Dan Hebert is senior technical editor for Control, Control Design and Industrial Networking. Email him at [email protected].

Many manufacturing plants outsource all or part of major capital projects, such as greenfield plants or new production lines. When these projects include a number of machines and a high degree of automation, such as a packaging line, the plant owner has a choice of two main types of outsourced partners—an OEM machine builder or an automation system integrator (SI). A third choice would be an engineering firm, but in this case, the main partner would be the automation division of the firm, so this alternative can be lumped in with the integrator option.

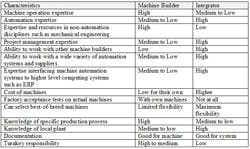

Table 1 compares the two types of outsource partners, and there are other factors besides those listed which drive the decision. In the integrator's favor are production lines with machines from many different suppliers because integrators are used to working with many subcontractors and suppliers on their projects, and machine builders may have trouble working with other OEMs, particularly competitors. If the new line has a high degree of advanced automation, then a system integrator may be a better choice.

Table 1: When these projects include a number of machines and a high degree of automation, such as a packaging line, the plant owner has a choice of two main types of outsourced partners—an OEM machine builder or an automation systems integrator.

If the production line has many machines from one supplier, then the machine builder partnering option becomes more attractive. Another factor favoring the machine builder alternative is very high complexity of the main machines on the production line. This would tend to swing the partnering choice in favor of the OEM building the complex machines, assuming they also offered integration services, as no one knows machine operation as well as the OEM.

Experts With Machines

OEM machine builders claim to have much more specific application experience than system integrators and are therefore better able to take on an overall project. Paul Strebig, controls engineering manager at USNR agrees. Located in Woodland, Washington, USNR builds machines for wood processing, including everything needed to build an entire sawmill with 30 or more machine centers. "The experience and history that OEMs have in their industry is a great advantage since this knowledge allows them to select the best products and solutions for each individual customer," he says. "Most system integrators have limited history in a particular industry. Machine builders specialize in their industries, know how to be efficient and have fast and effective installations and startup."

Figure 1: Headed parts are bowl-fed into OmniTurn lathe for machining. Pins, bolts or hollow or solid rivets can be trimmed, turned or threaded with a load/unload time of about 3.5 seconds.

Deep knowledge of their equipment is also valuable. NC Electronics in Port Orford, Oregon, manufactures OmniTurn CNC turning/milling centers, and it knows how to interface its own systems (Figure 1). George Welch, CEO, explains, "We worked directly with one customer to produce the simplest, most cost-effective solution. The OmniTurn CNC can be configured to interface with various controllers, as well as imaging and gauging systems. Because we're familiar with interfacing the Mitsubishi PLC with our CNC and because we have experience machining parts on the lathe, we saved the customer time and money."

Welch adds that working with an OEM also eliminates finger pointing. "We accept responsibility for the entire system hardware and building the complete system," he says. "In other words, the buck stops with the builder. Also, training, service and repair, as required, are handled directly on a one-to-one basis without needing to train and equip a third-party developer."

John Martin, vice president of engineering at custom machine builder ARC Specialties in Houston, agrees. "Machine and robot builder OEMs that are vertically integrated hold a unique advantage over traditional system integrators. We take full ownership of a project and drive it from conception, design and manufacture to integration and production. There's no mix of hands to point fingers in multiple directions, but instead only one responsible company that understands every aspect of the system." Like many OEMs, ARC Specialties has a large shop, enabling it to test machines and systems prior to shipment (Figure 2).

Figure 2: In-house machine shops like this one give OEMs an advantage over system integrators when it comes to pre-shipment testing.

OEMs also have more resources available than system integrators, says Strebig. "Machine OEMs are better qualified to provide production line system integration since they are able to have tight control of the mechanical, electrical and controls aspect of a project. This control over design allows an OEM to make changes to optimize a complete solution package, whereas a system integrator will be stuck with the equipment they're required to commission."

Bob Fung, vice president of engineering at Owens Design, a custom machine builder in Fremont, California, adds, "System integrators generally buy existing hardware and put the system together. In general, we have a much stronger skill set and the ability to take on much more complex tools. We can create sections of a tool that a basic system integrator can't."

Figure 3: This turning cell uses immediate, post-process part measurement to maintain tolerances as tight ±0.001 in (0.025 mm). A robot loads the parts for measurement and packs them for shipping if they meet specifications.

Conroe Machine is a manufacturer of high precision metal cutting machines, and it often combines its machines with other OEM products to create all or part of an integrated production line (Figure 3). On a recent project, Conroe designed and installed a hard-turning cell for measuring and sorting mud-motor bearings. The cell also boxes and palletizes finished parts.

This brings up the double-edged sword of equipment selection. Matt Wicks, vice president of controls and software engineering at Intelligrated, a builder of material handling equipment in Mason, Ohio, says, "The argument for independent integrators is they pick the best equipment, regardless of who manufactures it. On the surface, this appears to open up competition and drive down initial purchased prices. In the long run, misapplication of equipment and conflicts between machine builders and integrators can lead to increased costs and project delays."

On the other hand, Bill Savela, product manager at Delta Computer Systems, a supplier of motion control systems in Battle Ground, Washington, offers this observation: "A potential drawback to OEM-managed system integration is the need to use a majority of system elements that are manufactured by that OEM. This can limit accessibility to the industry's best-in-class equipment by other vendors and lock customers in to the OEM's product evolution path."

Integrators Know Automation

While there's no argument that machine builder OEMs know their equipment and have great experience integrating their own machines into production systems, system integrators claim they have experience and knowledge, too. In their case, it's in integrating a wide variety of machines into production lines of all kinds and more knowledge about particular plants.

The experience of system integrators in dealing with advanced systems is a prime advantage, says Joseph Snyder, president of Process and Data Automation, a system integrator in Erie, Pennsylvania. "A packaging machine application that requires a couple of simple in-feed and takeout conveyors would normally fall easily within the realm of an OEM," says Snyder. "But as the system complexity increases along with the number of unique players and parts, an SI might be critical to ensuring smooth connection between the pieces. On a very sophisticated system, the SI's experience in connecting to adjacent process areas and business systems might become very important, as most OEMs have not ventured into those arenas. I feel that the chief advantage of SIs over machine builders when installing new lines is their superior automation system expertise, from using and integrating automation hardware and software from different suppliers to tying the automation systems to higher-level customer software such as ERP systems."

This can even affect equipment selection. "On a larger scale, the multi-platform experience of an SI will be hugely beneficial when selecting vendors because the overall production system may require multiple equipment manufacturers, which, in turn, may mean the introduction of different control equipment suppliers," Snyder adds. "If nothing more, the project management discipline, where most established system integrators excel, might be critical for simply keeping the project moving forward."

Gary Kirckof, system engineering group manager at control equipment supplier Beckhoff Automation, says, "Some OEMs offer integration services just to secure the sale of their primary product. By contrast, the primary product of an independent integrator is integration. Pure integrators are freer to select equipment from multiple vendors. OEMs, on the other hand, may place a higher priority in specifying their own equipment to meet the goals of engineering efficiency, maintainability and spare parts management."

Del Younglas, owner of Texagon Services, an SI in Westlake, Texas, agrees. "Texagon Services can evaluate the project with the customer and make individual decisions of what component parts are to be retained and what should are to be replaced," he explains. "In a majority of Texagon retrofits the customer chooses to retain the existing motors and drives and replace the CNC controller only, which can be a significant savings. Most machine builders and OEMs that do retrofits remove all electrical equipment including the CNC controllers, motors and drives and replace them with their preferred complete system. Economically, this is not the end user's best choice."

CMD, a machine builder OEM in Appleton, Wisconsin, designs and manufactures converting machines for the blown-film and flexible packaging industries. Examples include continuous-motion machines for making bags and pouches and various types of automation equipment to package products made by the machines.

Chris White, project manager at CMD, explains, "Our automation systems range from taking finished product from one machine and placing it into another machine to fully customized automation using Cartesian and SCARA type robots."

On the integration front, White says, "CMD provides integration services ranging from integrating CMD equipment for specific product requirements to integrating our equipment with various suppliers of upstream and downstream equipment. Types of equipment we may integrate to complete a line include dosing units, extruders, bag making equipment, conveyor systems, cartoners and case packers. We'll integrate manufacturing lines that contain CMD equipment, or a combination of CMD and other suppliers' equipment—any combination the customer requires to produce the best solution."

White thinks OEM machine builders are better able to perform integration. "OEMs typically have a very thorough understanding of the equipment and processes involved to provide the best solution," he says. "Many times if an outside integrator steps in to integrate multiple pieces of equipment they will not fully understand the manufacturing process."

One example in the bag converting field is how to minimize impact on production if a portion of the line goes down. "If a production line is cartoning and casing rolls of bags automatically, what happens when the cartoner jams?" he asks. "An integrator without experience in the process may say, ‘If the line stops, clear the jam, and start the line back up.' The integrator may not realize the difficulties of starting the line back up, especially if it's in line with an extruder, which may take a half hour or more to get back into production."

He notes, "An OEM integrator very familiar with the process will have provisions to keep the line running and to introduce product back into the system while clearing the jam. Other things the integrator must consider are how to cull defective product; how to handle variances in product size, shape, colors and densities; and how to inspect for some of these items."

And OEMs have better access to non-automation resources. "Typically a machine builder OEM is going to have access to machine tools to make mechanical integration parts," he explains. "The machine builder has purchasing leverage to buy manufactured parts and expedite deliveries of parts. For example, if a controller goes bad during integration, an OEM has access to a wide range of human resources with skill sets in all fields including mechanical, electrical, service and spare parts. System integrators may not have access to as broad of a range of human resources to solve any issues in a timely and efficient manner. These combined resources can be a very powerful tool during the integration/startup process."

End User Opinions

Essar Steel India in Gujarat, India, has used a wide variety of options when installing machines, making them well qualified to speak on the subject. Anil Sharma, general manager, explains, "When Essar builds new or adds to a production or packaging line, we've used all three methods—in-house expertise, an OEM and a system integrator or engineering firm. It depends on the project. If it's a big project, an OEM contributes 90%, while the rest is contributed by in-house expertise and a system integrator. For very small systems, a local system integrator or engineering firm is used."

While Essar uses in-house support when it can, Sharma realizes the advantages and drawbacks of this approach. "If the company uses in-house expertise, there is the advantage of low cost," he says. "Employee knowledge increases, they remain technically updated, and it boosts employee confidence and morale. On the other hand, if we use in-house expertise, there are disadvantages. Many times updated technology may not be adopted, the design may not be proper, it may take longer for implementation, and full technical support may not be there."

Essar definitely leans toward using OEMs for integration in most cases, primarily because of their technical knowledge, but it also uses local system integrators when it can, particularly for smaller projects.

Logical Choice

The decision to use an OEM or an SI can be easy. If it's a simple job involving one machine and some auxiliary equipment, the machine OEM is probably the best choice. The OEM has probably installed dozens if not hundreds of similar systems, giving them economies of scale and the benefit of extensive experience. When projects get complex, involving high-level ERP software, multiple production lines and dozens of different machines and control systems, then a system integrator is probably the best choice. This is particularly true when the integrator is located nearby and local support will be needed long after the project is completed. In many cases, existing relationships with OEMs and system integrators will drive the decision, with the plant owner picking the partner with whom they have the greatest familiarity and trust.

AAA Absolute Automation and Electrical Services, a system integrator in Covington, Georgia, offers services for custom machines and production lines, typically using AutomationDirect products whenever possible to create a supervisory level control system to tie all the machines together.

"We've found AutomationDirect products are priced very competitively, and they've been very reliable," says Bob Swarner, systems engineer at AAA. "Their products are almost always in stock, and we can get them next day with free shipping for all but the smallest orders. We also like the fact that the software for some of their newer products is free, and the software that's not free is very reasonably priced. This is a large advantage over some other manufacturers."

Swarner says his company can start with a set of customer specifications—or just an idea of how they want a new machine or process to work—and then generate a complete set of electrical drawings, fabricate the control panels, install the system, and provide startup support, documentation for the system, and continuing service and support. "Our customer base consists primarily of small to medium sized manufacturing facilities, and we provide system integration services to control machines in integrated production lines."

Swarner says integrators offer several advantages over machine builders. "Typically, machine builders are very familiar with their machines and standard applications for it, but not with the specific production line where it'll be installed," he explains. "Since system integrators normally develop an ongoing relationship with a particular plant, they can be more familiar with the production process and people at a particular plant. This allows us to prevent problems that may arise during commissioning a new machine that's integrated with the rest of the process."

An independent integrator may be able to provide better support and service after the installation. "If an integrator is actively involved in maintaining and upgrading the production process at a plant, they'll generally be more familiar with any changes that take place that can affect the output from a particular machine," he says. Then there's documentation. "A system integrator can provide better documentation for a system," he opines. "Typically, a machine builder will provide good documentation for its machine but many times will not spend time documenting how the machine is integrated into the rest of the process. This can cause major problems down the road, especially if the original people that worked on the machine installation are no longer with the OEM."

Perhaps because of their close relationships with local manufacturers, AAA hasn't competed against machine builders. "We haven't seen machine builders crossing into the system integration territory in plants we service," he points out. "Typically, the machine is ordered with a standard controls package, and we make all changes and interfaces required to integrate it into the production process."