Stuart Shepherd talks about his 46-year robotic journey

Key highlights

- Stuart Shepherd spoke with Control Design after being recognized as the winner of the 2025 Engelberger Award for Leadership, recognizing his 46 years of contributions to manufacturing automation.

- An awards dinner, where Shepherd and Dr. Peter Corke will receive their Engelberger Awards, will take place at Automate 2025 in Detroit.

- Shepherd emphasizes the increasing importance of AI in enhancing the ease-of-use, reliability and downtime recovery of robotic automation in industrial settings.

Stuart "Stu" C. Shepherd, co-founder and president of Shepherd Solutions, was selected as the winner of the 2025 Joseph F. Engelberger Robotics Award for Leadership. He will be recognized for more than 46 years of transforming manufacturing in the Americas through robotic automation and capital equipment-related new business development, including past service as chairperson of the Robotic Industries Association (RIA) and the Association for Advancing Automation (A3).

Dr. Peter Corke, distinguished professor emeritus at Queensland University of Technology, was selected as the 2025 Engelberg Award for Education winner for his impact in robotics education and research.

Automate 2025, featuring more than 800 suppliers in the free exhibit hall, as well as a paid conference program, will take place May 12-15 in Detroit at Huntington Place.

The Joseph F. Engelberger Robotics Awards are named after the late Joseph F. Engelberger, recognized by many as the founding force behind industrial robotics. Since 1977, these awards have been given to 141 robotics leaders from around the world for excellence in technology development, application, education and leadership.

The winners are selected by a panel of industry leaders based on all present and past nominations from the industry and are voted on by the past chairs of the RIA, which became part of A3 in 2021. A3 administers the award, and each winner receives a $5,000 honorarium, a commemorative medallion and a plaque.

“This year’s Joseph F. Engelberger Robotics Awards honorees have dedicated their lives to our industry, and so many of us have benefitted from their contributions,” says Jeff Burnstein, president of A3. “Stu’s leadership and foresight over the past 46 years have been instrumental in transforming manufacturing. Peter’s educational resources and research have shaped the work of robotics engineers for many years and led to immeasurable industry advancements.”

In addition to having chaired both A3 and RIA, Shepherd continues as an A3 Robotics board member. He is also an R15.05 safety committee member and a member of the American Welding Society (AWS), serving on the D16 Robotic and Automatic Welding Committee.

Prior to founding his consulting firm, Shepherd’s past experience includes automation integration roles at General Motors, a well as sales and leadership roles at FANUC America, KUKA, Güdel and Universal Robots. He’s also held consulting roles at Gain and HowToRobot, which merged in April 2024.

“I am truly humbled and grateful to receive this award,” Shepherd says. “My career in robotics and automation has been both intellectually challenging and rewarding. I’m honored to have been a part of this industry for many years and look forward to watching and contributing to its ongoing success and evolution.”

What does the Engelberger Award symbolize to you, in terms of achievement or recognition?

Stu Shepherd: This incredible honor is an affirmation of my journey as a leader in the robotics industry. I have always believed that if you keep doing the right things to empower teams to act on the real voice of the customer, then you can accomplish great things together.

What got you interested in the field of robotics? Was it early on or something you developed through your studies/career?

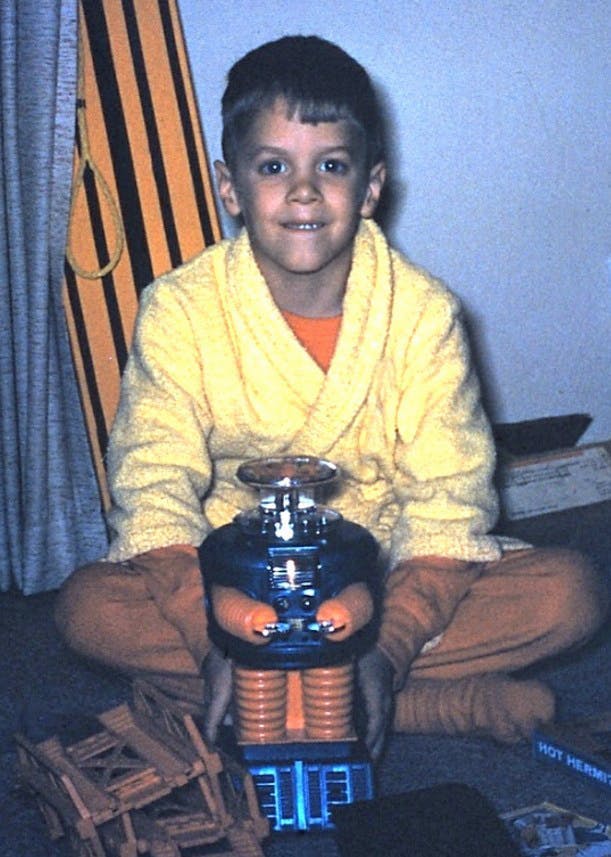

Stu Shepherd: I have always enjoyed science fiction and working on mechanical things (Figure 1). I also demonstrated excellent drafting skills in high school. As a young co-op engineering student at Purdue University and General Motors, I was provided with assignments and mentors that further developed these interests and skills. Upon graduation, I was assigned to my first robotics project for assembling an automotive component, and the rest is history.

What recent robotics developments are of the most interest to you?

Stu Shepherd: I'm very interested in the use of AI to improve robotic automation ease-of-use, reliability and downtime recovery, which have near-term viable use cases. AI uses for machine learning are emerging, but commercial viability is still a few years away.

Other interests are the improvements in sensing technologies, especially LiDAR and event-based vision systems, to improve perception for robotic applications.

Can you talk a little about where the public perception and the industrial perception of robots overlap and where they split?

Stu Shepherd: The public perception of robots remains largely based on what they see in science fiction television or movies or in clever YouTube videos—in a word: humanoids. The public largely does not realize that many of these humanoids or quadrupeds, such as "robotic dogs," are not really autonomous, but are either costumes over actors, computer-generated imagery or telemanipulators. Also, the public may not realize that a humanoid may not be the best form factor, or functional shape, for most use cases.

In some cases, the public is gaining a better understanding of medical surgical robots, where some are semi-autonomous for diagnostics and radiation treatment but still telemanipulators for surgical assistance. They understand that these robotic devices exist and work but in very controlled and expensive environments.

The public and industry have a good understanding of robotic vehicles, or autonomous vehicles or unmanned aerial vehicles, such as drones. Both the public and industry recognize the potential is huge, but the development of vehicles, infrastructure and safety still needs time.

The industrial perception of robots varies dramatically by market vertical.

For large enterprises with large volumes of business, especially in automotive and warehouse/3PL markets, robot technology is well-accepted, and adoption rates continue to increase.

For small- to mid-sized enterprises (SMEs), especially those with low-volume and high-mix business volumes, robotic automation may still seem mythical. However, many of these businesses may be surprised at how affordable and easy-to-use pre-engineered or standardized robotic applications have become. SMEs can now get into the game.

While robots will always be amazing marvels of machine engineering in their own right, they also have become components in industrial equipment. What are some of the more intriguing examples of robot integration in machinery or work cells that you've seen?

Stu Shepherd: There are robot systems as motion platforms for motion simulators or entertainment ride systems. The perceptual sensations, flexibility in motion and reconfiguration or redeployment capabilities are nearly limitless.

There are robot systems for high-volume primary food preparation and handling. Properly constructed and maintained robots can be more hygienic, precise and faster for high-volume food manufacturing, especially for multi-shift operations in farm fields or orchards, vertical farming, or protein processing factories alike.

Robot systems exist for near-autonomous truck trailer unloading or reloading. And space or underwater exploration robots—"rovers"—are much easier to deploy and safer. And there are nanorobots for more precise applications in human diagnostics and treatments.

Get your subscription to Control Design’s daily newsletter.

How might the merging of robotics and agentic AI change the adaptability of manufacturing and even affect the fluidity of engineering capacity?

Stu Shepherd: AI is being adopted at an increasing rate to solve data-related solutions at faster rates and with increased reliability, especially for vision or perception applications. For example, synthetic data and digital twins are enabling faster programming and deployments.

AI-enabled machine performance monitoring can improve robot motion efficiency leading to improved system reliability and durability. Likewise, these performance-monitoring capabilities can provide insight and alerts on root causes of performance degradation.

With the perceived push toward more autonomous manufacturing capabilities, will the collaborative ability of a cobot become redundant and unnecessary, or do collaborative robots have a role in manufacturing applications that run lights-out 24/7?

Stu Shepherd: The term “cobot” is really an obsolete term. Cobots are frequently used in non-collaborative applications due to their ease-of-use or ease-of-purchase or form factor. Likewise, sensors can be added to traditional industrial robots to enable them to be used in collaborative applications.

In 2025, both European (ISO) and North American (ANSI/A3, NOM and Z434 ) robot safety organizations have revised and harmonized standards to define "collaborative applications" which can be created with robots that are either (a) force and speed limited or (b) distance and separation monitored. Therefore, what I see is a convergence of controls and sensing technologies between industrial and collaborative robots, which will lead to significantly more collaborative applications in all markets.

What is the next big thing in robotics?

Stu Shepherd: Everyone is searching for what's next, and maybe wasting valuable time and money chasing big ideas like humanoids. The facts are that there are many well-developed, cost-effective and easy-to-use solutions available today, but many business decision makers can't seem to justify the investment, or they perceive the risk for implementation as too high. I see that the next big things in robotics are for suppliers to do a better job in providing validation or proof for total cost of ownership (TCO), plus improving ease of use. Likewise, decision makers need to learn more about the value of automation beyond just manpower cost offset and how to specify and source equipment that is easy to use.

Why should younger generations be more attracted to science technology, engineering and mathematics (STEM) curricula, specifically robotics, in the future?

Stu Shepherd: Many students and their parents may think that STEM curricula lead to opportunities in just traditional manufacturing jobs. STEM-related skills, especially in robotics, can now create connections between students' interests to careers in an ever-widening array of industries inside and outside of manufacturing. The earlier that students can connect their passions to their career choices, the better they will perform and the happier they will be in their work lives. Students and their parents can investigate STEM programs in their community via Project Lead The Way (PLTW).

Articles and interviews with past Engelberger Award winners

- 2015: Raffaello D'Andrea

- 2017: Daniela Rus

- 2018: Esben Østergaard

- 2022: Bertil Thorvaldsson, Michael P. Jacobs

- 2023: Roberta Nelson Shea, Jeff Burnstein

- 2024: Joe Gemma

Next steps

- Investigate the program for Automate 2025 in Detroit, May 12-15, to identify relevant conference sessions and exhibitors focused on AI in robotics and advanced sensing technologies.

- Reflect on current automation projects to consider how integrating AI for improved ease-of-use, reliability and downtime recovery could provide significant benefits and explore potential pilot applications.

About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: