As controllers trend smaller and faster, even those applications without the need for the highest precision equipment are benefitting from this trend in motion control. User-friendly products that integrate and communicate across many platforms are also opening up more control options for a wider market.

Four manufacturers—Nippon Pulse, Hilscher North America and Aerotech and AutomationDirect—offer solutions for customized systems, a one-chip solution, high-precision applications with electromagnetic interference and easy to implement servo systems with control features.

Quick custom control

Faster processors, smaller semiconductors and new firmware development processes are driving smaller and more flexible controllers, says Bob White, technical sales manager at Nippon Pulse.

“The ability to write code so as to simplify the process to customize that code for specific applications is a trend many control manufacturers are facing,” White says. “Customers with innovative process concepts are driving new combinations of functions that optimize machine performance.”

To meet this demand for performance and new concepts, Nippon Pulse introduced the Commander core, a four-axis hybrid IC motion controller, in 2020. This controller bridges the gap between off-the-shelf and design-from-scratch, explains White.

Commander is based on Nippon Pulse’s PCL6045BL ASIC, which uses its PCL6000 series chips (Figure 1). “The PLC6000 is a dedicated ASIC chip focusing on motion-centric operation reacting within two clock pulses, providing ultra-fast motion control capabilities,” White says.

Commander can be used across a variety of market segments and is ideal for applications such as textile machines, CNC milling, welding equipment and small robotics. “Commander was designed for OEMs to be able to scale to high-volume production with minimal design time and support, as engineers can quickly prove out system programs and designs,” White says.

The component itself is about the size of a business card, which makes it easy to integrate into a final printed-circuit-board (PCB) design, White adds.

Shortly following the launch of the Commander core, Nippon Pulse launched development kits, which help with fast prototyping and evaluation. “We wanted to offer an intermediary product that would allow for custom control, but with a shorter design cycle and a cost-effective price point for scaling to higher volumes,” White says.

Time to market has become critical to capturing market share, he adds. The development kits offer everything that’s needed to set up a system and write programs to test machine concepts. “All the effort in writing the initial code is then fully portable and scalable to the production environment,” White says.

“Off-the-shelf motion controllers limit the machine designer to a collection of features that may limit the desired performance or offer features that are not required. A design-from-scratch approach takes development time as well as the right personnel to accomplish the fabrication of PCBs and coding. The Commander core minimizes the effort by the designer to create a motion engine and allows them to focus on the aspects of their machine that will differentiate it in the marketplace,” White says.

Figure 2: Motion-control capabilities were added to the netX 90 multiprotocol network chip, netMotion, combining motion control and real-time communications in a one-chip solution.

One-chip solution

Hilscher’s customers are looking for motion-control systems that are integrated with industrial communications, says Phil Marshall, CEO of Hilscher North America. “While electric motors perform many essential tasks in automation, they need to be fully integrated in the factory network. Typical chip solutions for motion- and motor-control systems often lack real-time Ethernet connectivity. A two-chip solution increases complexity and bill-of-materials costs,” Marshall says.

Hilscher’s one-chip solution, which integrates motion control with real-time communication networks, was launched in late 2020. Hilscher added new motion-control capabilities to its netX 90 multiprotocol network chip, netMotion (Figure 2). “It combines motion control and real-time communications in a one-chip solution. The single-chip solution is ideal for device and machine builders, as it simplifies designs and reduces material costs,” Marshall says. “We are now on our seventh-generation chip, and, in this design, we added analog technology for the first time.”

Niels Trapp, vice president of business development at Hilscher Gesselschaft für Systemautomation, says the advantage of having software and hardware from one company is that the two disciplines are closely interlinked during chip development.

“The result is a highly efficient, compact solution with reduced connection costs in a small form factor. This makes the netX 90 the ideal choice for extremely demanding applications, where, for example, network, drive and motor merge with one another in a limited space,” Trapp says.

The netMotion implementation on the netX 90 chip is designed for lower-performance motion-control applications that don’t require complicated algorithms and computing power, Trapp adds.

The system is ideal for motion-control applications in networked factory and process control systems, assembly, packaging and robotics, adds Marshall.

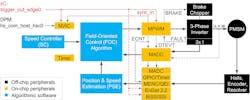

“With netMotion, developers get real-time Ethernet connectivity to networks such as EtherCAT, EtherNet/IP, Modbus and Profitnet, as well as general-purpose motor- and motion-control functionality,” Marshall says. “NetMotion acts as an interface between motion sensors and the real-time Ethernet networks. It supports deterministic, low-latency, network-synchronized control of field-oriented-control-based motor-control-system designs (Figure 3). It works with a variety of motion sensors, including Hall effect, encoder and resolver position feedback for three-phase permanent magnet synchronous motors (PMSMs) and brushless dc (BLDC) motors.

Figure 3: The built-in motion and motor control application for the netX 90 netMotion supports deterministic, low-latency, network-synchronized control of field-oriented-control-based system designs.

“Drive technology in itself encompasses a very wide range of products and applications. Basically, a distinction can be made between decentralized and centralized approaches,” Trapp says.

In a decentralized system, part of the computing intelligence of the controller for the motion and position control migrates to the drive. “This means you have to have more powerful hardware available, which takes up more space and costs,” Trapp says.

In a centralized approach, the computing power of the controller in the system or machine determines the motion and position control. “The drive-specific data are exchanged synchronously with the drives via real-time Ethernet networks with low cycle times, which enables multi-axis operation and cost-optimized solutions in a limited space on the drive side,” Trapp says. With netMotion and the help of netX 90, the control of inverters, motors and rotary equipment can be equipped with an integrated multi-protocol network interface, he says.

Also read: Linear motion control for all

“This opens up a global market and interoperability with various control manufacturers. Once a motor is network-enabled, the possibilities are almost limitless, for example, in applications such as a servo motor in servo drives, electric cylinders and servo pumps,” Trapp says.

Hilscher also offers a development kit for netMotion, including a hardware board with accessories, development environment and software examples, as well as math modules and a sample field-oriented control (FOC).

“The NXHX 90-MC board, designed for evaluation and development purposes, also serves as a reference design and shows how a generic structure of the network interface and motor driver stage is possible with the help of netX 90. The installed software thus decides which type of motor, position feedback and application profile are used, similar to the various real-time Ethernet-based communication protocols,” Trapp says.

High performance

The need for high-precision motion-control applications is being driven by the continued adoption of lasers in manufacturing for tracking accuracy and throughput, explains Patrick Wheeler of Aerotech.

“You need to manufacture these precision parts at a very high throughput without sacrificing quality,” Wheeler says. In manufacturing environments, other factors, such as electromagnetic interference (EMI) noise, can also affect productivity.

“For that reason, Aerotech’s new Automation1 motion control platform utilizes a glass-optical fiber network called HyperWire for device-to-device communication,” Wheeler says.

Figure 4: The Automation1 motion control platform and glass-optical fiber network called HyperWire is a synchronized communication network that transmits motion trajectories at up to 100 kHz.

HyperWire is noise-immune and a high-bandwidth, synchronized communication network. It transmits motion trajectories at up to 100 kHz and can handle up to 32 axes of servo motion control (Figure 4).

The product was launched in 2019. “The impetus for this technology was to deploy a flexible, reliable communication network that would enable motion trajectories with more than double the resolution,” Wheeler says.

The platform would be useful in laser-scan-head applications, Wheeler says. For ultra-high-speed laser processing of parts, laser scan heads can move a laser spot on a substrate, while concurrently commanding an industrial laser.

“Many applications require this process to take place while maintaining tracking accuracy to within a few micrometers or less. The HyperWire fiberoptic motion bus enables high-resolution trajectories, which are the control points for the laser scan head, such that the laser processing application meets the accuracy requirements,” Wheeler says.

With HyperWire’s performance, customers can use multiple single-axis drives in unique configurations, he adds. “For example, HyperWire enables Automation1 control systems to implement a decoupled gantry control scheme utilizing two single-axis drives, which implement a MIMO-based control architecture, over the HyperWire bus, without sacrificing performance,” Wheeler says.

Overall, the types of applications that would benefit most from HyperWire would be multi-axis precision motion control, including contoured motion and move-and-settle applications, says Wheeler.

“Utilizing a MIMO control architecture over HyperWire is a specific advantage because you get all of the benefits of a MIMO control architecture without any additional cabling,” Wheeler says.

HyperWire is flexible because of its ability to communicate with different types of devices without losing performance. “Many networks claim flexibility but performance suffers. This is especially true in high-end, multi-axis motion-control applications. For example, you may be able to connect several devices, but you are forced to reduce the trajectory rates over the network,” Wheeler says.

“There is a tradeoff between the bill-of-materials price to build a servo motor drive and the speed at which the logic on that device—the servo and current control loops—can be updated. For that reason, a standard servo motor drive will often close the servo loop at somewhere between 1 and 4 kHz. Automation 1’s servo motor drives close the servo control loop at 20 kHz,” Wheeler says.

The component’s reliability comes from the use of a glass optical fiber physical layer, accurate in any operating period or environment, Wheeler says. “Machine builders and end users can use the same single-axis drives for any application or machine build and therefore stock a lower amount of spare drives or get a spare more quickly, should they experience a failure,” Wheeler says. “If the machine builder or end user is considering a multi-axis drive, they should consider maintainability items, such as pluggability and swappable single-axis amplifiers. They should also make sure that buying multi-axis specialized hardware does not equal a sacrifice in performance.”

With design and configuration tools, HyperWire devices and control schemes are quickly configured, says Wheeler. “Axes on the HyperWire network, if powered on, are automatically detected in the Aerotech Automation1 Studio software’s machine setup utility,” he says. Users can set up their networks with the machine setup software wizard, with the proper electronic devices, the required HyperWire cables and a power supply for the drive electronics.

Figure 5: SureServo2 System is designed to allow users to create solutions for many types of common motion and application needs with built-in control features.

Serving control

Customers with advanced applications are expecting ease of use and easy setup from their motion-control components. “Controls engineers are busy coordinating and integrating many technologies to provide complete solutions and don’t have time for learning the intricacies of complex products. They expect products to be easy to set up, apply, maintain and troubleshoot,” says Chip McDaniel, technical marketing for AutomationDirect.

In May 2021, AutomationDirect launched the SureServo2 Servo Systems product family to provide easy-to-implement-and-maintain servo systems. The line of servo system components includes servo motors, servo drives, premade cable sets, in various lengths, flexing and non-flexing, and I/O connection accessories.

“AutomationDirect SureServo2 servo systems take advantage of powerful processors and software to deliver wizard-like functionality,” McDaniel says. “Graphical user interfaces provide simple setup and programming, while support of standard communication protocols makes it straightforward to integrate servo drives with other systems.”

Built-in control features allow users to create solutions for many types of motion and application needs, such as internal motion (Figure 5). “While an external PLC or PC can certainly send commands to a drive, for many smaller systems it is better for the servo drive to provide native capability for users to configure logic and mathematical operations,” McDaniel says. “In some cases, the drive can be an all-in-one logic and motion control solution.”

This can eliminate the requirement for an external motion controller or PLC to handle the path planning. “Even if a PLC is being used for the application, there is a clear delineation of responsibilities: the PLC is handing all the logic, and the servo system is handling motion. Maintenance and troubleshooting are easier because there is a single system,” McDaniel says.

For applications where a separate PLC or standalone motion controller is the best choice, SureServo2 can work in those applications, too, adds McDaniel.

The system can also be used in electric gearing, where many secondary axes can be commanded at speeds that are a ratio of a primary axis. “The ratios and even phase relationships can be changed instantly and on the fly, so that machine elements move at the proper relational speed without needing gearboxes,” McDaniel says.

This would be advantageous for any applications where belts and pulleys are being used to synchronize multiple axes or where the flexibility to change a gear ratio on the fly is needed.

Servos with electronic camming capability operate mechanisms over a stroke and duration profile and can reproduce these mechanical system movements. This type of setup can also be readily changed to meet the needs of machine and product changeovers.

Rotary and flying shears cut material on the fly and require precise servo operation to move the cutter to match the product material speed, McDaniel says. “The cutter head needs to rotate quickly between cuts but must slow to the speed of the web or material during the actual cut. The wizard allows you to import a table of custom positions from a spreadsheet or other source to set up epicyclic motion quickly and easily,” he adds.

“Packaging, cutting and printing machines often take advantage of registration, which is using a detector to identify where moving product is located, so a servo-driven portion of the machine can be driven exactly to where it is needed,” McDaniel says. He adds that the system is ready for most servo applications, right out of the box.

“Four automatic tuning modes will tune practically any load dynamically, even loads with a high inertia mismatch,” McDaniel says. Wizards speed the setup of advanced features, and a built-in software-based oscilloscope lets users make real-time adjustments to command signals or actual shaft position.

Users start with the online configuration tool to remove the guesswork on which products are needed, so users get what they need the first time, McDaniel says.

Hardware features include 100 W to 15 kW motors, with 230 Vac power supply; 3.1 kHz high bandwidth; brake and nonbrake motor options; higher peak torque and larger intermittent duty zone per model; high load inertia mismatch, up to 50:1 or more, depending on the application; dynamic braking for a disabled, overloaded or faulted motor; and regenerative braking to take advantage of and maximize deceleration.

Control features include position terminal mode for pulse/direction and clockwise/counter clockwise (CW/CCW) control; speed and torque control modes; position register mode, where an internal indexer uses preconfigured or dynamic registers in the drive for position targets; full closed-loop control mode with an optional external encoder; internal motion sequencing and I/O commands, up to 99 sequential unique moves without the need for a PLC; built-in electronic camming that can define numeric cam tables in the drive or import values from a spreadsheet or other external source; and a capture-and-compare function for applications requiring registration.

Four tuning modes cover all applications, McDaniel says. Up to 90% of applications are covered by one-touch auto tuning, where the drive tunes the motor without any motion; normal auto tuning, where the drive tunes the load while an external controller of the drive’s internal indexer provides point-to-point moves; and assisted tuning, which comprises three modes where the drive tunes the motor while moving and the user adjusts responsiveness while the drive is analyzing the system.

For applications not covered by those three, the fourth option, manual tuning, includes more than 20 parameters for flexible tuning.