The word encode means “to convert.” Simply put, an encoder takes a feedback signal and makes it into something readable and understandable. Encoding is equivalent to translating.

Motion-control applications use encoders to report position back. For instance, in rotary motion, a shaft moves in a circle, and, each time the circumference is met, engineers can put a value or count on that mechanical rotation.

Get your subscription to Control Design’s daily newsletter.

If you sum the rotations, you have moved a distance related to the number of rotations. This count can be related to count, speed, distance, position, direction. This is a simplified view of converting a mechanical movement to an electrical signal that can be measured.

How do encoders work in motion control?

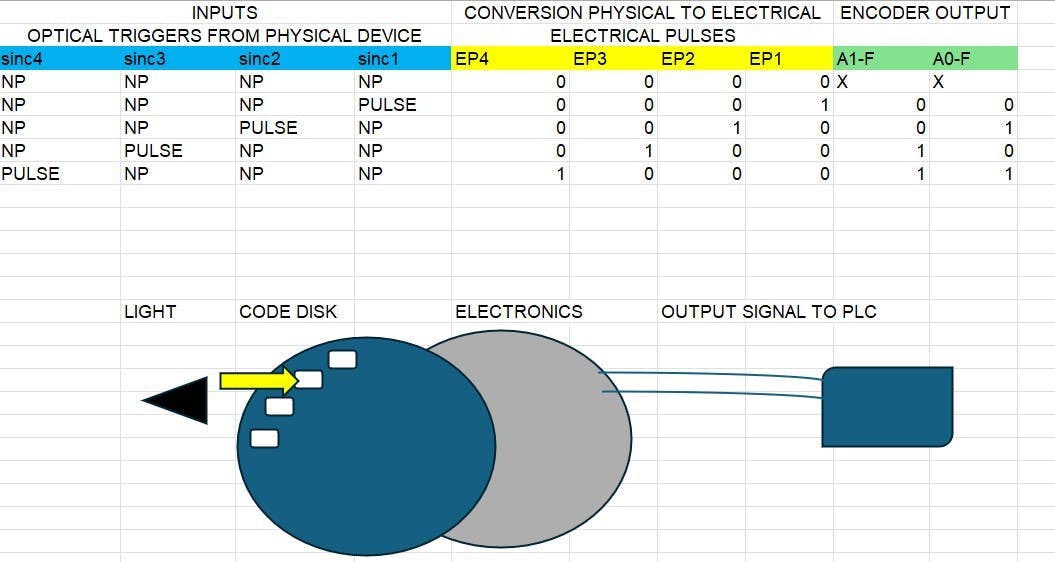

Most machine builders and controls folks would relate encoder to motion, but how do encoders really work? How an encoder works depends on the type of technology used. For instance, encoders may be mechanical, magnetic, resistive or optical. Optical is most common in today’s world. A light-emitting diode (LED) is used to emit a light beam, and, when the shaft rotates, the light shines through a line on the disc, and a pulse is created. When the light is on, the binary response is one. When the light is off, the binary response is zero. Mechanically, the disk that the light looks through may be modified for the resolution needed.

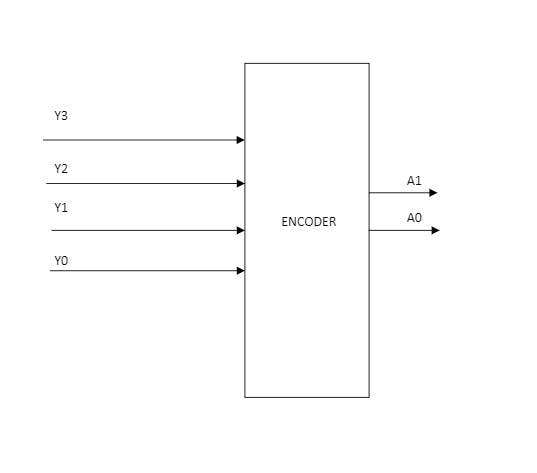

As an example, let’s look at digital logic. For digital logic, picture a 4 to 2 conversion (Table 1).

In the box representation, this would be OR gates with the logic of:

If Y1 or Y0 then A0 =1

If Y2 or Y3 then A1 = 1.

This can be expanded to represent however many inputs (Figure 1). Here, we just want to show how four inputs can be encoded to represent two outputs. This is the same idea used with an encoder.

These examples are simple, but encoders are the backbone to actuation and precision movement (Figure 2). For instance, robotic encoders may have precision to the point of arcseconds, or, for example, a fraction of a degree such as 0.18 degrees.

Encoders defined and their role in automation

Encoders have been under development since the 1960s and are continually being updated based on electronics advances and societal needs. Robots or computer numerical control (CNC) would not be possible without encoders.

The purpose of this explanation is to define an encoder and show the transition of the mechanical response to the electrical response. Also, the pattern can be whatever is called for.

For instance, absolute encoders use a code disc that allows markers to track a unique binary code for each position. Many people think this means you do not have to “home” an absolute encoder. Initial configuration still requires zeroing and creating a reference for a start position so that the absolute encoder may store the expected reference for future power-offs.

In short, if the controls engineer recognizes that a physical pulse can be converted to a binary pattern and then referenced in a real-time program with units, then they are on their way to understanding encoders.