Dan Hebert is senior technical editor for Control, Control Design and Industrial Networking. Email him at [email protected].

Simulating machine, robot and process skid operation in software is the best way to test controller code, device settings and HMI configuration—short of actual connection to the completed system. And in many instances simulation is a more practical alternative to testing on an actual system for a variety of reasons ranging from the ability to prototype to the desire to maintain a safe environment by testing in software first.

1. Faster than testing on actual machine or robot

2. Can be used as a realistic training tool

3. Allows rapid prototyping

4. Can be used when actual system isn’t available

5. Shows when application isn’t feasible

6. Allows simulation of other vendor’s equipment

7. Allows testing of every possible fault

8. Exposes unforeseen issues

9. Doesn’t upset current processes and systems

10. Can directly generate controller code

When the complete machine, robot, skid or system isn't available for test, and sometimes even when it is, simulation can shorten the design cycle, improve performance and greatly reduce startup time. Table 1 lists some of the specific advantages of simulation.

Why Simulate?

Accurpress America in Rapid City, South Dakota, makes hydraulic press brakes and shears for fabricating sheet metal (Figure 1). Allen Guernsey, machine control development specialist at Accurpress, says the machines can be complicated. "Our current version of the PLC for the press brakes can handle 28 axes, and we can link machines together to work in tandem," he says. "Sometimes the press brakes and shears are parts of cells, and in these cases other machines arrive at the customer from different factories, so simulation is the only way to run the machines together prior to startup."

It’s often much safer to simulate new operating regimes before testing them out on high-force machines like this hydraulic press brake.

Simulation has reduced the R&D time. "Being able to watch machine movement in a simulated environment has enabled better PLC code because, in simulations, more fail safes can be tested without risking machine crashes," explains Guernsey. "For example, I can simulate hydraulic cylinder characteristics, introducing errors like a stuck cylinder. So far, I have not run into anything that I could not simulate."

Accurpress uses Beckhoff Automation controllers and TwinCAT automation software. "With TwinCAT, the simulation of machine control is fundamental to the software’s design," says Guernsey. The built-in simulation saves time and cuts cost because it’s not necessary to buy a separate software simulation package, learn how to use it and integrate with the controller and its software.

Robotic machine tending and a robotic assembly process were simulated in this dual robot application. Robotic coordination and interaction, automatic sequence, overall cycle time and machine footprint were verified through simulation.

Dave Perkon, vice president of advanced technology at AeroSpec, a machine builder in Chandler, Arizona, also uses simulation software from robot suppliers. "Most of the top robot suppliers have simulation software," he says. AeroSpec designs and builds a variety of discrete manufacturing equipment, ranging from lean assembly stations to high-speed robotic assembly and handling systems (Figure 2).

"During the concept and quoting stage, simulation software helps keep a project moving in the right direction and keeps the customer engaged as their requirements come to life," notes Perkon. "If the actual equipment doesn’t meet the simulation results, it indicates the program needs more work."

And, once the system is designed, some simulators create code. "Although there are configuration differences, the end product from many of these simulation packages are directly downloadable software programming to the robot," Perkon explains.

Also Read: System Design Tools Make Simulation Real

Software Simulation for Safety

Phoenix Contact offers SafeConf safety configuration software that allows hardware simulation direct from the programming software. "When designing automation, it’s important to ensure the functionality of safety systems, most notably on machine startup and validation," says Zachary Stank, product marketing specialist. "Simulation allows you to walk through the startup process step by step before hardware is engaged to ensure all safety logic is functioning properly."

CMD in Appleton, Wisconsin, manufactures high-performance converting equipment for the blown-film and flexible package converting industry. Its equipment includes high-speed rotary drawtape trash bag lines, pre-made pouch equipment, film and bag winders, and end-of-line packaging automation.

"We typically integrate Yamaha robotics into our automation cells," says Chris White, engineering project manager for automation for CMD, which was evaluating a project that would require sorting of different products coming into a single robotic cell. The different products arrive at the automation system in random patterns, random orientation and variable rates. The equipment supplying the product also ran at different cycle rates.

"We needed to determine if we could meet the maximum cycle rate of both lines feeding into the automation system, with extra capacity to handle surges or manually introduced products," White explains. "We worked with Neff Engineering and Yamaha Robotics to accomplish this. We started by explaining expected rates of the lines feeding the automation; incoming conveying speeds; pick window for the robot; drop locations of the various products and the type of end-of-arm tooling for the robot. We agreed that an actual simulation would be the best method for determining the max cycle rates."

White sent drawings, diagrams and other information to Yamaha Robotics, and engineers at Yamaha set up a simulation in the test lab. The simulation was done with an actual Yamaha robot, controller and software. Once a simulation was up and running, CMD sent an electrical engineer to spend time with them, and CMD and Yamaha engineers worked together to fine-tune the system.

"The program routine was written to model the moves required," says White. "We simulated delays for gripper actuation, product settling and any other process delays that might happen in a real-world environment."

CMD learns how the simulation is being performed, asks questions, learns software techniques involved, provides feedback on where the simulation may have shortcomings, adjusts for any shortcomings and determines how to optimize the system further. Yamaha engineers improve their knowledge of CMD’s processes, learn new applications and use this information for future product improvements.

Simulation saves CMD time and money. "Off-line simulation allows us to confirm the system can meet certain requirements prior to designing the integration," White explains. "This reduces modifications that may be required once the machine is in the build and test phases. It reduces lead times and costs because we know the system will work before designing it. We also determine any changes required to optimize the equipment."

Richard Clark, third-party product support engineer at InduSoft, explains how its customers use HMI software simulation capabilities. "It’s common practice for machine builders using InduSoft Web Studio to create a simulated environment to approximate the actual process or machinery. The advantages of creating a process control or machine simulation is implementation in a safe environment without exposing workers to safety-related issues. It also doesn’t expose the production lines to potential disruptions or contamination while new technology is being introduced."

1. Often difficult to precisely simulate operation

2. Safety systems may have to be tested on live equipment

3. Simulations may not be totally accurate

4. Simulations can fail unexpectedly

5. Requires learning of simulation software program

6. Simulation software must be integrated with controller

Challenges and Issues

Although simulation provides many benefits, it’s not without challenges (Table 2). Simulation packages aren’t perfect. "One of the most common challenges I’ve come across with various simulation packages is the simulation shutting down if there are any errors," says Tim Malyszko, director of operations at Malisko Engineering, a system integrator in St. Louis. "In other words, if a simulated device points to a tag that does not exist in the physical or simulated controller, the whole simulation dies." You also have to know your tools. "Simulation software isn’t very intuitive to use and requires a substantial learning curve," he adds.

Simulations aren’t always accurate. "There have been times when our actual robotic equipment did not meet the simulated robot cycle time," notes AeroSpec’s Perkon. "Adjustments to the robot motion profile, and adjusting approach and departure motion profiles, are usually required in the real world. Simulation doesn’t clearly duplicate the real world perfectly."

InduSoft’s Clark agrees. "The main challenges in creating or using simulated environments is accurately modeling and reproducing the operating conditions where the process, machine or robot will be finally integrated."

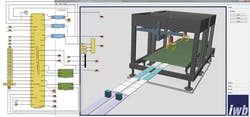

Research is being conducted on innovative methods to master the complexity of machine control at the Institute for Machine Tools and Industrial Management at the Technische Universität München in Munich, Germany. Work was done on the Robobox system, a machine developed by Krones. Researchers use simulation and modeling to design and test algorithms to optimize the control of a packaging and palletizing station.

In the Robobox, the grouping station takes a continuous stream of containers and groups them together in a pallet format specified by the customer. One of the biggest challenges during this process is making sure the flow of materials is consistently supplied.

Synchronizing several kinematic movements while handling various fluctuating material flow conditions exerts enormous demands on the control technology. For this reason, new control concepts are being developed for the Robobox to improve its overall timing with regard to incoming materials. The quality of these new concepts is then checked in advance through the use of various simulation methods.

One approach is known as virtual commissioning. In this process, system control functions are tested in a simulation model at the same time as the mechanical and electrical functions. The Technische Universität München integrates physics-based simulation directly into the virtual commissioning process.

In addition to containing the necessary geometric data, the physics-based model also includes information such as mass, center of gravity and friction coefficients to map the physical behavior of a particular component.

In addition to providing better simulation results, physics-based methods quickly and easily produce models. In this process, the actual design data is converted into a physical model that can be calculated in real time. The geometric model produced from 3D CAD data is used to create a collision model that can be migrated into a physical model.

To achieve a simulation that can be executed, the final step integrates the physical model into the simulation environment. The system model is then transferred directly to the controller as a "hardware in the loop" model. During this process, the simulation models, actual control components and the development environments are linked together via PowerLink.

Automatic code generation provided by Automation Studio Target for Simulink from B&R Automation combines the simulation with the control environment. The controller code generated is integrated into the control project along with the necessary program libraries. This allows the system model and functions to be transferred to the development process without excess effort.

Bill Savela, marketing director for Delta Computer Systems, sums it up. "A simulator must provide results that are true to the actual hardware," he says. "While simulation can provide valuable information prior to installation, it’s not the real system. Tasks like final tuning, verifying sequence of operation and ringing out wiring are still required."

Conclusion

Simulations are becoming a major part of control system development. Many vendors, such as robot manufacturers and control software suppliers ,are building simulation capabilities into their systems because they realize the value it provides. As Daymon Thompson, TwinCAT product specialist at Beckhoff puts it, "Software and hardware suppliers in the automation industry are aware of the advantages and the power of simulation, and embrace it as core to machine design."

Sandia National Laboratories studies the effects of various fuels used in diesel engines in the Alternative Fuels Laboratory located at the Combustion Research Facility in Livermore, California. The lab analyzes the combustion of many different fuel types, and tuning the fuel control and monitoring system for differences in the fuel’s viscosity and compressibility was taking too much time, so Sandia turned to off-line automation system simulation. Samuel Fairbanks, R&D laboratory support technologist, is now able to simulate the system before a test and make appropriate tuning changes ahead of time.

"Simulating the operation of our high-pressure fuel system using MathCAD allows me to verify hardware requirements for mechanical design of our high-pressure fuel system," says Fairbanks. "It also aids in tuning the system for different fuels by allowing me to adjust PID coefficients in the model, making it possible to get very close to the actual values needed. Being able to tune the system more quickly also reduces component wear, which is accelerated at high pressures."

The high-pressure fuel system consists of two diaphragm pumps each driven by a hydraulic cylinder. These are controlled using feedback from SSI position transducers using a Delta Computer Systems control system with dual-axis and other I/O modules. The control system modulates hydraulic flow to the cylinders via proportional control valves.

"Multiple pressure transducers for each pump monitor oil and fuel pressure, and discrete signal inputs adjust system gains on the fly based on changes during operation," explains Fairbanks. "All of the I/O modules are connected to a Delta RMC75E motion controller, and the controller is in turn networked via Ethernet to a PC running a custom Python program that monitors and controls many other systems in our laboratory."

Each pump has a cascaded PID control loop controlling the fuel pressure by adjusting the speed of the hydraulic cylinder stroke. The PID control loop also keeps oil pressure in the diaphragm pump in check, which can spike if the stroke length is too great or frequency is too high.

"I have to retune parts of the system every time we change fuels," adds Fairbanks. "We are constantly studying different fuels, so this happens frequently. Being able to streamline this process with simulation is a huge benefit."

Sandia uses the RMC simulator from Delta, a built-in function within the RMCTools software used to program the controller. "It simulates the movement of the hydraulic cylinders, driving the diaphragm pumps and their response under pressure conditions I specify," notes Fairbanks. "This is a vital tool, allowing me to see how the system will respond under specific conditions."

Fairbanks can even create hypothetical problems. "I can feed modified pressure data from previous runs and create conditions such as fuel pressure overshoot, oil pressure spikes and others to see if the control program I wrote makes the cylinders respond correctly," he says. "It's a very useful way to test the logic of the program, and I’ve continued to use the simulator while trying to optimize the programming or add new functionality."

While the simulator works well, it wasn’t easy to set up. "Our high-pressure fuel system is extremely complex, which made creating a numerical simulation as realistic and accurate as possible both tedious and time consuming," explains Fairbanks. "It can be difficult to accurately model some of the interactions between hardware and fluid components during our extreme operating conditions."

It took a little over a month to build the model, and the major issues were trying to accurately simulate interactions between hardware and the fluids, both oil and fuel. "In the end, we were able to create a simulation that captured all aspects of final system implementation," says Fairbanks.

As for future improvements, "Providing more user-friendly tools to record data during system operation, and ways to interface this data with simulation tools to make adjustments or corrections in a simulation to use during further development, would be invaluable," concludes Fairbanks.

But simulation is not quite a walk in the park. Setting one up can be difficult. And if the simulation isn’t a very close match to a real system, it won’t be very useful.

Despite these difficulties, simulation benefits outweigh the challenges in many applications, particularly those where testing on live equipment isn’t feasible, safe or convenient.

About the Author

Leaders relevant to this article: