Hybrid technology combines active and passive cooling in cabinets

Michael Milam is vice president, industrial automation, at Rittal.

What have been the biggest improvements in enclosures over the past five years?

Sustainability is becoming an increasingly important factor in customer purchasing decisions, and they seek companies that follow sustainable practices focused on reducing their carbon footprint.

Innovative climate control that uses active and passive cooling technology helps to achieve an average of 75% energy savings compared with conventional cooling units, which translates into a significantly reduced carbon footprint. This hybrid technology features two parallel cooling circuits that can operate independently or in tandem with each other depending on the temperature fluctuation. These two passive and active cooling circuits continuously adapt perfectly to the ambient conditions and with maximum efficiency. The result is a long service life for the installed components thanks to reduced temperature fluctuations (Figure 1).

What’s the most innovative or efficient enclosure application you’ve ever seen or been involved with?

Michael Milam, vice president, industrial automation, Rittal: When it comes to innovative enclosure applications, electric-vehicle (EV) charging stations are a hot topic. The transition to electric vehicles, on the global stage but especially in the United States, has gained significant momentum during the past five years. And while electric-vehicle manufacturers like Tesla have grown beyond niche status, the big three automotive manufacturers in the United States (General Motors, Stellantis and Ford Motor) have not only gotten onboard with EVs, but some of them are actually leading a more mainstream charge toward the adoption of EVs on a mass scale.

With the influx of EVs on America’s roadways, the automotive industry must also address the infrastructure required to power these vehicles. While the demand for EV charging stations, both current and future, is driven by consumer demand for increased EV production, it’s also being advanced by federal initiatives and programs designed to curb the use of fossil fuels and reduce the nation’s carbon footprint.

The Biden Administration’s American Jobs Plan set the goal of building a robust national network of more than 500,000 EV charging stations to make powering electric vehicles simple, convenient and efficient. In addition, the plan aims to make America the standard bearer for electric powered vehicles by allocating $7.5 billion for EV charging infrastructure and more than $7 billion for the critical materials necessary for batteries, components and recycling; triggering investment commitments of more than $100 billion from private companies to make more EVs and component parts in America, create jobs for our autoworkers and strengthen our domestic supply chains; and providing a host of financial incentives for automakers to ensure that more than 50% of their sales are electric vehicles by 2030.

With these factors in play, EV-charging-station producers are now off to the races to design and engineer EV charging stations in the most efficient way possible. But global factors like supply chain disruption, scarcity of component parts and rising shipping costs have become important challenges for designers and engineers to overcome when specifying the products for station buildouts.

One solution to these challenges is partnering with an enclosure solution provider before you design your charging station, and a second solution is sourcing standardized enclosures and accessories that provide superior flexibility and capacity for customization. Both of these strategies help reduce costs, decrease lead time and streamline the entire EV charging station design and engineering process (Figure 2).

It starts with having the vision for end-to-end transparency and visibility into every step of the design and engineering process to optimize their automation and control manufacturing. With the power of Industry 4.0 and IIoT becoming more realized, original equipment manufacturers (OEMs) are moving to a complete digitalized production model that unifies everything from part procurement to product delivery.

Using powerful digital software programs and computer-aided-engineering (CAE) services for machine, plant and control-cabinet engineering, manufacturers and their partners are paving a simpler path in production and cutting the complexity. Panel builders and machine builders have streamlined workflows for installing controls components, electrical wiring and panel assembly, and system integrators can then reduce downtime and leverage greater degrees of customization.

The synchronization of each individual action along with detailed reporting, real-time updates and data/schematic storage and sharing help manufacturers overcome some of the more common stumbling blocks, such as increasing pricing pressures to be able to provide the right product at the right time within the right budget, especially as competition breeds a race to the bottom line; skilled labor shortages that can result in increases in scrapped materials and revisions/alterations; delivery pressures due to the rapidly changing and real-time demands that manufacturers must respond to; onboarding new employees, which is easier with data-driven, front-end engineering, taking the guesswork out of panel wiring and assembly; and inefficient workflows via antiquated data capture, storage and communication systems.

CAE software gives panel builders, machine builders and system integrators a powerful tool to not only address these challenges but avoid them altogether. In addition, manufacturers and their partners eliminate a host of manual tasks and processes to enhance product quality and precision while also reducing production costs.

With this solution, manufacturers and their partners can wave goodbye to working reactively in variant-rich environments; instead, they’re able to work proactively to be more agile and nimble as new markets emerge, as existing markets diversify and change and as demands shift.

The bottom line: cutting-edge innovation is a completely digitalized design environment that can simplify and streamline the automation and control manufacturing for any manufacturer and its partners (Figure 3).

When it comes to energy-efficient enclosure applications, here are two examples that we’ve seen where plants were able to reduce energy consumption and save cost by having a climate-control analysis of their plants.

In a Wisconsin food-and-beverage plant, the climate-control units were experiencing a 50% or more reduction in useful life. We provided a schedule for repairs and replacements, and it resulted in lowering the energy costs year-over-year, zero air-conditioning (AC) failures for one year, and decreased total costs and downtime.

In a Midwest automotive plant, we provided a plan to scale model types from 21 down to nine types across 160 units. This provided the potential to lower maintenance costs, repairs and inventory on hand; it gave them insight into opportunities to reduce up to 80% of annual AC unit energy consumption from more than 1 million kWh; and it resulted in energy cost savings of more than $500,000 in a 10-year period (Figure 4).

Can you explain how software development has changed enclosure design and production?

Michael Milam, vice president, industrial automation, Rittal: Software has evolved into a computer-aided-engineering platform comprised of high-performance solutions where all applications access the same functions and basic data, significantly improving the quality of projects. Eliminating the need for manual data comparisons also makes processes faster, placing the focus back on essential engineering tasks. This enables enclosure assembly to be quicker, easier and reproducible, and it increases accuracy. It is possible to link all enclosure assembly steps to create a highly efficient and digitally seamless automated process.

Panel-building and control-manufacturing cycles are now incredibly tight. Tight timelines and cost efficiency are the new norm, with increasingly complex systems having to be produced in ever shorter timeframes and at lower costs.

The quality of products and services used to be the key success factor, but having the most efficient process is now just as important as a high-quality product in gaining a vital edge over the competition. Control manufacturers that focus on the entire value chain—from planning and designing a product through to the placing of orders, production, delivery and service operations—will increase their throughput, boost their efficiency and achieve crucial competitive advantages. Combining CAE solutions and automation expertise optimizes and industrializes your panel-building and control-manufacturing processes.

Business success that is future-proofed will only be sustainable if it goes hand-in-hand with the complete digital integration of products, processes and the data they generate (Figure 5).

How do enclosures figure into any digital-twin platform being used by manufacturers?

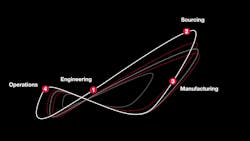

Michael Milam, vice president, industrial automation, Rittal: Digitalization, standardization and automation are key success factors to be competitive in manufacturing. They also help prevent errors, boost productivity and save both time and money. The digital twin is at the heart of this workflow and is created during the engineering process to link all downstream process steps—from sourcing and manufacturing through to operations. It is an important basis for production and also for the subsequent maintenance and repair of finished products, ensuring consistent data retention throughout the entire lifecycle of an enclosure.

The digital twin is the basis for enhanced efficiency in the engineering process to plan and design the enclosure, creating the digital twin of the real-life product in the form of a consistent data model. Planning is based on high-quality 3D data that maps the enclosure and its accessories and is complemented by project-specific component and wiring information.

Data from the digital twin is also accessed during commercial processes of the sourcing phase and can be connected to the enterprise-resource-planning (ERP) system. Generated at a single central point, it is then used on a decentralized basis and can also be added to and edited. This makes media discontinuity a thing of the past. If data needs to be modified, this is done just once for the whole system, and the entire process adapts accordingly.

The data from the digital twin enables a great many processes to be automated during the manufacturing phase, too, including panel machining, cable fabrication and the cutting of cable ducts or support rails. This is made possible by using manufacturer-neutral standards for data and data communication, which improves interoperability between the various systems.

Finally, in the operations phase many data enclosures and components such as climate-control units are now equipped with sensors that generate a continuous flow of data. This data is used to offer service and energy-management activities as required during ongoing operation, which improves the availability and efficiency of machinery and equipment (Figure 6).What future innovations will impact enclosures in discrete-manufacturing operations?

Michael Milam, vice president, industrial automation, Rittal: Future innovations that will impact enclosures in discrete-manufacturing operations include the need to be more energy-efficient, climate-friendly and sustainable.

The harsh elements of outdoor applications create the need for corrosion protection coatings for the improvement of outdoor enclosures. Applications that use harsh chemicals for washdown need hygienic-design solutions for pushbuttons and hygienic-design freestanding enclosures in larger sizes. In industrial applications, processing power needs to be put at the edge—as close to where data is generated and used—to create reduced latency, more analytics and insights, open bandwidth, less storage costs and full support of real-time, data-heavy applications, such as the Internet of Things (IoT), fast network technologies, artificial intelligence and robotics.

Being able to digitally track all machine and plant documentation with a digital-circuit diagram that is always up-to-date and available from any device, anytime and anywhere accelerates processes along the entire value chain, saving time and money.

Keeping cabinets properly cool or warm is important. Can you explain the basics of thermal management within enclosures: why is it important, what causes temperature changes, and how is thermal management affected by extreme environments?

Michael Milam, vice president, industrial automation, Rittal: Heat is the enemy of extending the life of your electronics. Heat attacks your equipment from all sides: on the outside with extreme variations in ambient temperatures and inside with high thermal loads caused by the high density of components within the enclosure. The challenge is to manage temperatures consistently on both ends of the thermal spectrum in any environment. Industrial climate solutions lengthen the life of your components, optimize performance and reduce equipment failure. Time is money, and uptime ensures your operations are profitable.

The trend toward high equipment density in enclosures challenges the heat-removal process. Components, even those rated for high heat use, degrade when the heat load rises. Not only do enclosure temperatures rise from the waste heat generated inside, but also from external environmental factors.

Deployment of mission-critical enclosures into harsh environments increases the level of heat risk to the components inside. Your thermal control system must manage the impact of any factor that inhibits air flow and increases temperature.

Enclosures and thermal-management products tend to have a difficult time surviving in harsh, corrosive environments. Which enclosure components are most susceptible to failure, and what can be done to address this, as well as lifetime performance?

Michael Milam, vice president, industrial automation, Rittal: Generated heat within an enclosure must be removed efficiently, or heat damage will occur. Controlling units and microprocessors age quickly under heat pressure. If left unchecked, small nuisance malfunctions may be the first sign of overheating and lead to a sudden catastrophic failure that can cost thousands in downtime costs and derail your project timeline.

Interior heat consequences include de-rated power performance; trip faults and fluctuations in circuits; mean time between failure (MTBF) decrease; component set point drift; intermittent or catastrophic system failure; voided component warranty; factory downtime; lost revenue; delayed shipments; customer dissatisfaction; and component replacement costs.

External heat factors include ambient temperature range and humidity; factory-equipment heat emissions, level of dust or dirt; exposure to direct or indirect solar radiation; exposure to rain, snow or wind; presence of corrosive or abrasive chemicals and oils; environment requiring high-pressure wash down; and amount of natural ventilation.

Internal heat sources include power supplies; controllers, drives and servos; processors and server racks; ac drives/inverters; microprocessor control gear; variable-frequency-drive (VFD) controllers; soft starters; transformers; programmable-logic-controller (PLC) systems; communication products; human-machine-interface (HMI) systems; and battery back-up systems.

Did you know that you can double the life of your electronics with every 18 °F/10 °C drop in temperature?

Advanced climate-control technology is your defense. A methodical approach ensures the internal temperature is stable and heat-related incidents or costly shutdowns are avoided. Look for high-efficiency climate-control units with an innovative thermal-management system that offers passive and active cooling technology as it can help you save up to 75% on energy costs. This innovative hybrid solution combines a compressor cooling unit with a heat pipe for passive cooling. The compressor only cuts in when passive cooling is no longer sufficient. The patented heat pipe dissipates heat from the enclosure as soon as the ambient temperature drops below the set point. In this way, high heat loads may be dissipated at lower ambient temperatures.

Tell us about your company’s state-of-the-art enclosure offering.

Michael Milam, vice president, industrial automation, Rittal: Manufacturers have challenges with multiple production sites, speed to market, safety regulations, supply chain logistics, energy costs, data management and physical security.

Modular design, forward-thinking engineering and seamless integration make it easier for manufacturers to unify each step of the industrial-automation process, from planning to production.

The integrated planning, production, modification and deployment of critical plant infrastructure such as enclosures, climate control and IT racks create the need for a more visible production cycle to identify redundancies, streamline workflows and reduce energy consumption and production costs.

In a partnership that reimagines the industrial automation process from engineering to deployment and all points in between, Rittal and Eplan bring together a modular engineering philosophy, precise and automated Rittal Automation Systems machines, and powerful, database-driven electrical engineering to provide maximum efficiency and visibility to the panel and control-manufacturing production process.

Through one integrated value chain of engineering, sourcing, manufacturing and operations, we provide an end-to-end streamlined solution that helps to reduce costs, shorten processing times and increase productivity. It starts with Eplan providing a single source for electrical engineering and then sourcing the ideal Rittal enclosures and accessories for your application. Next is manufacturing. There is a seamless export from Eplan to feed the automated modification of enclosures and mounting panels to Rittal Automation Systems machines for machining, assembly, wire processing and wiring. Automating the engineering, sourcing and manufacturing processes reduces manual interventions and the chance for errors, as well as increasing productivity. And finally operations allow data access from one single source, as well as providing service and maintenance of enclosures. Rittal’s industrial enclosure, climate control and IT infrastructure solutions are designed and engineered to meet the toughest industrial challenges. Industry 4.0 and IoT integrations make Rittal’s products the smartest, most efficient choice for deployment across industries.

Variant-rich automotive production lines require adaptability. Rittal’s TS 8 modular enclosure design, flexibility with cooling unit mounting and innovative IT cabinets provide the customization necessary to facilitate standardized, efficient production sequences across multiple plants or sites. Our Blue e+ climate control offers reduced energy costs, as well as smart manufacturing and monitoring capabilities.

Rittal’s hygienic-design enclosures and climate-control solutions are engineered specifically for use in the food-and-beverage industry and are designed to stand up to aggressive sanitation protocols to help ensure production equipment is clean at the microbiological level.

In a highly automated retail-and-logistics industry with a wealth of environmental and installation variables, Rittal’s enclosures, climate control, IT infrastructure and industrial-automation solutions are engineered to protect the sensitive hardware necessary to facilitate speed, efficiency and transparency.

For the oil-and-gas industry, not only do Rittal enclosures stand up against the harshest environmental conditions, but our state-of-the-art infrastructure and digitalization solutions pay dividends throughout the supply chain upstream, midstream and downstream—from extraction and transportation all the way through to processing.

Colocation providers face high demands on several fronts: adaptable racks, reliable power supplies, climate control, network connections and monitoring. They rely on Rittal’s IT solutions to maximize availability and help ensure optimum security levels while maintaining flexibility and meeting all relevant global standards.

With Rittal modification centers and warehouses in Sparks, Nevada, Houston and Urbana, Ohio, operators from coast to coast have access to Rittal Automation Systems Perforex machines that perform precise and cost-effective cuts, holes, drilling and other panel modifications, as well as our large distribution network for quick delivery, regardless of your location.

Behind our state-of-the-art U.S. manufacturing facilities is a global company with offices in more than 70 countries and production capabilities on four continents, giving Rittal’s U.S. customers a true advantage over the competition and a reliable partner that can meet their needs whenever and wherever their business might take them (Figure 8).About the Author

Mike Bacidore

Editor in Chief

Mike Bacidore is chief editor of Control Design and has been an integral part of the Endeavor Business Media editorial team since 2007. Previously, he was editorial director at Hughes Communications and a portfolio manager of the human resources and labor law areas at Wolters Kluwer. Bacidore holds a BA from the University of Illinois and an MBA from Lake Forest Graduate School of Management. He is an award-winning columnist, earning multiple regional and national awards from the American Society of Business Publication Editors. He may be reached at [email protected]

Leaders relevant to this article: