Machine vision applications have been on the rise for some time now. The emergence of smart cameras and more sensible, easier-to-use software have a lot to do with that.

"Machine vision developers, particularly those who face a tight schedule and have to quickly move on to the next project, turn to fully integrated development environments because it not only lets them configure the inspection task without traditional coding, but also allows them to communicate with other automation equipment and enterprise systems, and create the operator interface," says Pierantonio Boriero, product line manager, Matrox Imaging. "These developers now want to leverage the greater processing power of more traditional computers to perform more complex inspections and/or achieve higher inspection rates. They also want to lower the cost for projects involving multiple inspection points by using regular industrial cameras connected to a central computer. This is why our Design Assistant software is being adapted for deployment on not just smart cameras."

SEE ALSO: Easier Machine Vision

Smart cameras combine a digital camera, processing, software, and communications in one small package. "These cameras move vision processing into the camera and return results rather than — or in addition to — images," adds Ben Dawson, director of strategic development at Teledyne Dalsa. "They're an excellent choice for a machine vision system to do tasks such as gauging or visually detecting part defects. Smart cameras continue to become faster, smaller and easier to integrate. Their software continues to improve, and expands the smart camera's applicability beyond manufacturing quality control. The convergence of smart mobile devices and machine vision allows small, fast and inexpensive machine vision systems that are perfect for many machine vision tasks."

Compact USB 3.0 cameras with CCD and CMOS sensors with a C/CS lens mount, trigger and digital I/0 inputs are available with resolutions from VGA to 5MP. Integration into existing applications takes only a few lines of code. Drivers for LabView, Halcon, DirectX, Twain and WDM are included. The cameras ship with drivers for Windows XP, Vista, 7 and 8, SDK IC Imaging Control 3.2 (.NET and C++ class library) and IC Capture.

The Imaging Source

+49 421-335-91-0

FH-Series vision system is available with 0.3M, 2M and 4M pixel resolution, and has an advanced, new algorithm that enables high-speed, stable measurement of target objects with bad focus and random rotation. It has a built-in camera interface, EtherCAT communication interface to PLC, and extensive measurement tools. It includes independent image capture trigger input for up to eight cameras.

Omron Industrial Automation

(866) 88-omron

PCIe-8236 and NI PCIe-8237R two-port GigE Vision frame grabbers have PoE technology. 8237R has LabView FPGA-enabled isolated digital inputs and outputs, and bidirectional TTL lines for custom counters, PWM signals and quadrature encoder inputs. Both are compliant with isolation specifications in the PoE standard to provide additional safety for the vision system and its operators.

National Instruments

(800) 258-7022

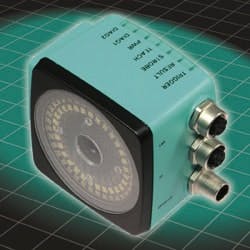

BVS vision sensor with built-in infrared lighting and integrated daylight filter eliminates problems with changing lighting conditions. The sensor’s light is invisible to the human eye, removing intrusive flickering, helping prevent the need for shielding. It is safe for the eyes and certified for CE EN 62471:2008;

Balluff

(800) 543-8390

Xtium frame grabber series uses PCIe Gen2 image acquisition over Camera Link, Camera Link HS, and CoaXPress, delivering a bandwidth of more than 1.7 GB/s, while supporting PCIe Gen 1.0 slot at 850 MB/s. On-board, Data Transfer Engine (DTE) produces maximum bandwidth without specialized motherboards or chipsets. Free Sapera Standard tools run-time license includes advanced image processing and analysis functions.

Teledyne Dalsa

(978) 670-2035

Design Assistant 3.0 flowchart-based integrated development environment (IDE) for Iris GT smart cameras simplifies HMI design with ready-made operator view layouts. Analysis status step consolidates decision-making, and simplifies flowchart design, while filmstrip views ensure that previously analyzed images are close at hand. Monitoring and controlling multiple cameras is via an HMI application and provides support for Profinet communication.

Matrox Imaging

(514) 685-2630

EyeSens vision sensors, with selected commands of the EyeVision image processing software, are equipped to recognize SMT Pin-1-Position and also for OK/NOK electronic component inspection. The sensors have an integrated lens with 6, 12 or 25 mm focal length and an integrated illumination of 8 LEDs, with resolution of 782x486 or 1280x1024 pixels.

EVT Eye Vision Technology

+49 721-626905-82

BIS510 Vision Sensor provides simple monitoring of the correct sheet sequence in collating, folding and binding machines. The sensor includes a camera, illumination LEDs, and an evaluation unit with digital input and output signals, as well as a network interface. It has integrated error image memory, and provides image and barcode recognition at up to 10 pages/s, with a maximum sheet speed of 4 m/s.

Pepperl+Fuchs

(330) 486-0001

Machine-mountable remote display for iVu Vision products enables users to view the iVu sensor image remotely, and serves as a constant monitoring and user programming interface, without interference from electrical noise. The display has a 3.5-in., diagonal, color LCD flat-panel touchscreen, and 60° left and right, 50° up, and 55°down viewing angles. Two LEDs on the remote display provide feedback of the remote sensor operation — one for Power/Error, and the other indicating inspection Pass/Fail.

Banner Engineering

(888) 373-6767

Blackfly GigE POE cameras have global shutter CCD sensors. BFLY-PGE-05S2 supports 808x608 resolution at 50 fps. BFLY-PGE-09S2 supports 1288x728 resolution at 30 fps. They run at cable lengths to 100 m with Gigabit Ethernet, are compatible with third-party imaging libraries via GigE Vision standard, and provide temperature and status monitoring, in-field updatable firmware, color interpolation, look up table, gamma correction and pixel binning.

Point Grey Research

(604) 242.9937

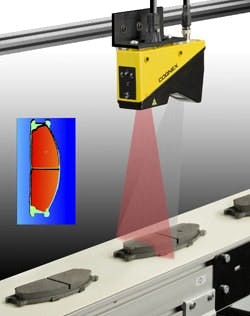

DS1000 3D laser profiling system calibrates real-world units of measurement for inspections too difficult for two-dimensional machine vision. It reads embossed or raised characters, verifies the presence of low-contrast items in boxes or packages, identifies surface defects and chips with low or no contrast, measures heights and tilts of components to determine misalignment, and calculates volumes and dimensions for food portioning.

Cognex

(508) 650-3000

Cyton CXP4 four-channel frame grabber based on the CoaXPress standard has Gen 2.0 x8 PCI Express bus interface on its back-end for high-speed access to host memory in multi-camera systems. It supports simple triggering modes and complicated, application-specific triggering and control interactions within any hardware environment.

BitFlow

(781) 932-2900

IV vision sensor combines some functionality of machine vision and traditional sensors. Standard equipment includes high-intensity illumination, high-performance lenses, and eight sensors. The camera selection includes close-, medium- and long-range models. Navigator setup software can be used with any PC.

Keyence

(888) 539-3623

Four to the Core

EOS-1200 Gigabit PoE embedded vision system has Intel Core i7 quad-core processor, providing four independent Power over Ethernet (PoE) ports with data transfer rates to 4.0 Gbps. It supports IEEE 1588 precise time protocol, enabling synchronization with multi-camera acquisition.

Adlink Technology

(800) 966-5200

AM-201GE (monochrome) and AB-201GE (color) GigE vision cameras are built around Kodak KAI-02150 quad-tap sensor, providing 1920x1080 resolution at 38.3 fps for 8-bit monochrome or raw Bayer color output. AB-201GE can perform in-camera color interpolation to provide YUV 4:2:2 packed color output at 26.6 fps, or 24-bit RGB output (8 bits per color) at 17.7 fps. Also, 10- and 12-bit output is selectable.

JAI

(800) 445 5444

3CCD progressive scan cameras for color area scan machine vision applications include TF5P2 with VGA, 659x494 pixel output at 59.94 fps, while IK-TF7P2 provides XGA, 1024x768 pixel output at 29.18 fps. They have electronic noise reduction, digital shading correction, dual power input (PoCL or 12 Vdc), C-mount lens mount and onscreen and remote RS-232 control.

Toshiba Imaging Systems

(810) 357-5022

Quality inspection system sequence plans are created using the integrated CoDeSys PLC with the standardized languages of IEC 61131-3. Servo controllers can be activated directly via CANopen. SBOx-Q communicates with numerous controllers using standardized software interfaces via Ethernet (TCP-IP, Easy IP, Telnet,

Modbus TCP) and CAN. Up to 256 inspection programs can be stored, each

with 156 inspection features. Optional functions include OCR text recognition, reading of barcode and data matrix codes.

Festo

(800) 993-3786

Fieldeye II, all-weather, CCD monitoring cameras have SUS316L enclosures, sensitivity at minimum illumination of 0.5 lux, zoom magnification of 36× optical and 20× digital, and 650 TV lines horizontal resolution. Video data can be transmitted over a single coaxial cable carrying multiplexed video and control signals, or via an Ethernet network using a video server.

Yokogawa

(800) 888-6400

Datasensor SVS vision sensors have a frame rate of 60 fps (60 images/sec), Ethernet communication, a teach button, 640x480 pixel resolution and nine inspection tools, including pattern match, positioning verification, edge count, contrast comparison, 360° pattern match, contour match, width comparison, brightness check and character verification. The smart vision sensors are available in two product lines. SVS1 models provide setup via handheld configurator, and SVS2 models can be connected to a PC and offer multiple controls.

IDEC

(800) 262-idec

VC nano camera series is based on a board populated on both sides to reduce dimensions to 40x65 or 80x45x20 mm. Models are available with remote camera head and IP68 enclosure, including lenses and lighting.

Vision Components

+49 7243-216716

PSENvip camera-based mobile protection system monitors press brakes. Installed on the upper die, the system detects any foreign body in the protected field between the transmitter and receiver. The visible light beams are transmitted to the receiver via a telecentric lens (vision parallel). It is insensitive to reflections and external/diffused light, as well as vibration and temperature stratification.

Pilz Automation Safety

(734) 354-0272

Opal Series 1–8 Mpixel CCD cameras are compliant with the CoaXPress digital interface specification that allows transmission of high-speed data from a camera to a frame grabber at up to 6.25 Gbps over a single coax cable. For communication from host to device, a 20 Mbps uplink allows for control and configuration data. Power is provided over the cable at 24 V, up to 13 W per cable.

Adimec

+31 40-2353900

uEye UI-5490HE GigE camera has optional 90° angled housing for flexibility in tight spaces. It’s capable of 10 Mpixel images composed of 3840x2784 pixels with 1.67 µm square pixels at 8 fps. Image data from Aptina ½-in. CMOS sensor is output with up to 12-bit depth per channel. An internal FPGA has 64 MB image memory. Features include binning and area of interest, which allow 37 fps at 1920x1080 resolution.

IDS

(781) 787-0048

PCIe x4 frame grabber supports Basler’s A406k/kc Camera Link camera at its full bandwidth. It reaches a transfer rate of 837 MBps in a 10-tap, full-configuration mode at the camera’s full 2320x1726-pixel resolution and repetition rate of 209 fps. Data is transmitted via a direct memory access (DMA) channel into the host RAM, so additional processing for image reconstruction is not necessary.

Silicon Software

+49 0621-789507-0

Condor 1000 MS5 for image capture of visible and near-infrared bands combines five sensors on a spectral separation prism to cover the red, green and blue bands; two additional sensors cover the near-infrared range. It supports frame rates to 150 fps, maximum bandwidth of 210 MBps and hosts Camera Link, GigE and optical fiber interfaces. The sensors can be individually controlled. It supports five 32-bit processors, five multi-pixel coprocessors, and onboard processing for high volumes of data.

Alternative Vision

(520) 615-4073

allPixa color line scan camera increases line frequency to 96 kHz, with maximum transfer rates of 450 MBps. Trilinear CCD color line scan sensors with a pixel size of 10 µm enable image capturing with 1024-, 2048-, 4096- and 7300-pixel resolutions. The resolution of the A/D conversion is 14 bit, and the camera has a flexible programmable, digital I/O interface for LVDS, LVTTL, RS-422 signals, alongside trigger input and output.

Chromasens

+49 (0)7531-8760

Leaders relevant to this article: