The Control System Integrators Association (CSIA) announced its board of directors at the CSIA Town Hall Business Meeting in May. The new CSIA Board of Directors is:

- Adrian Fahey, board chair, managing director and CEO, Sage Automation (2021-2023)

- Ray Brown, director, ESCO Group

- Karen Griffin, director, Hargrove Controls + Automation

- Stephen Malyszko, director, Malisko Engineering

- Frank Riordan, director, DMC

- Greg Young, director, Automation NTH

- Daren Dieleman, director of operations, Interstates

- Luigi de Bernardini, past chair, Autoware.

The new board of directors was affirmed by a quorum of the CSIA membership during the virtual Town Hall Business Meeting. Fahey stated: “I’m thrilled to be affirmed by the membership of CSIA as the new board chair. It is an exciting time to be leading this organization as we begin to move toward a hopeful transition out of the global pandemic. I look forward to meeting in person again soon with our members at the 2022 CSIA Executive Conference in Denver.”

CSIA CEO Jose Rivera added: “Adrian Fahey follows Luigi de Bernardini as chair of the board. Both are CEOs of international system integrators, underscoring the association’s growing international presence. CSIA has members in 35 different countries, and certified members are headquartered on every continent except Antarctica.”

What are three key things that a machine builder, system integrator or manufacturer should know about your organization?

Luigi de Bernardini, CEO, Autoware: Autoware has developed smart-manufacturing solutions since 2001. We have 20-plus years in digitizing production processes in various industry verticals but mostly in FMCG.

Our motto is "tailored based on standard." We believe in the importance of using standard platforms to develop our solutions, but, at the same time, we are fully aware that they need to be tailored to the specific client's needs. Each company is different in terms of organization, culture and assets. Any solution needs to empower the strengths and solve the weaknesses, which are different company by company, even if they produce the same thing.

Autoware works mostly with big multinational and multisite companies all around the world. We have a long experience in rolling out solutions from remote, so we can serve our clients wherever they are. We even provide priority support services up to 24x7.

What new technologies are driving product development and why?

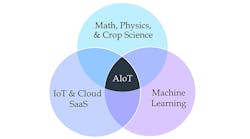

Luigi de Bernardini, CEO, Autoware: We are looking mostly at machine learning and analytics. In my opinion, they are the two that create value to our customers and the ones that we need to focus on.

How does the Industrial Internet of Things figure into business strategy?

Luigi de Bernardini, CEO, Autoware: IIoT is one of our technological pillars. We recognized the trend in 2014 and partnered with a leading vendor to implement IIoT solutions based on its platform. IIoT has unique characteristics that allow overcoming some of the limits of traditional platforms. Reduced footprint, possibility to easily implement solutions in brownfield environments and connect legacy production lines or assets, allow to extend digitization to plants that could not afford traditional solutions. We are only seeing the tip of the iceberg; much more will come. One important enabler will be 5G, allowing to connect any type of machine or device without big investments of infrastructure and reducing the network complexity. This is the reason why we are investing in it and growing our competencies in all the related aspects of it.

How will machine automation and controls alter the way companies staff their operations in the future?

Luigi de Bernardini, CEO, Autoware: That's a very interesting point. I don't know if the question is how machine automation and control will alter the staffing policies or how the new generation staff will require to alter the machine automation and controls. It's probably a mix of the two. We are seeing two distinct forces at the same time. New technologies allow adding more intelligence to machines. AI overall promises big changes in how machines will be managed. The increase of technology will require operators with different skills and capabilities. It will not be just technical skills, but even soft skills to manage a different interaction with the machines. On the other side, younger people are used to different technologies and have great expectations to use them in controlling machines and lines in an industrial environment in the same way they use them in their personal life. This is driving the demand for different ways to interact with machines. Moreover, the trend to stay in the same working position for a shorter time is driving the necessity to capture the user knowledge in some kind of repository to keep it part of the company knowledge that survives to the single operator.

How is the development of software solutions impacting requirements for hardware?

Luigi de Bernardini, CEO, Autoware: Even in this case, it's a mix of different trends. The increased possibility to implement cloud-based solutions changes the way software is developed and the requirements for hardware. We are seeing an increased demand for computational power at the cloud level to support software with continuously growing complexity. At the same time, we are seeing an increased demand for edge computational capabilities, smaller devices with enough power to provide local data transformation. In parallel, we are seeing an increased demand for mobile—not so much wearable at the moment—to deliver information to the users wherever they are.

Also read: Mazak debuts new technologies for CNC control, remote connectivity

As engineering and IT continue their convergence, which one is and/or will be leading the direction of future automation and technology?

Luigi de Bernardini, CEO, Autoware: I believe that no one will definitely lead. In the end, the convergence will lead. Engineering cannot drive without taking into consideration IT, and IT cannot drive without taking into consideration engineering. The challenge is to create a culture of collaboration between the two or to merge the two aspects in new roles. It will take time since typically engineering and IT have different mindsets and approaches to solving problems.

Looking into the future, how will technology change your organization or other organizations over the next five years?

Luigi de Bernardini, CEO, Autoware: If two years ago I would have responded that technology was for sure modifying our organization slowly and continuously, after the COVID emergency I believe that technology will significantly transform our and all organizations. More than in the past it will be all-around people. In a service company like ours, but in a manufacturing company, as well, technology will be key in enabling and enforcing collaboration between people. It will support communication and sharing of information, of course, but mostly it will support data-driven decisions. The increased need to keep people aligned will grow the need to align them on data and make the collaboration in taking decisions based on analytics. Technology will not only change the way people will do things, but even the way people will look at things. It will impact the company culture, and the transformation will not be painless.