Once a machine is designed, built and tested, it enters the operation phase. But, before production starts, plant managers, reliability engineers, maintenance managers and technicians want to be involved. They’re thinking ahead to the maintenance and reliability portion of the equipment's lifecycle.

Close partnering with an original equipment manufacturer (OEM) or custom machine builder should be in the plans, as well, and artificial intelligence (AI) may also be part of the discussion.

Some may just embrace the latest technology and think it provides a solution needed to reduce maintenance and improved reliability. However, these reductions and improvements start in the design phase of the project, before a machine has even output its first part. It's not just about the technology, best practices in design and quality components will always play a big part in the successful development and operation of a machine.

"Ideally operators would like to be able to load a part, push a button and have a machine pop out a perfect part every time," says Mark Horton, chief engineer, advanced process technology, at Kollmorgen. "The machine would require no changeover, and the tooling would never wear out. Also, they would never have to perform any maintenance. Managers want pretty much the same thing. They want to have a stable process with no unplanned downtime. This makes planning and execution much easier. Since the scenario I’ve presented almost never exists, especially in a low-volume, high-product-mix environment, much can be done to improve machine reliability and reduce its operational maintenance during the design phase."

Do it right from the start

From the start, the design and components used are critical, but maintenance must be included at the beginning, as well. "From the OEM's perspective, the customers’ general sense of equipment robustness and reliability is a major factor that affects repeat business," says Leon Krzmarzick, director of engineering at Delta Technology in Phoenix. "Attempts to save money by using lower-tier hardware rarely achieve that goal and end up costing everyone involved due to downtime and redesign expenses. Identifying and properly designing wear items are the first steps to providing reliable equipment. Spare parts lists and maintenance schedules help the end user to minimize downtime. In critical applications, we have added vibration and temperature monitoring. These help to indicate possible maintenance issues before complete component failure occurs, saving the machine from major damage."

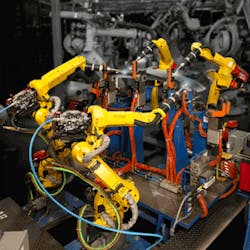

It is also important to put a strong emphasis on designing and building machines that will exceed the end user’s expected product lifecycle. "The best method for achieving a long machine life is utilization of quality, proven and commercially available components within our designs and providing a thorough maintenance manual and schedule," says Dean Colwell, controls manager, assembly, welding and AGV Systems at Fori Automation in Shelby Township, Michigan. "Fori also trains the end usesr during the buyoff and installation phase of the project. This is important to ensure the maintenance schedule is completed on time and as expected. Completing the preventive maintenance will help to keep the machine up and running for its expected life (Figure 1)."

Figure 1: A good design and easy maintenance helps to keep a machine running.

(Source: Fori Automation)

In recent years, it seems equipment customers are performing less scheduled maintenance than in past years, says Doug Putnam-Pite, director of software development at Owens Design in Fremont, California. "It therefore behooves us as tool designers to develop robust tool designs that can work for extended periods of time without routine maintenance," he says. "Additionally we need to ensure that the software in the tools can detect errors and fail in a safe state without damaging the mechanisms in the tool."

Smarter machines that can monitor, diagnose and communicate developing issues are enabled by starting with newer architectures using Ethernet and Internet protocols for communication to smart I/O blocks and devices. "The overall equipment effectiveness (OEE) of a machine and production line is impacted by how data is efficiently collected and communicated, which often means more design time up front on network infrastructure selection," says Dan McGrath, product manager at Panduit, a member of the Control System Integrators Association (CSIA). "However, it can pay dividends over the lifetime of the machine.” New wireless sensing architectures that communicate using machine-level protocols, such as EtherNet/IP, and can plug into the Industrial Internet of Things (IIoT) for monitoring equipment health should be considered at the design phase to capture data at a lower cost point and simplify deployment.

Find a strategy

"From a service perspective, we’ve worked with customers who are struggling to find the right strategy for maintaining the existing fleet of machines and knowing when to invest in new ones,” says Joseph Kernich, consulting application engineer, certified reliability leader (CRL), at Siemens. "Many address service and maintenance on a reactive basis—waiting until faults occur. There are obvious pitfalls in this strategy, everything from lost production to expensive, emergency repairs."

This has led many companies to look to change from a reactive to a proactive approach to maintenance management. "Knowing how to get there, however, can be a challenge. In many cases, the time and effort of creating a proactive maintenance strategy on their own becomes an impediment," says Kernich. "In the end, actual results don’t meet the expected gains. For planners, the promises of improved machine uptime create the anticipation of production ramp-up. When the opportunities aren’t realized, this creates a lot of frustration, not to mention questions about the time and resources spent pursuing the unmet goals which ultimately impact the bottom line."

The combined knowledge of an OEM as a machine tool builder and the end customer using the machine tool every day is the key to succeed in this proactive approach, says Kernich.

"It may be basic to say that a broken machine can’t make parts, but oftentimes the fight that maintenance has to deal with is its own plant management," says Daniel Moore, tech support manager, Universal Robots. "Whether you’re talking about robotics or my past life in laser welding systems and automatic monitoring systems, if there’s a cause for repair, then you basically have two options: Do it right, carefully and slowly the first time, or guarantee another, worse failure."

Pressure on plants to produce parts right now often means that there is pressure to not do it right and leave the failure to another shift or another week, continues Moore. "Ultimately this is a horrible idea for any company, but it’s often the kind of thing I saw working on laser systems in automotive suppliers or in the auto shops themselves," he explains.

Effects on the bottom line

"A best-practices design approach needs to be taken when specifying components in automation control panels, so that the selected parts are not operated at or near their design limits," says David Paul, engineering design manager at Maverick Technologies a member of CSIA, headquartered in Columbia, Illinois. "There are also best-practices design choices to include surge suppressors, electrical filters and other similar devices in control panel design. While these devices can potentially increase up-front machine costs, there is a long-term payback in reduced maintenance and component failures."

Figure 2: When making best-practice machine-design choices, carefully weigh the tradeoffs between CapEx and OpEx budgeting.

(Source: Maverick Technologies)

Unfortunately, due to the highly technical nature of these added components, many purchasing decisions are made solely on a machine-cost basis, continues Paul. "This is the tradeoff that occurs between capital expenses (CapEx) and operating expenses (OpEx) budgeting within many companies," he says (Figure 2). "During projects, many times the corporate-level project team is focused on staying within a CapEx budget but not so concerned with long-term OpEx costs. Operations teams are much more focused on OpEx costs because of their role in day-to-day plant operations and maintenance. Some companies now involve plant operations in CapEx equipment selection, which is a best practice to assure minimal long-term maintenance is required."

Two interdependent lifecycles need consideration during the design phase. “The first is the process lifecycle—how you create value by turning raw material into a finished product," says Joseph McMullen, technical support, product management and marketing, at Aveva Group. "The second is the asset lifecycle, concerned with the health of the equipment that is used in the process to make the finished product. The design phase must take both lifecycles into account."

A process can be optimized to create the most value while running. "However, if the assets in use fail because maintenance schedules were not being considered, then the extra value from optimization is lost due to downtime from failed equipment," says McMullen. "Alternatively, an asset can be meticulously maintained to extend its life, but, if it is done at the expense of shutting down operations, then you have the same problem of lost value."

Figure 3: Proper maintenance of cables, sensors, mechanical drive components, electronic hardware, calibration and grease is critical to keep the machine functioning properly.

(Source: Fanuc)

The right approach is to consider both lifecycles. "You need to think strategically about maintaining your asset. One way to do this is with predictive maintenance that will allow you to anticipate problems before they happen. This will give you the option of being more strategic when deciding to go off-line for maintenance activities."

A typical robot machine is designed to achieve more than eight to 10 years of life with proper maintenance, says Jason Tsai, vice president, product development, at Fanuc. "Maintenance items can include cable, sensors, mechanical drive components, electronic hardware, calibration and grease," he says. "Proper maintenance is critical to keep the machine functioning properly and avoid any premature component failure. For a high-throughput production factory, any machine breakdown could cause significant production downtime and profit loss, which can impact the business’ bottom line (Figure 3)."

Product reliability is a must-have requirement in production factories with robot automation, continues Tsai. "If the machine is designed poorly with low product reliability or safety design margin, the machine breakdown can cause production downtime and significant profit loss,” he says. "Therefore, proper maintenance and high product reliability are absolutely critical to maintain high production throughput and increase profitability."

Wants and needs

"Managers and operators alike want a low-maintenance and highly reliable machine," says Krzmarzick at Delta Technology. "What do they want, and how can machine reliability be improved during the design phase? Simply put, end users want equipment that works."

Generally, customers are interested in which items and procedures are needed for preventive maintenance. "In particular, many ask about lubrication points and frequency of replacement for wear items," says Mike Krummey, electrical engineering manager at Matrix, a ProMach brand, in Saukville, Wisconsin. "Since the beginning, Matrix focused on designing our machines with ease of cleanability. This allows for a more sanitary operating machine and one that is inherently more reliable as the preventive-maintenance procedures are very simple and fast to perform. If these things are too difficult and time-consuming, there will be a higher likelihood of those procedures being ignored and not performed."

Roger Beam, principal engineer at Optimation, a member of CSIA, in Rush, New York, provides a list of best practices of interest to managers and operators when it comes to machine maintenance including:

-

maximize mean time between failure

-

minimize time to repair

-

maximize overall equipment effectiveness by minimizing unscheduled downtime

-

provide easy access to equipment requiring frequent adjustment, inspection and/or replacement and points of lubrication

-

provide or accommodate means of lifting heavy components

-

provide components sized for continuous 24/7 duty cycle with a service factor of safety

-

design guarding for easy removal and installation.

Reduce maintenance

"Machine reliability can be increased during the design phase if all the end-product requirements are well-defined," says Chris Villareal, senior mechanical design engineer at Delta Technology. "For example, take a press application. If the customer knows how much force is required to assemble the product, the machine design team can easily provide a robust solution with headroom to handle part variation. Many sample parts are often needed to ensure the design limits are understood and suitable headroom is available for part variations."

Cycle time is another area that gets overlooked but should be carefully reviewed and locked down during design. "Having realistic expectations for part throughput is often overridden by a desire to get the ROI on a piece of automation down to a shorter time period," says Villareal. "While some parts are well suited for high-speed automation, the opposite is also true. Sometimes small reductions in cycle time can be challenging."

Decreasing a cycle time of a machine sequence from 2.5 seconds to less than 2 seconds, part to part, can expose an exponential series of challenges to solve, continues Villareal. "On paper, this looks simple," he says. "In reality, it may require a complete re-thinking of the machine to make it automation-friendly, which may also include more expensive actuators and faster controls hardware to achieve the desired cycle time in a reliable manner."

Machine-maintenance needs during operation is really a question of robustness. "Marginal solutions may work well for a while, but over time, the deficiencies of subpar or undersized components may start to show," says Krzmarzick. "Broken shocks, worn bearings, a weak support structure and other frail components eventually cause loss of adjustment. Once the machine is in this state, maintenance costs escalate. With proper design, these issues are minimized."

A good design is often quick to repair. "Providing a modular design enables sub-assemblies already assembled or aligned to be swapped out to minimize machine downtime for repair," says Optimation’s Beam. "To help achieve this, have a design review with the customer, including maintenance personnel, of the machine's 3D conceptual model prior to detailed design or fabrication for the feedback and acceptance."

Control systems and maintenance

"At Matrix, our control systems follow the same design intent as the mechanical componentry—simple is inherently more reliable," says Krummey. "If many complicated components and dependencies are present on a machine, there is a greater chance of increased downtime. Control-system reliability is also a function of the number of machine sensors. The fewer sensors, the more reliable the system will be, as you can’t have downtime for a damaged sensor that isn’t on the machine. Control programs can be developed that reduce the number of sensors and thus increase reliability and continuous uptime."

Predictive maintenance is perhaps the most important consideration. "Machine-health monitoring is one of the benefits of IIoT, but there's no reason to wait for that," says John Kowal, director, business development, at B&R Industrial Automation. "We all know that motors can provide valuable information to warn of mechanical wear. Not enough users specify condition monitoring of key mechanical components, most commonly frequency changes in critical bearings. The small added cost is well worth the investment."

Machine builders can improve reliability by eliminating nuisance faults that are caused by human or program errors and reducing the number of mechanical and electrical parts, says Mike Wagner, global OEM packaging lead at Rockwell Automation (www.rockwellautomation.com). "They can also reduce inertial mass to decrease mechanical stress and reduce vibration," he says. "Additionally, machine builders can use direct-drive technologies, adaptive tuning, adaptive notch filters and simulation design tools to start improving the reliability of their machines."

Control systems that involve a PLC with IIoT capability can significantly reduce machine downtime and increase reliability. "A PLC with IIoT acts as a bridge between the existing operational technology within a plant and plant database networks, so valuable data can be shared reliably and securely to improve plant productivity and efficiency,” says Vaidhyanath “Doc” Nanjundaiah, director, marketing and customer success at AVG Automation. "It helps in predictive maintenance, and it’s an innovative way to track and analyze equipment. A PLC equipped with IIoT capability helps to be proactive, not reactive, by sending the real-time data to the maintenance department. Predictive maintenance in a nut shell increases plant productivity by 25%, reduces costs by 30% and reduces downtime by 45%. Due to these and other benefits of IIoT built in to a PLC, all major manufacturing plants are moving to have a plan in place to adapt to this revolution in industrial automation. Implementation costs are low, and payoffs come quickly."

See-and-do maintenance

Figure 4: Availability of information, such as cycle counts, run time and maintenance schedules, ensures maintenance needs are understood and completed within an expected time frame.

(Source: Fori Automation )

"Maintenance information can be integrated into the control system and provided via the operator screens," says Colwell at Fori Automation. "Information such as cycle counts, run time and maintenance schedules can be made available, which will help to ensure that preventive maintenance is completed within the expected time frame. Additional maintenance information of this sort can be pushed to a MES and other maintenance databases and dashboards (Figure 4)."

The HMI provided needs to be easy to use and intuitive to operate. "Our customers’ preferences have been for tools that can be used directly by their operations and process engineers on-site," says Sanket Amberkar, senior vice president of marketing at Falkonry. "Even the machine-learning system needs to be ready to be used by them both in terms of developing the learning models and providing warnings and actionable insights back to them to take prescriptive action. The alerts and interface should be accessible through the existing dashboards or portable devices used by the operations team and should not add an additional screen to be monitored and managed."

Picking components that allow the usage of the latest technologies, such as augmented reality (AR), can dramatically improve the efficiency of the maintenance process, says Simone Gianotti, EcoStruxure industry business development manager at Schneider Electric (www.schneider-electric.us). "In cases where leveraging AR is not a possibility, the design phase should at least include the development of easy and thorough HMI screens to simplify the research of manuals, schematics and how-to documents," he says.

Unlike computers, machines and robots deal with the real world. "They answer to the laws of physics, but they can’t communicate that easily," says Sam Bouchard, CEO, Robotiq. "An interface, whether it’s on a machine, in a robot teach pendant or coming from a monitoring software, allows us to know more about what’s going on with the equipment and taking the right actions to prevent problems and of course to improve production."

AI in time

"Artificial intelligence (AI) is a very cutting-edge technology, especially for an industry that is slow to adapt new technologies," says Putnam-Pite of Owens Design. "At this time, I would image that most of the AI initiatives for machine tools will take place on the production-floor side of the world. We have not had customers asking us to implement AI platforms to improve machine maintenance and reliability. I would also think, given the expense of these implementations, that the cost would be prohibitive except for a few key industries."

Artificial intelligence can allow OEMs to guide the troubleshooting process with access to the data on many machines. "Perfection of AI reliability scenarios requires machinery in a wide variety of applications, so as not to make incorrect assumptions," says Matrix’s Krummey. "Our machinery has a very large installed operating base across every part of the packaging industry. This application experience has resulted in machinery that can perform at optimum levels with minimum cost and complication."

Artificial intelligence can play a vital role in any maintenance and reliability program. "The systems and tools available now allow predictive maintenance programs to substantially reduce downtime," says Justin Olivier, product manager, Mobility, at Pepperl+Fuchs. "However, it is important to make sure that workers in the field are equipped with tools that allow them to be connected to those Industry 4.0 systems. Not only does this allow them to monitor systems in real time, but it also makes sure that any maintenance performed is accurately recorded and helps to close the loop so that all parts of the system can work together for peak efficiency. Other related technologies, such as augmented reality, can also help to simplify and shorten training time for new employees (Figure 5)."

Figure 5: Connections to the IIoT, monitoring systems, training and augmented reality will all be a common part of AI.

(Source: Schneider Electric)

Artificial intelligence can improve the maintenance and reliability of a machine through preventive and predictive maintenance, says Gianotti at Schneider Electric. "The world of industrial automation is not quite there yet, but the vision is to have AI that can identify not only trends to provide predictive maintenance, but also identify where the machine can be improved, for example, through analysis of energy and current consumption," he says. "A self-teaching machine that constantly calculates trends and adapts design and operations to improve efficiency is no longer science fiction, but a clear direction the market is aiming toward."