AI for machine builders—can it live up to the hype?

Machine builders are facing an array of complex challenges. From supply-chain disruptions to seismic shifts in product designs and demands, machine builders must navigate all these issues while balancing cost and quality. Making matters worse is that all these goals must be achieved while managing ongoing talent shortages.

While it can’t fix every problem in machine building, artificial intelligence (AI) offers transformative benefits. Forward-thinking machine builders are now leveraging this new technology to enhance automation and improve quality for a staggering advantage in the manufacturing marketplace.

What machine builders need to know about AI

Although manufacturers are more familiar with AI than ever before, there are still a lot of misconceptions about the technology. In particular, there’s some confusion around what AI is and isn’t capable of, as well as how it integrates with existing manufacturing technology.

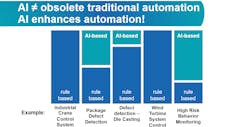

One of the biggest misconceptions is that AI is like a magic wand that can fix any challenge you may be facing. While AI is incredibly valuable for a broad range of applications, the reality is that, like any tool, there are situations where it’s simply not applicable (Figure 1).

Another common misconception is that AI will replace programmable logic controllers (PLCs). This simply isn’t true. Instead, AI complements PLCs to enhance their capabilities and control of equipment (Figure 2).

How AI can transform machine building

Now that we’ve addressed a couple of common myths, let’s take a look at some of the ways AI can transform machine building.

In brief, AI can dramatically enhance automation, assist with predictive maintenance and generally enable greater agility in machine building.

Consider predictive maintenance. One of the most impressive capabilities of AI is its ability to analyze large datasets and identify patterns that would be either invisible to the human eye or prohibitively time-consuming and expensive to identify manually. With a collection of data on different machines’ temperatures, behavior and even environmental conditions, AI can predict with a stunning degree of accuracy when specific machines will require specific maintenance. This can significantly reduce unplanned downtime while maximizing the life of the machines and reducing maintenance expenses.

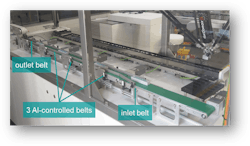

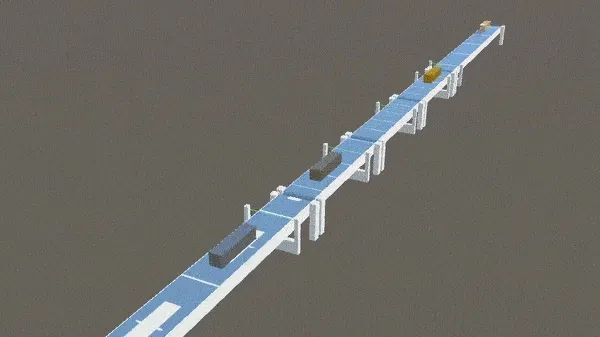

Likewise, machine builders can use AI to reduce the need to spend valuable resources on hardcoding solutions for complex programming challenges. Consider a machine builder who is building machines for a bottling line for a client in the beverage industry. A common problem on these lines is spacing inconsistencies between bottles. In order to ensure the bottles are properly labeled, filled and packaged, they must be spaced evenly. To manually program automation that can accurately detect and correct spacing inconsistencies is immensely resource-intensive (Figure 3).

The engineering team must account for a plethora of variations in sensors, conveyor belts and so forth on each line (Figure 4). Instead, machine builders can train an AI model in the virtual world to address the same challenge in a fraction of the time.

Another impressive benefit of AI is its ability to predict product quality by evaluating certain parameters regarding production. Artificial intelligence can be trained to do so by analyzing a data set with large numbers of products that both meet and fall short of quality standards, as well as certain parameters of their production. These parameters may include the temperature of the machine, automated optical inspections, machine vibrations and even conditions like the humidity of the facility.

The AI could then identify which parameters are most likely to cause defects, allowing manufacturers to predict which components may require further quality-control inspection and which can pass to the next step in production.

The opportunities and challenges of implementing AI

While AI offers machine builders enormous opportunities, its implementation also presents several challenges.

Establishing proof of concept is easy, but successfully running AI productively at scale poses more difficulties. In fact, only 54% of projects make it from prototypes to production, according to a survey from Gartner released in 2022.

There are a variety of reasons why this occurs. One of the most common hurdles is data—either a company hasn’t collected enough of the relevant data or the data is of poor quality. Other companies struggle to gather actionable insights in a timely fashion, while others run into challenges when the AI needs to be retrained.

So, how can we overcome these challenges? In short, machine builders looking to successfully implement AI need the right infrastructure, the right software and the right partners.

The infrastructure typically includes edge devices to collect data, such as high-definition cameras or sensors. These devices will also need a reliable, seamless cloud to connect to and compile the data cohesively in a single location. With the right software, companies can easily access this data, analyze it with AI and create practical insights that drive real value.

To address these challenges, machine builders must work with an experienced partner that knows how to apply these tools for the maximum return on investment. The right partner can even help to address limitations with limited or poor data by training AI with synthetic data. Training AI with a virtual replication of your unique machine building environment, you can achieve considerable cost and time savings.

Revolutionizing machine building with AI in the right hands

At the end of the day, AI truly is a revolutionary new technology for machine builders, but it’s only as effective as the team implementing it. While it’s amazing to see the enthusiasm and excitement around AI, machine builders have to make sure they’re implementing this tool in a way that truly suits their unique goals and situation.

The sky's the limit. How will your team raise the bar with AI?

Steffen Klawitter, digital enterprise lead architect at Siemens Digital Industries, will present "How Can Artificial Intelligence Create Manufacturing Agility?" at 11 am on May 22 during A3's Automate 2023 in Detroit. Contact him at [email protected].

Register for the conference at Automate Registration.

About the Author

Steffen Klawitter

Siemens

Steffen Klawitter is head of digital services and chief architect at Siemens Digital Industries. Contact him at [email protected].

Leaders relevant to this article: