A Control Design reader writes: I've seen basic standard stacklight colors on machines for years, but now it seems there are a variety of other colors for various conditions. Are there any downsides to adding colors or flashing patterns? Do they confuse operators? And what about "smart" stacklights with advanced communication technology? Is it overkill, or are we missing an opportunity by not including them on our machines?

Get your subscription to Control Design’s daily newsletter.

Answers

Beware of color-blind ambition

Using too many colors on stacklights for machines can lead to significant issues, particularly in environments where quick and accurate interpretation of signals is critical. One of the primary concerns is the potential confusion caused by an excessive variety of colors. When operators are presented with a wide range of colors, it becomes challenging to quickly distinguish between different states or alerts. This can slow down response times or even lead to incorrect actions, which can have serious safety implications.

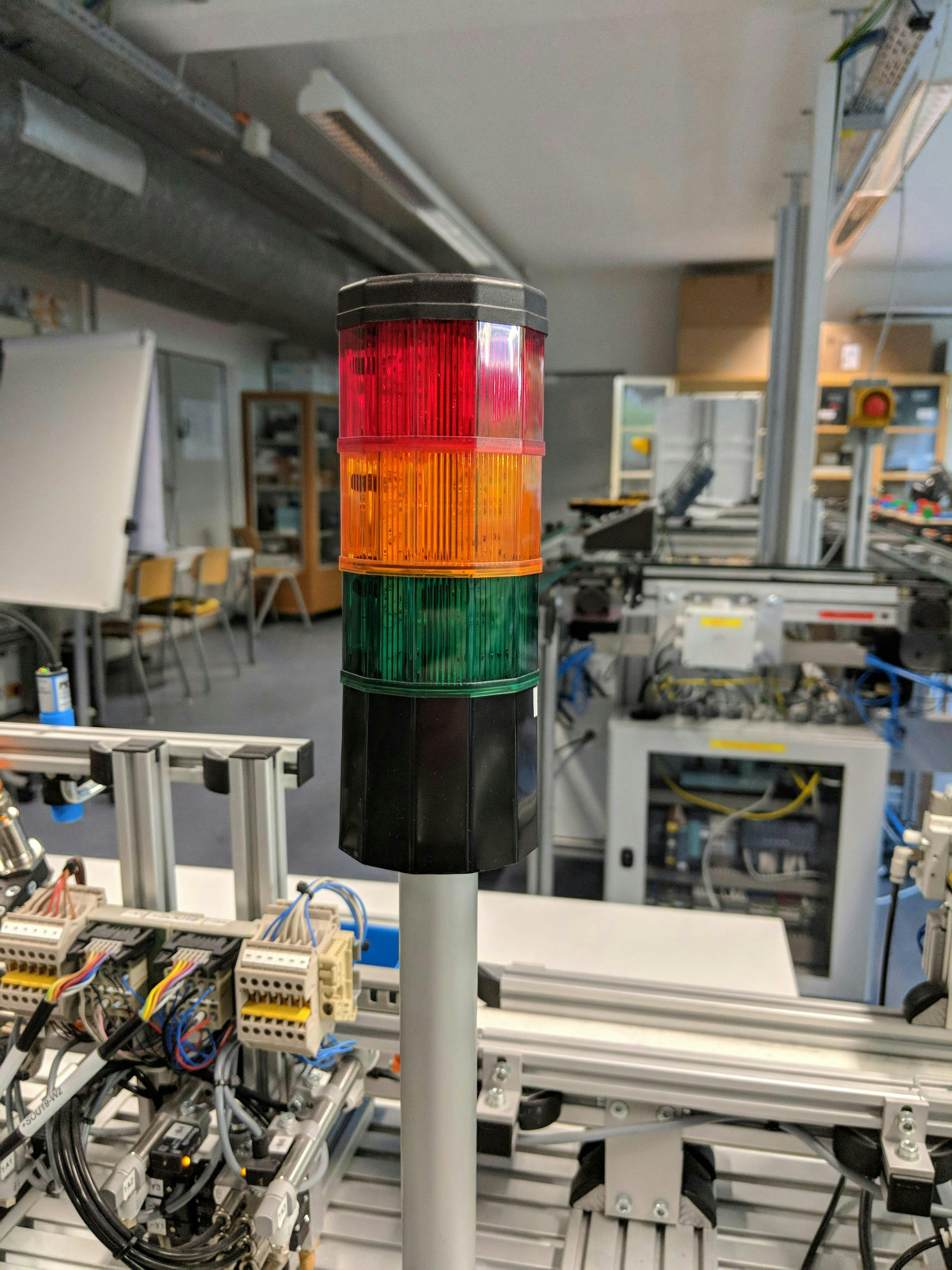

Another crucial factor to consider is color blindness. Approximately 8% of men and 0.5% of women are affected by color vision deficiencies, which can make it difficult for them to differentiate between certain colors (Figure 1). When too many colors are used on stacklights, individuals with color blindness may struggle to interpret the signals correctly, increasing the risk of accidents or machine malfunctions.

There have been real-world examples where confusing human-machine interfaces (HMIs) have led to fatal consequences. In some cases, the complexity and poor design of interfaces, including the misuse of colors, have been factors in accidents where operators failed to respond appropriately to critical situations. Simplifying the color schemes on stacklights, using well-established and universally recognized colors, such as red for stop, green for go and yellow for caution, can reduce confusion, improve safety and ensure that all operators, regardless of their color vision capabilities, can effectively manage machinery (Figure 2).

Jeromy Peterson, Owner and CEO / Ripple Industries, system integrator in Florence, Arizona, member of the Control System Integrators Association (CSIA)

Define your requirements

This is a good question, in that it seeks to keep functionality on task as a production tool.

Historically, indicator lights act as the first line of defense for operators to identify the state of a machine or process. Color coding makes the process state generically available right away, visible within a greater working area than an HMI, but with much less data. The “red bad, green good” color feedback is useful to plant-floor personnel as a starting point for operating their equipment.

Indicator-light color conditions are somewhat subjective. The standards agencies have touched a lot of what we do in automation but have just generically addressed indicator-light color coding. Referencing NFPA 79, Section 10.3.3, the use of color indication is quite open. In layman's terms, NFPA basically repeats the “red bad, green good” with yellow in the middle—more technically, yellow represents a warning condition. IEC 60073-2002 also addresses indicator color coding. You may find our information in our application guide for indicator lights useful.

In recent years, multi-color LEDs have become much more flexible to work with for designers. These LEDs have concurrently become more suitable for use in industrial environments. This is opening up possibilities for more functionality. More colors will be visible in industrial environments in the same form factors. Logic chips will add functionality and communications capacity.

So, this expands the application potential of a well-established automation component. This may add a layer of complexity or it may increase the net effect in the application of more colors, more patterns or more communications. Is that good or bad? Yes. It is both.

The base use of indicator lights will not change because they can do more. For most machines and audiences, including operators, production and technical personnel, the need to immediately know machine state, visible from a large area, will not change. Adding layers of complexity will diminish the result if the goal is simply to immediate display status. When operators cross-train on multiple machines in a facility that do different things, it is often a good strategy to keep the visual indication simple and generic across equipment—“green good, red bad”—so it’s meaning stays coherent from machine to machine.

However, there are instances where the device's enhanced functionality will increase the net result. Our experience with visual-communication products is that the best use of enhanced features is for very specific, defined requirements. Here are some examples.

Example 1, coil unwinder: Material feeding a long fabrication line comes off of a powered unwinder. The state of the material on the unwinder is well-defined. If there is plenty of material, the operator can tend to other areas of the line, such as the cut head area to collect processed parts. If the material runs out, the line makes nothing. If it’s low, the operator should start thinking about splicing or queuing up the next coil. A single segment multi-color indicator is well applied here. This is one that has only one color segment that can be any color the process requires. The state of the coil is an OR condition. If it's empty, a tangle is detected, or an e-stop violated, then the indicator turns red.

When the coil is low, it's yellow, looking for a splice or replacement soon. Green means all good—the line is making money. The operator can see it from up and down the entire line for immediate status.

Example 2, tank level: Tank level can be coarsely displayed visually with an indicator light. There are a few ways to do this. A five-color segment can be used to display low-low (red), low (yellow), acceptable level (green), high (yellow) and high-high (red) in the sequential segments top to bottom. It can also flash all segments red on a pump-failure condition.

These are useful, dedicated applications of enhanced features which should be well-received by users who understand the visual messaging of the process.

Communications is another layer of functionality that is expanding on visual communication components like stacklights. We see communications capabilities as quite useful; however, there are questions about what form that will take. Controlling an indicator light over a network reduces wiring and increases control capacity. Making the LED current draw data available over a network is useful to knowing if the unit is operating correctly. However, the machine's maintenance personnel might be better with a multimeter than with a computer when troubleshooting. It’s up to designers to evaluate what’s appropriate for the user relative to the ongoing ownership of the machine.

Let’s examine industrial communications protocols and then apply them to indicator lights. Industrial communications protocols require a large, slow-moving investment by the manufacturers developing them.

The protocols don’t always have staying power over time. The difficulty for designers is to decide which communications protocol to deploy. It must be technically suitable for the requirements. And, ideally, it will be around until after we retire. When a protocol loses staying power, that can leave a trail of machine longevity issues. Obsolescence is a very serious issue for machine ownership. Modbus, for example, has longevity built on a recipe of simple, reliable operation. Manufacturers can deploy it in products easily across multiple media. IO-Link is younger and is establishing itself. It’s at a different point in its lifecycle. EtherCAT and EtherNet I/P quickly found their place, mostly on the back of improving motion control. Stacklights could live on any of them if the manufacturers offer those options. So, it’s more a matter of what the market has made available. We see the main reasons for network deployment as reducing wiring, adding flexibility for application specific requirements and monitoring performance or status information. It falls on the designer to decide if using a network makes sense over a hardwired deployment. Selecting a network requires thought about performance for all devices, cost of deployment and longevity of the machine (Figure 3).

The promises of single-pair Ethernet (SPE) could muddy the waters further in the not-too-distant future. As a media layer, SPE is, to an extent, protocol-agnostic. SPE can deploy systems with Profinet, EtherCAT, EtherNet I/P or Modbus TCP/IP, or a mix of them. We are watching its development closely.

Lee Clore, owner and controls designer / Onyx Industries

Keep traffic moving

Traditionally, specific colors in a tower light are customer-driven, based upon the application requirements. For many years green, amber/yellow and red were the preferred choices because their similitude to traffic-light signals, where green indicates machine is running fine, amber or yellow indicate that a certain condition is present but not intended to stop the machine, while red indicates that the machine is stopped due a fault condition.

By adding flashing effects to the same colors previously mentioned, the customer can signal more conditions to alert operators in the plant floor—flashing green could indicate machine starting and change to solid when machine has completed the starting cycle.

Up to a certain point, this color/pattern arrangement doesn’t create too much confusion for the operators due to its simplicity; however, the position of the colors is important to assist colorblind operators, while the frequency of the flashing effect should be observed so it does not affect photo epileptic operators either.

The versatility of a stacklight allows more machine conditions to be indicated by adding light modules with different colors if required, thus preventing the use of a second visual indication in the machine. In addition, some organizations have been recommending the implementation of certain color standards in the stacklight to enhance the comprehension of operators by having a common interpretation of the status of the machine—Pack ML introduced by OMAC—where the light color, function and pattern are standardized within the facility to minimize the risk of operator confusion.

It really comes to the application itself. While a standard tower-light arrangement can be enough to inform the operator of the status of a machine, the use of a smart tower light regardless of the communication technology, can bring additional benefits. Most of these devices can be configured to certain colors, functions or patterns, minimizing the number of part numbers to keep in inventory. Another inherent benefit of the use of a smart stacklight is the wiring reduction, which will translate to quick plug-and-play installation, commissioning and troubleshooting of the stacklight itself (Figure 4).

Compared to a standard tower light, a smart tower light provides the possibility to gather real-time data, measurements and diagnostics that can contribute to minimized downtime with proactive maintenance scheduling and increased productivity. In this case, most of the information will be consumed above the operator level.

Alvaro Sanchez, global product manager, signaling products / Rockwell Automation

Safe, efficient and better operations

Safety and communication are critical in an industrial environment, and tower lights have provided an efficient and intuitive means of communication for years. By providing immediate visual feedback, these lights contribute to a safer working environment by providing easy-to-understand information, like changes in machine status or emergency situations, even in noisy and busy environments. Smart tower lights are gaining popularity for connected systems, processes and machines, as they allow for different, more unique setups and quick configuration and give the user the ability to collect data in different ways.

These devices have evolved to offer new levels of customization, including flashing light patterns, different sounds and pre-recorded messages to help operators do their jobs better, more efficiently and, most important, more safely. By customizing these to your machines or to a user’s specific needs, you can ensure that they communicate that critical information where and when needed most, without confusing the operator.

Patrick Casey, offer manager, control & signaling / Schneider Electric

Align stacklights with alarm tones

The implementation of stacklights significantly improves visual communication by enhancing the clarity of system status and conditions. With the use of various colors and patterns, operators can quickly identify specific states such as warnings, faults or operational readiness of systems. However, introducing multiple colors and flashing patterns may lead to confusion if not implemented thoughtfully. Operators might become desensitized or misinterpret signals if these are not standardized across systems. Therefore, it is essential to ensure that each color and pattern has a distinct and clear meaning and is well-documented with easy access. Smart stacklights, equipped with advanced communication technologies, such as wireless connectivity (Wi-Fi) and various messaging protocols, such as Modbus or message queuing telemetry transport (MQTT), offer significant advantages for better connectivity and situational awareness.

An application of this can be in a control room with many operator consoles. The challenge of managing multiple alarm priority tones from different operator consoles can be overwhelming, especially when alarms of varying priorities sound simultaneously. To address this, it is recommended to use stacklights alongside a common alarm tone.

Each operator console can be fitted with a stacklight that displays the highest priority alarm received at that console at an instance. A unified tone can alert operators to the presence of an alarm, while the stacklight indicates which console requires attention. This system helps quickly identify the console in need, even if operators are not at their consoles. The operators can then more efficiently navigate the alarm HMI to identify and address alarms based on its priority. This approach not only improves response times but also reduces the nuisance caused by multiple annunciating alarm sounds from different consoles.

Johnson Varghese, systems consultant / Yokogawa

Smart stacklight highlights

Stacklights, or signal towers, have served as a fundamental visual indication method in industrial settings for decades. They provide operators with clear visual signals, even at long distances, to monitor machine status and processes. Traditionally, these lights have used a limited color palette such as green for regular operation, yellow for caution, red for emergencies, blue for maintenance and white for specific statuses.

However, implementing an expanded range of colors and patterns dramatically enhances the ability of stacklights to communicate a broader array of conditions and can help relieve visual signaling confusion when carefully applied. With the right options, stacklights convey more detailed information about machine statuses, warnings and operational states. By incorporating additional colors and dynamic lighting effects—such as blinking, flashing or rotating patterns—signals can draw immediate attention to urgent events.

This ability to catch the eye quickly ensures operators can respond more effectively and efficiently to critical situations (Figure 5). The added detail and projected urgency enhance overall safety and operational efficiency, making it easier for workers to understand and react to the communicated information.

These advancements ensure that the interaction between machines and operators is more straightforward, more detailed and more effective than ever before. The modern signal tower stands out with its improved performance, offering more colors, effects, and individuality. Incorporating dynamic lighting patterns further enhances its capability, ensuring that urgent events are unmistakably highlighted, ultimately leading to safer and more efficient industrial operations.

Lenny Filipkowski, product manager / AutomationDirect