Optical encoders

Figure 1: Optical encoders contain marked code discs. The greater the density of the markings, the higher the resolution of the encoder.

The automation industry relies on encoders to provide high performance and sophisticated capabilities. Incorporating a feedback encoder into a motion control system allows a higher level of system performance. Automated processes differ from one another and therefore require a variety of different encoder options. Selecting the proper encoder for your unique system is essential to gain effective feedback data. Before choosing an encoder, you’ll want to understand more about how resolution, accuracy and repeatability affect system performance.

Encoder resolution

Encoder resolution is the number of measuring segments or units in one revolution of an encoder shaft or 1 in/mm of linear scale. Typically, we measure encoder resolution in pulses per revolution (ppr) for incremental encoders and bits for absolute encoders.

An encoder pulse refers to the smallest segment of a given angle or length that the encoder can measure or discern as a movement. One can think of it as minute marks around the edge of a clock face. On an optical encoder disk, the more densely scribed the pattern, like adding more minute marks to the front of a clock, the higher the resolution (Figure 1).

Rotary encoders are readily available with resolutions of up to 10,000 pulses per revolution (ppr) directly and 40,000 PPR via interpolation. Linear scales offer resolutions on the order of microns. Higher resolutions can be obtained at a higher cost but a decrease in lifetime reliability. The most common resolution for industrial controls is 1,024 pulses per revolution.

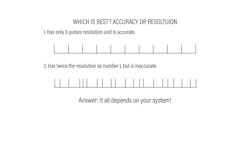

A common misunderstanding regarding encoders is the assumption that the best encoder has the highest resolution. This idea is overly simplistic and can lead to severe implications with your machines. One cannot assume that a higher encoder resolution improves the accuracy of the whole system. Increasing resolutions will not compensate for some types of system errors. With the addition of more pulses per revolution, the encoder's ability to report position may improve. However, if there is a systematic error, a higher resolution will not correct it and may confuse the issue instead. Figure 2 shows how accuracy and resolution differ, driving home the fact that high resolution does not always result in better accuracy.

Figure 2: Increasing resolutions will not compensate for some types of system errors.

Encoder accuracy

Encoder accuracy accounts for the difference between the value readout by the encoder and the physical angle in real life. Encoder accuracy is measured in a fraction or degree, like arcminutes or arcseconds. For example, 20 arcminutes (0.33°) or better is considered a moderate-accuracy encoder. Whereas, some precision devices are on the order of 5 arcseconds (0.0014°). Manufacturers also can specify relative accuracies. Incremental encoders commonly have specification of signal duty cycles and phase angles.

Multiple error sources can degrade the accuracy of an encoder reading. One of those sources can be the manufacturing processes of the encoder itself. The widths of the lines on the optical encoder disk will vary, however small that variation may be. A discrepancy in the exact centering of the encoder disk could introduce a small error in the timing of the pulses generated by the encoder. Manufacturers go to great lengths to minimize or eliminate each of these errors. Sometimes, manufacturers will use an external, high-precision, scientific-grade encoder as a reference to measure the amount of error of the sample encoder. The sample encoder can then be fine-tuned and recalibrated to improve accuracy. It is reasonable to ask, “If a high-accuracy encoder is available, why not use that one?” Encoders with higher accuracies and higher resolutions are also higher in cost, are less rugged and have shorter lifespans.

In other instances, external errors can stem from the equipment or machine itself. For example, a gearbox might have backlash, or a lead screw might have played in its motion. Flexible couplings have a windup, while metal frames or suspension cables can grow and shrink according to temperature. Commonly, errors due to external factors are much more significant than even a “low” accuracy encoder. It is essential to keep in mind that, as a sensor, an encoder can only report on the position of the equipment it is monitoring. The controller must accommodate all error corrections.

[javascriptSnippet ]

System repeatability and encoders

What is encoder accuracy without the additional characteristic of repeatability? Repeatability is a measure of how consistently the system can return to the same commanded position, time after time. For encoders, repeatability would typically be two to 10 times better than absolute accuracy. Encoder repeatability reveals the encoder’s likelihood to be consistent in its accuracies, as well as inaccuracies.

A pulse is considered repeatable if it registers a pulse as slightly longer than the rest and continues to detect it as the same longer angle on every revolution. When the encoder has excellent repeatability, many errors can be averaged out or corrected in the system controller. Many applications, such as classic velocity control (variable speed motors), function quite well with lower-accuracy, but repeatable encoders.

Figure 3 illustrates three different scenarios of repeatability in relation to accuracy. The first example simply shows an accurate pulse with an even pattern. Below that, is the first set of rotations where an inaccurate but repeatable pulse is demonstrated. This is considered good performance because the encoder can account for the inaccuracy with repeatability. The second set of rotations shows an inaccurate and nonrepeatable pulse, which is not ideal.

Figure 3: This illustrates three different scenarios of repeatability in relation to accuracy.

Like with absolute accuracy, external sources are accountable for errors in repeatability. The manufacturing process of the encoder, the equipment being positioned and even the sensing technology employed can contribute to errors in repeatability. Certain types of encoders, such as analog tachometers or some versions of capacitive encoders, can suffer from cumulative errors that build up over multiple cycles. These are the exception rather than the rule. Optical and magnetic encoders are designed to prevent cumulative errors. In general, optical encoders have higher overall accuracies than magnetic-based units. Why are magnetic systems so popular? They tend to be far more rugged and reliable and have greater mounting flexibility and mechanical structure.

Like absolute accuracy, mechanical errors such as gearing backlash, hysteresis and improperly tensioned belts can reduce system repeatability. As with resolution, users frequently assume that buying an encoder with high repeatability will give the best results. Even an encoder with excellent repeatability cannot improve on a system with poor mechanical reproducibility. A highly repeatable, yet inaccurate system—mechanical and encoder combined—can often achieve completely acceptable performance levels if the errors are understood and corrected.

Encoders can be a powerful element in a motion control system. The system designer should consider the pros and cons of various encoder options that are available. Understanding the sources of the errors can lead to better system performance and ease troubleshooting, should a problem occur.