Where exactly is the network edge?

Smart machines and smart manufacturing in general are not new concepts to industrial control designers. Typified by their use of microprocessor-based control, data acquisition, diagnostics, analytical and similar hardware and software, smart machines exploit these technologies to enable business value propositions in areas such as reduced machine downtime, production flexibility, asset management and remote access, among others.

The recent advent of Internet-enabled business-improvement strategies, such as the Industrial Internet of Things (IIoT), Industry 4.0 (I4.0), IT/OT/ET convergence and others has led to a heightened focus on the industrial network edge and the machines and devices that populate it. Remote machine access for monitoring and service, along with increased adoption of analytics, cloud-based applications, and big data to improve production performance, are primary initiatives currently pursued to address these and similar business requirements. Internet-enabled strategies hold promise for even further innovations in areas such as machine-as-a-service where customers subscribe to outcomes rather than purchase machines and equipment outright.

Why have these developments led to increased focus on the industrial network edge and associated devices? Because the edge is where the assets to be optimized and the associated data to be analyzed by enterprise applications reside. This results in continual demands on machines and other edge devices to “feed the beast” of enterprise applications. This emphasis on communication with enterprise and other higher-level applications is partially behind the use of the term “network edge,” since a top-down perspective from the enterprise level results in machines and other production equipment appearing at the outer edge of the architecture.

For the purposes of this discussion, the industrial network edge includes end devices such as machinery, other assets and associated end devices, such as controllers, sensors and HMIs. It also includes edge infrastructure devices such as Ethernet, wireless and cellular gateways; Ethernet switches and routers; and wireless access points (WAPs) used to control, manage, isolate and enable higher-level access to smart machines and other field or device level data sources. While automated machines, controllers, sensors and similar equipment have been in use for decades, the computation associated with their activity has traditionally been the realm of dedicated logic, motion and/or process (loop) control.

ALSO READ: New technology pushes machine smarts to the edge

The control architectures associated with these applications have similarly comprised dedicated control processors and systems characterized by use of proprietary operating systems, vendor-specific programming languages and dedicated control networks.

Adoption of an industrial network edge perspective in the context of the IIoT and I4.0 necessitates expansion of the smart manufacturing vision in key areas such as data management, application rationalization, operating platforms, communication networks and holistic and endpoint security.

Migration of controllers, HMIs and other automation and infrastructure equipment toward use of standard microprocessors, commercial-off-the-shelf (COTS) operating systems (in particular Linux) and industrial Ethernet networks was already underway prior to the rise of Internet-enabled business strategies, but these developments are further enabling the vision of the role of the network edge in Internet-enabled strategies.

This is true not only from the perspective of the ability to seamlessly communicate between the edge and the enterprise, but also the question as to what functions the edge is capable of performing given these new platforms, capabilities and data requirements.

The sheer volume of data generated by production devices drives the need for data conditioning at the edge, including in the form of anomaly reporting or other structured feeds, in order to prevent enterprise applications from choking on the data deluge from the field. It also raises the prospect of industrial network edge and infrastructure devices acting as field extensions of enterprise applications in one iteration of what is now known as edge or fog computing.

From our perspective the push toward edge or fog computing differs from traditional distributed automation, in that it represents machine or edge-level execution of application components traditionally associated with enterprise applications rather than distributed control. Edge analytics residing on microprocessor-based machine or infrastructure components are currently the most prominent example of this scenario, but edge computing and the choice of what to execute where in the architecture gives designers and implementers more options in overall system design. It also allows machine builders and their customers the option to keep some tasks at the machine level in service of latency, security and other requirements.

Concurrent with the emphasis on the role of the network edge in industrial Internet-enabled architectures is the choice of how to enable integration with the enterprise architecture, in particular with cloud-based solutions.

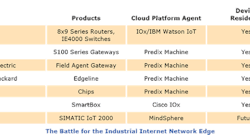

Several standard protocols, such as MQTT and AMQP, have emerged as tool-based options for data integration. We also anticipate the battle of the Internet platforms to ex-tend to the industrial edge, with heavyweights such as General Electric (Predix) and the IBM (Watson IoT)/Cisco (IOx) partnerships bringing their platforms to edge devices via both their own and their partners’ products. One issue for machine builders and their customers in this scenario is whether or not edge-to-cloud integration and adoption of supplier-specific industrial Internet operating platforms will emerge as the next vendor lock on industrial automation systems (Table 1).

Table 1: One issue for machine builders and their customers is whether edge-to-cloud integration and adoption of supplier-specific industrial Internet operating platforms will emerge as the next vendor lock on industrial automation systems.

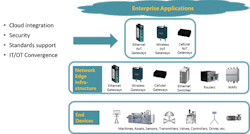

Architecturally these developments are driving an emerging, perhaps interim, approach that relies on industrial edge gateways to perform key functionality in areas such as cloud integration, support of IT integration protocols and security (Figure 1). These IIoT gateways are offered in both embedded (industrial PC) and standalone form factors from the likes of Advantech, Dell, HPE and others. Many of these IIoT-centric gateways incorporate the Intel IoT platform, which includes Intel microprocessors, Linux or Windows 10 operating systems and McAfee security software.

Figure 1: Developments are driving an emerging, perhaps interim, approach that relies on industrial edge gateways to perform key functionality in areas such as cloud integration, support of IT integration protocols and security.

Chantal Polsonetti is vice president at ARC Advisory Group, whose research into the IIoT, industrial network edge and industrial automation provided the basis for this article. Contact her at [email protected].

Sponsored Recommendations

Leaders relevant to this article: