A manager recently said all his people used ladder logic and didn’t know object-oriented programming (OOP). He went on to explain that the company wants to be able to reuse code.

In essence, even ladder programmers are using OOP because they are utilizing premade functions that are in the default libraries and putting that in their ladders. For example, timers are premade functions already in many libraries, and those are used throughout ladder logic.

Get your subscription to Control Design’s daily newsletter.

OOP is simply software that is divided into objects. An object can be thought of as a block, a unit or a cannister—the list goes on. But most describe this piece of software as an object so that, when you have a discussion, others may follow.

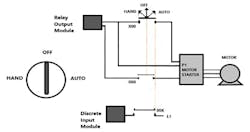

Within that object, the descriptions, associated data, procedures, interfaces or methods are included and combined to make an element. An element is typically a function. For instance, a motor starter is something that can be found in almost any system. To create an object that is repeatable in a PLC program, or library, the first step is to understand what is being interfaced with physically. Then describe the inputs and outputs in software, determine data types and then create the functionality in the function block that is wanted to be repeatable. Physically, a motor starter is described electrically as shown in Figure 1.

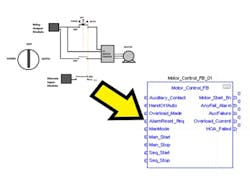

Taking the physical functionality and describing it in code may equate to the function block shown in Figure 2.

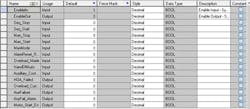

The data table is in Figure 3.

Now, the structure is set up to allow the object to be reused. Some ladder logic in the function block could look like Figure 4.

The function block code could also be written in structured text (Figure 5). Both blocks would act the same way.

Once the block is made, then it is usable for being called in a routine. The example in Figure 6 shows the function being called twice. The code is not made around it because the idea is just to show the objects usability. The code in the block is also incomplete for this example because alarming and auxiliary contact were not dealt with. The idea is to inspire the visualization of object-oriented code and how it can be reused.

About the Author

Tobey Strauch

Arconic Davenport

Tobey Strauch is currently managing brownfield installations for controls upgrades at Arconic Davenport. She has previously worked as principal controls engineer and before getting her bachelor’s in electrical engineering, was a telecommunications network technician. She has 20 plus years in automation and controls. She has commissioned systems, programmed PLCs and robots, and SCADAs, as well as managed maintenance crews. She has a broad mix of mechatronics with process control. She enjoys solving problems with Matlab and Simscape. Contact her at [email protected].

Leaders relevant to this article: