controllers and motors. “Our 3D printer control system uses an onboard screen/encoder with direct connection to a Smoothieboard open-source CNC controller. The HMI, a 4.25-in monochromatic screen with a simple push-button encoder, controls all interaction with the machine,” relates Titan’s Guillory.

“This simple combination creates a bulletproof controller for long print runs. The output signals from the Smoothieboard controller are converted to servo signals within Yaskawa servo cards. The 2 million line encoders on the Yaskawa servo drives are unparalleled in the 3D printing industry, and closed-loop feedback creates a much smoother and more reliable print versus traditional stepper drives. The direct-drive lead screw configuration on all axes provides a backlash free print. Omron solid-state relays coupled with PID controllers maintain temperature within the enclosure,” adds Guillory.

Fabrisonic machines also use automation components familiar to many in the CNC arena. “Standard G-code driven automation is used to control our machines,” explains Fabrisonic’s Norfolk. “We use a Siemens 840D to drive a suite of Siemens servo drives and pneumatics, and the HMI is a Siemens Sinumerik. The ultrasonic components are homebuilt 20 kHz, 10 kW sonic drives.”

The use of standard automation components in 3D printers creates two opportunities. The first is for automation suppliers looking to this area for growth as more parts migrate from manual production to automated additive manufacturing. The second opportunity is for machine automation professionals, many of whom will find their skills easily transferable from subtractive to additive manufacturing.