We're ready to start changing out electromechanical relays (EMRs) with solid-state replacements (SSRs) in our installed base during troubleshooting or routine customer service calls, as well as use them in an upcoming new-generation machine line.

We're receiving mixed reaction from the installed base and even from a few potential new customers that we're after. The device prices are higher, and we have some heat to dissipate, but given the solid-state device's advantages in service life, noise generation and arc resistance, we think we'll provide notably better performance. Are there applications for which there are justifiable reasons not to make this change?

—From June '14 Control Design

Answers

EMRs Have Their Place

There is always a tendency to resist change, even while solid-state relays could work in many applications. However, there are some types of applications in which electromechanical relays are definitely preferred, including whenever:

leakage current from the SSR is a concern;

- heat could be an issue;

- normally closed contacts are required;

- a relay with more than one pole is desired.

You should consider what devices are connected to the control and load sides of the relay. Electromechanical relays are far more forgiving than solid-state relays if voltage or current spikes are possible. A quick specification review should be performed when substituting devices. Electromechanical relays typically will have a higher contact-current rating and varying pilot-duty ratings compared to the comparably sized solid-state version.

Bryan Knapp,

Product Manager for General-Purpose Relays,

Rockwell Automation

Also Read: Relays Fall, Expected to Get Back Up in 2013

Solid for Solid-State

Solid-state relays (SSRs) are different in operation from mechanical relays that have movable contacts. SSRs employ semiconductor switching elements such as thyristors, triacs, diodes and transistors. SSRs consist of these electronic parts with no mechanical contacts. Therefore, SSRs have a variety of features that mechanical relays do not incorporate. The greatest feature of SSRs is that they do not use switching contacts that will physically wear out. SSRs are ideal for a wide range of applications due to the following performance characteristics:

- They provide high-speed, high-frequency switching operations;

- They have no mechanical contact failures;

- They generate little noise;

- They have no operation noise.

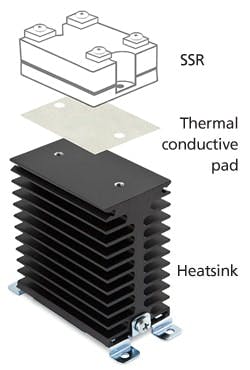

Figure 1: The main cause of application failure with SSRs is not properly mounting the SSR using a heat sink.

However, SSRs do have some limitations that need to be considered when designing the relay into an application. These limitations include the following characteristics:- They're never truly off;

- a small leakage current might be present at the load;

- When they fail, SSRs will mainly fail as a short and no longer control the load that is operating;

- A multi-pole SSR is two or more SSRs in parallel and might not operate in tandem like an electro-mechanical, multi-pole relay will;

- They generate heat during operation.

Since their introduction, SSRs have gained acceptance in industrial applications. These applications include circuits that previously had been the main operating area of the electromechanical relays (EMR) or the contactor. The SSR is increasingly employed in industrial process control applications, such as temperature control, lamps, solenoids and valves. For those EMR applications requiring two- or three-pole operation, today's SSR technology can incorporate two or three poles into one unit as opposed to using two or more single SSRs. The benefit of this is that the application can switch all sets of contacts at the same time like an EMR.

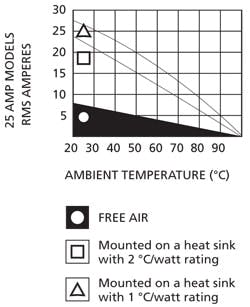

The main cause of application failure with SSRs is not properly mounting the SSR using a heat sink (Figure 1). The load characteristic is also a concern that will cause application issues with SSRs. The current requirement characteristics of the load should be carefully considered when using SSRs as a switching solution (Figure 2).

Using SSRs with resistive loads, DC loads, lamp loads, capacitive loads, or motor and solenoid loads all provide challenges that can be overcome in circuit design. The possible cost difference and the increased heat that can be generated by SSRs do not prohibit the SSRs installation. SSRs can be installed in almost all applications currently using an electromechanical relay. With proper circuit design, I would suggest that the SSR has more benefits for use in industrial applications then an EMR.

Bruce Fink,

Product Engineer,

Omron Automation & Safety

SSRs Aren't Perfect

The semiconductor-based SSR has many advantages over electromechanical relays, but two factors inherent to SSRs—leakage current and operational temperature limits—can preclude using them for some applications. Leakage current is caused mainly by the SSR's snubber circuit. When in the "off" state, the relay will exhibit a small amount of leakage current, typically a few mA. Although slight, this current can keep some loads from turning off, especially ones with a high impedance such as a small solenoid or a neon lamp, which have relatively small "hold-in" currents. Leakage current also can cause circuits with SSRs that are switched off (electrically open) to still have potentially hazardous voltages on the outputs, in particular for SSRs that switch high voltages.

Figure 2: The current requirement characteristics of the load should be carefully considered when using SSRs as a switching solution.

For applications requiring zero-leakage current, consider using an electromechanical relay or an SSR with a mechanical switch and fuses. Note that problems using SSRs with high-impedance loads usually can be addressed by placing a power resistor sized for eight to 10 times the rated maximum leakage current for the SSR in parallel with the load.Semiconductor-based relays become less efficient as the relay temperature increases, so the current rating for an SSR is de-rated, or reduced, based on the ambient temperature. Add to this the fact that an SSR generates heat in the "on" position, and heat management becomes an important consideration. An SSR is typically mounted on a heat sink to dissipate generated heat, yet even when heat sinks are used in some applications with high ambient temperatures or environments, such as an enclosure that is exposed to direct sunlight, the SSR might not be able to supply the maximum steady-state current required. Using different types of enclosures, adding air conditioning and other steps to reduce ambient temperature can be cost-prohibitive. For such an application, an electromechanical relay should be considered.

Bill Steffens,

Product Support Group Team Leader

Opto 22

[We received the following responses when we posted the problem to LinkedIn's Automation Engineers Group.]

Fail Safely

Electromechanical relays do have a very clear safe-failure mode. When they fail, they almost always fail deenergized, so they are more "adequate" for safety applications than regular solid-state output devices. Those devices could fail dangerously (in short circuit) or safely (open output). So if safety is a concern, either keep the relays or replace them with a good certified safety PLC (way more expensive).

Vitor Finkel,

CAP,

Teacher, Instrumentation and SIS

Detect Critical SSR Failures

Most failure modes of solid-state devices cause the SSR to fail short. Analyze each output circuit and device that uses an SSR. Not all outputs will be critically affected if the SSR fails shorted. Decide which outputs must be protected in case of a shorted SSR. Your electrical design should include a means to detect and disconnect electrical power from those devices. Perhaps use a contactor that can open if SSR failure is detected—or use circuit protection on over-current.

Gary Foster, engineer,

GP Strategies

EMR Easier to Troubleshoot

Years ago, out of necessity, we started with machine vision systems built from PCs, frame grabbers, big cameras with proprietary buses, bad software, etc. We've been able to simplify and move to smart cameras. Some of our sensing applications are only about color and shade, so we see possibly more simplification, even though we expect to need to provide more speed and sensitivity going forward. Are there practical differences and limitations between what some companies call smart color cameras and others call smart color sensors. Are we beyond RGB at this point?

SEND US YOUR COMMENTS, SUGGESTIONS OR SOLUTIONS FOR THIS PROBLEM. We’ll include it in the October 2014 issue, and post it at ControlDesign.com. Send visuals if you'd like—a sketch is fine. Email us at [email protected]. Please include your company, location and title in the response.

HAVE A PROBLEM YOU’D LIKE TO POSE to the readers? Send it along, too.

Thomas Stevic,

Controls Engineer,

Cincy Integration & Automation

It's New Devices for Me

I would always favor new electronic devices. These relays can be set and operate more accurately. The time delays are far superior. Conventional EMRs have only one advantage in our region: operators and technicians are more comfortable setting, operating and using them. With electronic relays, most of the time. senior engineers also have to check the settings. In SCADA interfaces, only compatible relays shall serve the purpose. In isolated applications, EM relays can be used, but in a larger system, I am all in favor of relays with a computer interface.

Shashi Bhargava,

Owner,

Johns Electric

SSR for Most Applications

Electromagnetic relays are more reliable for securing the system and adopting a fail-safe system. Solid-state devices are fast, but have some disadvantages when it comes to implementing fail-safe systems. In normal controlling systems, it's better to use solid-state relays, as they occupy less space and are faster then conventional EM relays.

With any new complex electronic system, diagnosis becomes complex, but it doesn't mean that we should not go for new systems. We should upgrade systems regularly ensuring that they are more efficient and advanced than the older ones. We can consider what are the diagnostic and maintenance features it can provide.

Ashish Sharma,

Asst. Manager,

Yokogawa India

To Each His Own

The most important aspects in choosing the right relays, whether EMR or SSR are:

Electrical life—both SSRs and EMRs are good;

- Ambient temperature—EMRs are better for higher temperatures;

- Switching frequency—SSRs are better for higher frequency;

- Environmental conditions—SSRs and sealed EMRs can be used;.

- Isolation/insulation levels—EMRs have better creepage and insulation;

- Switching response time—SSRs are faster unless using zero-crossing SSRs for an ac load.

Ashish Manchanda,

Managing Director,

Finder India

[We received these responses when we posted the problem on LinkedIn's Automation.com group.]

Not for Inductive Loads

I've experienced problems when switching inductive loads, such as solenoids, with an SSR. The back EMF of the solenoid coil can make the SSR output stay on.

Joe Williamson,

Sales Director,

More Control UK

SSRs Do Leak

Leakage currents in SSRs can be a problem, particularly when used to switch PLC or DCS digital inputs.

Dan Mazorra,

Project Engineer,

EMA

SSRs for Alarms

SSRs are used for fast switching with respect to general relays. But their switching capacity is lower than a general relay in most of the brands. These are good for alarm generations. SSRs can burn out when used with inductive loads such as solenoids.

Vijayant Singh,

Automation Project Engineer

You Get What You Pay For

My gut says "you get what you pay for" where solid hardware designs turning on and off a zero crossing (current) cost money, and snubbing transients with appropriate circuitry also cost (some) money. So when using a low-cost electronic control product, there are reasons it is low-cost. If you use a PLC, contact your supplier and explain your application, and I am certain it will provide you with a good solution. Heck, I turn DC motors on and off with 60 amps of inrush, and it gets ugly when you turn them off (they become a generator), but we don't fail.

Don Pieronek,

Owner,

Real Time Objects & Systems

Fail On Is Unacceptable Risk

Recently, I considered this issue on a critical shutdown system and put the use of SSR to one side in favor of an electromechanical solution after research indicated that the typical fail state of SSR is the on state. This was an unacceptable risk for me.

Chris Morony,

Director of Operations,

Central Region Middle East and Africa,

Emerson Process Management

[These responses come from LinkedIn's Indutrial Automation and Process Controls Group.]

Everything Has Its Place

Of course there are. EMRs are not dead, far from it. SSRs are, of course, great, and for many applications it would be silly not to use them. But there will always be the applications where a cheaper EMR would do the job just as well. Are you building a quality product, designed to last? Put an SSR into it. Are you designing a "throwaway" product with a low switching frequency? Put an EMR into it. Yes, we do live in a "throwaway" world.

Stewart Duncan,

Inside Sales Engineer,

Crydom SSR

SSR Great for PID Control

There are pros and cons in most applications. If you want absolute, guaranteed isolation, then nothing can beat an open contact from an EMR. SSRs come with very high isolation voltage ratings, but blocking isn't the same as switching, and some leakage is always present. In many applications, that doesn't matter, so you really need to know what's important in your application. Used within its ratings, on mainly resistive loads, an EMR will do the job for years. You also get the benefit of switching multiple circuits at the same time. Things like four-pole SSRs are pretty thin on the ground.

If severe vibration comes into the equation, an SSR could be the better choice. Also, if the application involves high switching frequencies and/or inductive loads, an SSR could be the only sensible option. In the former, because of zero-contact erosion that an EMR would be subject to, and in the latter because EMRs are limited to a certain number of mechanical operations before the contact tension (spring) weakens.

One instance where an SSR really comes into its own is in PID control of heating elements, etc. In a PID scheme, the load is energized constantly from rest to give maximum rate of temperature rise. Then as it nears the setpoint, the load (i.e., heater) is switched off to minimize overshoot. The control then switches the load on and off to maintain the setpoint. This rate of switching can be fairly rapid and the only practical device is an SSR. But if the heater is controlled by a simple hysteresis switching setup with upper and lower temperature limits, a relay/contactor will do the job just as well if the switching noise isn't an issue.

Frank Seifert,

Senior Technical Consultant,

Mechtric (SA) Pty. Ltd.

More Strengths

Using SSRs with "zero-crossing" switching will virtually eliminate radiated emissions. EMRs can do a NC contact, which is difficult with most SSRs. And another thing EMRs do better is a force-guided relay, as used in safety circuits. I use a lot of MOSFETS in my controllers for switching hydraulic solenoids, and they work well doing that, plus you can apply PWM and current control to achieve a high pull-in and low holding current.

Bob Turner,

Director

Salbay Engineering

Sponsored Recommendations

Leaders relevant to this article: