Bill Dehner has spent the majority of his 15-year engineering career designing and installing industrial control systems for the oil and gas, power and package-handling industries. He holds a bachelor’s degree in electrical engineering with an associate’s degree in avionics from the U.S. Air Force and is currently working for AutomationDirect as an automation specialist.

Tell us about your company’s state-of-the-art industrial-networking technology.

Bill Dehner, automation specialist, AutomationDirect: Consumer technology always has a way of affecting the industrial realm, as the technology that we use in our personal lives naturally drifts into our professional lives as well. The IIoT—and cloud connectivity in general—is a perfect example of this. Industrial cloud networks have become popular and our StrideLinx secure remote access solution allows users to cloud-connect any machine or system for a very attractive price. StrideLinx VPN routers use an outbound connection to the StrideLinx cloud platform providing both a secure connection to remote systems and machine data storage that can accessed anytime from anywhere.

What have been the biggest improvements to industrial-networking technology in the past five years?

Bill Dehner, automation specialist, AutomationDirect: The convergence of IT and OT network topologies. Opening up the wealth of data collected on a daily, even hourly, basis from plant floor machines to upper-level planning and management systems by merging IT and OT network topologies has improved operational efficiency and preparedness across many industries. As more industries realize the potential benefits of IT and OT merging, it will become incumbent for plant floor components to offer the needed IT-friendly networking protocols to facilitate high-level analysis of production data.

What’s the most innovative or efficient industrial-networking technology application you’ve ever seen or been involved with?

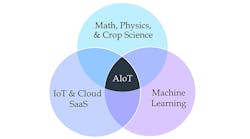

Bill Dehner, automation specialist, AutomationDirect: Recently our engineering group demonstrated how the embedded Rest API and JSON instructions in our BRX PLC could be used with cloud services (IBM Watson), data flow applications (Node-Red) and the Google Assistant app to control a delta robot using only voice commands. Modern PLCs, like the BRX, are now offering advanced networking solutions that enable some very innovative IIoT type applications (Figure 1).

How has industrial-networking technology benefitted from remote monitoring and connectivity?

Bill Dehner, automation specialist, AutomationDirect: Remote monitoring and connectivity involve an inherent security risk, so the increasing adoption of these technologies is also prompting greater scrutiny into the security aspects. To combat any possible vulnerabilities, securing networks and connected devices has taken center stage. Today’s industrial networks and associated devices are more secure than ever with numerous countermeasures employed to keep systems safe from intrusion. Improvements in the way we secure remote access to industrial networks/devices has been a benefit and a direct result of opening up internal networks to external users.