Dave Perkon is technical editor for Control Design. He has engineered and managed automation projects for Fortune 500 companies in the medical, automotive, semiconductor, defense and solar industries.

With the three leading technologies of business and industry today—Internet of Things (IoT), the cloud and big data—the world is moving quickly into a new era: the Overwhelmed With Information Age. Too much information is a reality. Digging through this information to find a problem and then its solution can be an impossible task, and trying to master the information to make decisions is becoming more and more difficult.Put simply, the IoT provides the connection, the cloud provides online storage and convenient applications, and big data provides analysis, management and maintenance of information, which, when combined, can overwhelm the data users and decision makers. Fortunately computers and specifically machine-learning applications, although in their early stages, can help.From the industry or manufacturing side of business, machine learning can be applied to just about any control system that is smart enough to actually alter how it controls a machine in response to changing conditions, but there is much more to it than that. The three leading technologies of today are all feeding this field of artificial intelligence (AI). How will these technologies feed machine learning and allow machine design, control systems, production, maintenance and business practices to improve? It’s a work in progress, but it’s learning and can help from the ERP level and schedule board down to the machines and the plant floor processes.

Solving problems

"Machine learning will help machine builders, integrators and end users by allowing the machines to solve the problems that typically can only be done by humans and, in some cases, can’t even be done by humans," says Matt Wicks, vice president, product development, manufacturing systems for Intelligrated, a provider of automated, intelligent conveyance and robotic handling systems in Mason, Ohio.

"When discussing machine learning, the top item is the ability to process large amounts of data analytics to identify patterns and trends not readily visible using traditional statistical tools. This information can be leveraged for preventive maintenance and/or machine and system optimization improvements. When considering machine learning for robotic and computer vision tasks, such as object recognition and pose estimation and complex motion involving perception, it provides for improved robotic operation and performance (Figure 1)."

Figure 1: Machine learning can help to improve vision-guided robot applications.

Source: Intelligrated

Machine-learning techniques can be applied to the aspects of perception, allowing the equipment to respond to changing and novel scenarios, continues Wicks. "Perception is a component and, relatively speaking, low-hanging fruit for AI," he says. "Coupling vision, motion and machine learning can provide more impressive results, allowing not only the perception tasks to perform at a higher level, but allowing the perception to be combined with the machine motion, yielding performance levels that may be more optimal and capable of functioning in a much wider variety of scenarios."

While we are still a long way from leveraging machine learning to help design material-handling equipment, in the short term, it's feasible to see AI/machine learning techniques applied to optimize certain operations, explains Wicks. "Robotic technology is moving away from the traditional ‘program it and let it do the repetitive operation over and over again’ to a ‘move, see, think, act’ model," he says. "This roughly translates into machine vision, processing algorithms and physical motion. Machine learning can help individually with each of these steps, but, when taken as a whole, it can yield some very impressive results."

Not only is machine learning being developed at the machine level, interest is increasing across industry. "One thing you might want to take a look at is the Google Trends comparing the search volumes for machine learning vs. artificial intelligence vs. neural networks vs. late-comer deep learning," notes Michael Risse, vice president and CMO at Seeq. The interest in AI peaked in 2004, dropped to a low in 2008, which continued until a resurgence of interest in the past year and a half. Artificial intelligence and machine learning are leading current interest in 2016.

"There might be other terms to consider—prescriptive analytics, for example—and then there are the process-industry-specific analytics tools such as advanced process control (APC), statistical process control (SPC), multivariate analysis and even application performance management (APM),” says Risse. “It’s a long list. What is machine learning exactly? Is it one thing, or is it all of these things? And why the resurgence of interest?"

The IoT, cloud and big-data technology are likely pushing the interest in machine learning and how it will be used. "Without machine-learning techniques, the future of IoT solutions would certainly be limited," notes Nikunj Mehta, founder and CEO at Falkonry. "IoT solutions are complex in the way biological systems are complex. Systems are composed of large numbers of interacting things that each possess their own complex behaviors; structure and behavior are not fixed, but evolve over time. IoT systems are great at producing data, but, without automated learning techniques, the data volumes drown effective use. Builders and users of IoT solutions need systems that learn and that are adaptive."

What is machine learning?

How machine learning will influence and improve machines and manufacturing is a tough question, but the definition of machine learning is not science fiction, and it depends on who you ask.

To some, it is the ability to adjust and improve the machine or process. "In the context of manufacturing and automation, it is the ability of a machine to recognize advanced patterns—not just input and output states—in its process, understand what they mean to its process and allow for adjustments to the process in real time to maintain efficient operation (Figure 2)," says Dan Seger, principal application engineer at Rockwell Automation.

Figure 2: Controllers of the future will provide machine learning and process adjustments at the machine control enclosure.

Source: Intelligrated

Machine learning is any number of algorithms that use an optimization objective function to help a computer interpolate or extrapolate trends from a learning data set to apply to unknown data, explains Anthony Skjellum, PhD, professor of computer science and software engineering at Samuel Ginn College of Engineering, Auburn University in Auburn, Alabama. Skjellum’s view is more computational. Correlations can be determined. Identifying causation—that the correlations mean something— is still the human's job.

"Humans make and break models constantly," says Skjellum. "That's a key aspect of human intelligence. Machine learning tries to show correlations. Humans then abstract models, do further experiments and determine if the model is a useful abstraction. It is a closed-loop process. There can't, at present, be a purely AI data scientist."

A wider view of machine learning

Others prefer a wider software view of machine learning. "To us machine learning is the ability for software systems to use observations of the world around it," says Mike Haley, senior director, emerging products & technology at Autodesk. "The physical, virtual and textual worlds are used to understand and predict behaviors and semantics that the program was never explicitly programmed to understand. In that way, these machine learning systems are truly dynamic."

Also read: Case Study: A catalyst for smart manufacturing with Germany’s SmartFactory

Perhaps the better way to look at machine learning is to consider the computer and market angles separately. "There is a computer-science and a market answer to what machine learning is," comments Seeq’s Risse. "The computer-science answer is machine learning uses automated and iterative algorithms to learn patterns in data, so you don’t program the endpoint solution at the outset. Instead the algorithm adjusts itself—by learning from one data point to the next—to solve a particular problem as part of the process, using either a supervised, training-set or unsupervised starting point."

The market answer is that machine learning is on the cusp of joining big data and the IoT as a marketing necessity for modern software offerings, such that the technical definition or correctness of any particular solution is lost in the hype, continues Risse. "And that is just within machine-learning offerings,” he explains. “There are many other computer-aided insight tools vying for attention at the same time: deep learning, machine intelligence, artificial intelligence. The answer is getting more marketing-focused over time, given the competition within and across the ecosystem."

Machine learning is here to stay, says David White, senior research analyst at ARC Advisory Group. "Machine learning is going to be an essential technology moving forward," he predicts. "In practice, data from the Industrial Internet of Things is going to be big data for industry. We have reached the point where data visualization and the human eyeball aren’t going to be enough. We are generating a much greater volume of data at a much greater speed than ever before. This presents challenges and opportunities."

The challenge is to make sense of all the data in time to make the right management or operational decisions, explains White. "Machine learning can help here," he says. "For example, machine learning algorithms executing close to assets and processes—at the edge—will be able to work with this complex data and make intelligent decisions in real time. The opportunities then are to improve productivity by reducing scrap or cut maintenance costs by moving to predictive maintenance, rather than preventive maintenance. This is a clear benefit to end users. However, machine builders can also take advantage of machine-learning technologies to gain competitive advantage."

Adoption of machine learning

Got data? "The key thing about machine learning is that the performance of the algorithms improves over time," says ARC’s White. "There is a long-standing rule of thumb among machine-learning experts that a weaker algorithm with more data will ultimately outperform a stronger algorithm with less data. In this way, I think machine learning can help to make control systems much more agile and responsive in meeting changing needs."

Adoption of machine learning in heavy industrial settings is still very limited, largely due to its only recent emergence as a viable control method. "You’re seeing it begin to appear in some robotic systems—mainly related to computer vision and path planning—and object-avoidance drone technology, but it’s only just beginning," says Autodesk’s Haley. "Perhaps the biggest uptake in machine learning is in the IoT sector, where learning predictors of failure modes in devices is of significant value. In all of these cases, the inherent ability of new machine-learning systems to find and predict patterns in many often-messy data signals is driving the state of the art."

Different industry segments are at different points on the adoption curve, but generally it's still very early in adoption process. "To really implement machine learning at the most advanced level is a very expensive proposition at this time, so the need has to be very critical, as well, says Rockwell’s Seger. "However, the technologies and user knowledge in this area are advancing, which will lead to lower costs to implement. This further accelerates the adoption process."

Also, users are realizing they don't have to make huge jumps in technology to see value, notes Seger. "Small steps along the path can pay valuable dividends as the technology and knowledge base grow," he says. "This is a result of IoT. Manufacturers need the data to help to identify meaningful patterns in the process. Much can be done with simply identifying key patterns in the process and knowing what they mean."

Real, machine-learned benefits

Human intuition is limited; machine learning can point out correlations that are subtle and that humans can't see; it makes people smarter when used wisely, explains Auburn’s Skjellum.

Machine learning actually helps to achieve a goal of purer, less biased investigation when used properly. "If you start with a big bunch of data, and machine learning gives you a correlation, the scientist or engineer hypothesizes a causation, does experiments, maybe more machine learning, and concludes whether the hypothesis, concept and relationships are real or coincidental," says Skjellum.

Benefits include more efficiency in the form of reducing downtime and a growing capability to predict failures and avoid unplanned downtime events, says Rockwell’s Seger. "A second benefit is identifying operation speeds that are more cost-effective than simply running at maximum speed," he says. A third is discovering which system designs are less vulnerable to breakdowns or other efficiency losses.

Autodesk’s Haley sees benefits mainly by accelerating the design and development process through learning from everything that has already been done. "In this way designers and engineers can rely on a smart system to guide them through a design, making sure they are incorporating the best approaches, avoiding duplication and tracking most closely to the desired solution," he says. "One simple example here is the amount of duplication of designs or components that can occur over many years in a large firm. This can be almost entirely eliminated through machine learning and real-time guidance provided to a designer."

As the entire lifecycle of products becomes better instrumented, machine learning offers more opportunities. "Well-understood patterns discerned via machine learning from product-usage data can point to design and operational improvements," says Falkonry’s Mehta. "Likewise, machine learning can use data collected from production processes to identify conditions and guide process improvements."

Most manufacturers struggle with creating and maintaining accurate process data, such as production time standards, yields, run times and setup times, says Jim Cerra, cofounder and CEO of PlanetTogether. "This data is instrumental in creating optimized production plans and schedules and driving higher productivity and on-time delivery," he says. "Predicting machine downtime, absenteeism and other probabilistic data is even more difficult, but it would be helpful in assessing the risk of customer-service issues due to delayed delivery and revenue-attainment shortfalls for the company."

If the computer can learn from watching these manual changes, systems can then begin to suggest or even automate the work, freeing more of the planner’s time to make the tough decisions that only a human can make, says Cerra.

Machine-learned advances and improvements

The biggest advancements related to machine learning will be centered on data collection. "Right now, it's a brute-force approach where lots of disparate data is collected and mined for patterns that have actionable meaning," says Rockwell’s Seger. "In the future, as users identify which data points have the most value, data collection will focus on those specific data sets, and the collection process will become more streamlined."

The biggest gains will come when streamlined data collection and condition monitoring are combined to create ideal operating profiles for processes, explains Seger. This is when real-time control will have a significant impact.

"As computers get faster and algorithms continue to be refined for machine learning, greater inferences become possible in near real time or real time," says Auburn’s Skjellum. "Combining machine learning with predictive simulation and feedforward and feedback control can help to address complex control-system objectives, while also enhancing the potential for detecting cyber threats or other kinds of disturbances."

Lots of system designs done with machine learning produce results that are not intuitive to the best human designers, says Skjellum. "There are many process variables and figuring out the most important ones—a kind of identification problem—is not new; it is an important part of systems and control," he says. However, looking at the vastness of historical data or the vast number of sensors in a plant for correlations and failure prediction is a new and emerging machine learning example.

Improved robots, machines and processes

"Autodesk is experimenting with robotic systems that watch and learn from skilled craftspeople, and then work alongside these people to add precision, repeatability and/or safety to their work," says David Thomasson, principal research engineer at Autodesk. "As the new breed of collaborative industrial robot arms, such as the Universal Robots models designed to work in close proximity to people, become more common, there is a need for more intuitive interaction with these machines (Figure 3). This is being enabled by machine-learning systems that automatically determine the best course of action based on their understanding of human preferences and abilities, along with a more complete awareness of the design and the situation in which it is to be realized."

Figure 3: An engineer works with a robot to develop a collaborative robot that adjusts its operation based on the capabilities of the human it is working with.

Source: Autodesk and Universal Robots

The most prevalent current solutions allow for identifying trends in the process that have had a large, negative impact on efficiency, says Seger at Rockwell Automation. "Once identified, those issues can be more quickly resolved,” he says. "However, these systems are not yet able to predict future issues. Predictive systems are still quite expensive to implement, so they're not used en masse."

As the use of predictive systems grows, the initial goal will be identifying impending issues, so they can be resolved in a scheduled and controlled manner, continues Seger. "Beyond that, predictive systems in the future will not only identify impending issues, but also modify how the process is operating, so as to avoid the issue for as long as possible," he says.

A quick look at the tools

"As IoT, IIoT, and Industry 4.0 concepts rapidly gain ground in manufacturing applications, machine builders and manufacturers are investing in tools and devices that connect machines to the enterprise network with the ultimate goal of harnessing big data produced at the controller and field-device level," says Daymon Thompson, automation specialist at Beckhoff Automation. "Machine learning will become more commonly deployed by manufacturers, bringing benefits such as data anomaly detection; failure prediction and prevention; or insight on how to optimize processes."

With machine learning, as already proven out by major IT companies, advanced data modeling and analysis can be accomplished without the end user having to know exactly which process values are within acceptable ranges or how long data can stay over a given threshold before intervention by plant personnel becomes necessary, continues Thompson.

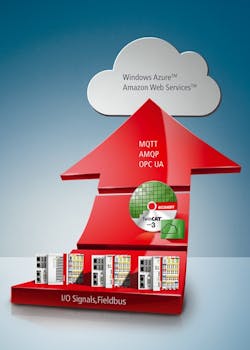

Another force driving the evolution of machine learning in manufacturing is the availability of easily accessible, affordable, cloud-based machine learning services such as Microsoft Azure and Amazon Web Services (Figure 4). These services greatly reduce the barrier to entry for industrial manufacturers who are interested in exploring machine learning, says Thompson.

Seeq, for example, provides an application dedicated to time-series data investigation. It allows Google-like searches, collaboration in real time and interaction with analog data series like never before. Seeq is intuitive; it’s visual; and it connects to just about any process historian to find answers in the data.

Figure 4: Another force driving the evolution of machine learning in manufacturing is the availability of easily accessible, affordable, cloud-based machine learning services.

Source: Beckhoff

"A CoPilot software feature uses available server computational capacity during idle times to find a better schedule for companies automatically," notes Cerra at PlanetTogether. If plans are found that result in higher KPIs, such as better on-time delivery, increased cash flow or reduced costs, then the new scenarios are automatically presented to the planners who can compare the scenario to the current plan and choose the best option. This requires massive amounts of computer computations, especially in complex factories with tens of thousands of orders in the schedule and quadrillions of possible solutions to choose from.

Engineering use

“There is a wealth of information available on the techniques associated with machine learning," states Intelligrated’s Wicks. "Google has recently open-sourced its machine-learning software called TensorFlow. Google believes machine learning is a key ingredient to the innovative products and technologies of the future. The research in this area is growing fast but lacks standard tools. By sharing, Google believes it can create an open standard for exchanging research ideas and putting machine learning in products."

Machine learning can certainly accelerate the design process all the way through to physically realizing a product, says Haley at Autodesk. "It will mean less time designers or engineers spend on tasks not directly related to the creative aspects of their jobs," he says. "One of the most important aspects of machine learning is to have a sufficient quantity of data for it to learn from. Making sure the data in your company is gathered somewhere, reachable and understandable will go a long way to successful adoption of future machine-learning technology. Most of the human-computer interaction models that relate to machine learning strive to avoid any particular understanding or skills on the part of the user."

The functionality surfaces as suggestions, recommendations, alerts or even something completely transparent to the user, says Haley. "The design and engineering software world is still working on this, so just keeping up to date on the latest software available would be a good start," he says.

Engineers and users should learn how to use databases and the accompanying analytics, as well as condition-monitoring technologies and how they fit in with their processes, suggests Seger at Rockwell Automation. "Machine learning at its core is based on these two technologies, so they need to be well-understood," he says.

Learning machine learning

"Machine learning is widely used in e-commerce, with Web search engines ranking pages based on what individual users previously viewed or searched, in finance for fraud detection and with autonomous robots that decipher new situations not explicitly programmed by the designer," explains Beckhoff’s Thompson.

There are a lot of packages that will help, and the fundamental algorithms are well documented, says Aubutn’s Skjellum. However, it is as important or more important for engineers to understand the limitations of machine learning and how to interpret results, compared to learning to use canned packages.

"Fortunately, this has never been easier to get educated on machine learning," says David White at ARC Advisory Group. "First, there are some great courses available online, offered by organizations like Coursera and edX, which are mostly free. Second, open-source software and the cloud make it much easier to experiment with machine learning at little or no cost. There are number of cloud-based platform-as-a-service (PaaS) solutions where you can just sign up and get started with machine learning for free. Most of the solutions have tutorials, and they are quite modern and visual, as well. If you're cloud-phobic, as an alternative, there are open-source solutions you can also download and play with for free."

Machine mentoring

Several of your work colleagues may be computers in the future and will possibly be great mentors. "I think that cognitive AI can certainly be a source of mentoring, and IBM Watson could certainly be giving advice sooner than later in specific niches, says Skjellum from Auburn University. "Also, machine learning that helps you to discover patterns that are constructive and destructive to personal and professional success, such as procrastination and eating poorly, are on the near horizon. This is not a long-term thing; it is coming shortly—months not years."

These same things can apply in industry, continues Skjellum. "Mining the behavior of a company over time to show success and failure patterns in hiring, promotion and business processes seems likely," he says. "Now, to mentoring, that is simply a decision support approach based on what works versus what fails. That can be not only for a given company but also learned over comparable industries and cross-correlated with successful firms in adjacent spaces."

So mentoring of sorts from machines is a logical thing, says Skjellum. "In control systems, which depend heavily on math modeling and understanding nonlinearities of systems and also the complexity of human interactions, there is clearly room for operators to be mentored by computers in complex decision making scenarios," he says. "Collision avoidance systems for aircraft, and coming now for cars, are a kind of decision support. Humans deal only with a few variables at a time; while control operators gain intuition over time, they don't necessarily make the right choices under stress, or even the right choices when confronting situations that are uncommon. Think Chernobyl."

Future evolution

As more and more computing power emerges and computational elements are also optimized for the machine learning algorithms—such as special-precision massively parallel general-purpose graphical processing units are doing nowadays—faster and faster machine learning will become a reality, says Auburn’s Skjellum. "Distributed learning on handheld devices will complement that for quick and dirty decision making under uncertainty, right at the user's fingertips," he says. "Technologies such as Siri and Cortana will become digital assistants that help more and more, while engineers will build the machine learning directly into the online processes of industrial systems as integral, rather than off-line or near-line."

Machine learning will gradually become more competent at sensing—taking lots of signals, including video and sensor data and understanding patterns in them—to the point that they’re far better at it than humans could ever be, predicts Autodesk's Haley. This will allow software systems to more seamlessly understand and interact with the world around them. That said, this is only a tiny step toward realizing a machine-learning future where the systems themselves can perform truly intelligent reasoning. That’s still a long way off, but, along the way, there will be a lot of interesting and useful solutions such as generative design systems, adaptive industrial systems and cognitive computing.