Distributed I/O: a User Profile

By Jim Taylor, Venture Development corp., and Joe Feeley, editor in chief

This is the third and final article we’ve assembled on the findings of a recent market study about input/output technologies conducted by Venture Development Corp., and in which Industrial Networking subscribers participated.

We previously saw confirmation that users are moving away from local I/O hard-wired at the controller and embracing distributed/remote I/O connectivity via buses and networks. The study shows, for now, local I/O still accounts for the largest segment of connections for DCS, PC-based, and PLC-based systems, and they still are the majority in the DCS and PLC segments. This all should change by 2010. The study points out that displacement of local I/O certainly provides a growth opportunity for the distributed I/O product maker, but the expanding use of devices with bus/network interfaces already embedded in them decreases the rate of separate device growth. See Table I for additional detail.

Functional Requirements

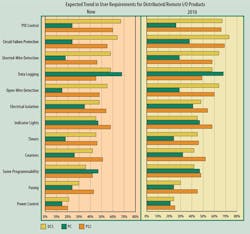

The study asked respondents the basic question: What do you use distributed I/O for now, and what changes do you expect in that regard between now and 2010?

For DCS and PLC system users, PID control was the most-named functionality identified as needing remote I/O, although by narrow margins. The PC-based system users identified data logging as the most-pressing current need, and it was clearly ahead of all other functional requirements.

The expected changes in emphasis during the projected period are largely modest, with all users citing various types of increased physical circuit-failure detection as having increased adoption. See Figure 1 for details.

Gonna Be a Resolution

Study participants were asked to predicts their future and anticipated data resolution requirements for distributed I/O products.

The PC-based users currently have more concerns about data resolution, with two-thirds of them right now needing 16-bit or higher resolution. This compares with 52% of the DCS users and 49% of PLC users. A full 38% of PLC users state their current requirement to be 12-bit resolution.

The study cautions that these movements to higher resolution, while clearly a real trend, might overstate the actual need by 2010. In many cases, newer products will by default offer higher resolution at prices competitive to lower resolution products, some of which will simply become obsolete. Users will buy and incorporate the higher resolution products even if actual requirements remain the same.

The clear upside is that users then will have tools by which to evaluate whether they can improve their processes via better data. A more complete summary is found in Figure 2.

Little Boxes

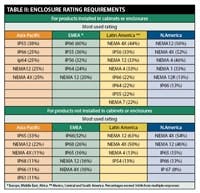

The study branched out to ask the participants about the types of enclosures that the distributed/remote I/O applications will require, providing a sense of the environmental operating issues at hand. The results were also parsed by geographic regions.

For products installed in cabinets or other enclosures, a large percentage of respondents in all the regions selected products with a high level of environmental protection. The reasons for specifying devices with higher protection levels, even when the devices are installed in enclosures, might indicate a desire for flexibility for potential future mounting applications, the declining, more-attractive cost of ruggedized devices, and the possibility of concerns about the limitations of the enclosures.

Not surprisingly, users of products not installed in cabinets or other enclosures most often specified devices with protection against water and dust. Rating of NEMA 4 and NEMA 4X were most frequently identified. Table II provides details.

Regulatory Requirements

The study participants were asked to specify the safety agency and regulatory requirements they followed when specifying distributed/remote I/O products. The responses, noting multiple regulatory compliance requirements, were broken down by geographic region.

Software Preferences

To round out the picture, the participants were asked to note programming language preferences for implementing distributed/remote I/O in their applications.

IEC 61131-3 programming languages were by far the most popular with the DCS and PLC system users. IEC 61131 Function Block Diagram was noted by 56% of DCS users, although 30% answered that they used proprietary programming languages from the DCS supplier—the second largest response. Nearly a quarter of the DCS users said they use the IEC 61131 Structured Text, Instruction Set, and/or Ladder Logic language as well.

For PC-based systems, nearly half the respondents selected Visual Basic and/or C++, and 26% specified Basic. IEC languages trailed far behind with the PC users.

Traditional ladder logic was specified by 71% of the PLC users, but IEC 61131 Ladder Logic was close behind at 61%. Figure 3 provides the details.