Even as alternatives have been developed, mechanical components remain as much a part of the motion profile as speed and accuracy.

"Advanced mechanical motion control components working in unison with today's electronic controls offer this performance at a cost-effective price point, which maximizes customer value," says David Hein, vice president of engineering, Nexen Group (www.nexengroup.com).

John Pieri, product line manager, Thomson (www.thomsonlinear.com), illustrates how the technology remains the best choice in certain applications. "One example is electromechanical wrap spring and friction clutches and brakes, which are widely used as an alternative to leading-edge servo technology," says Pieri. "Clutches and brakes offer flexible or custom mounting, simple installation, high accuracy, low power draw and high torque per unit size, all at an inexpensive cost compared to servo technology. Servo technology is overkill for most motion applications, in that the complexity and cost far exceed the requirement."

George Edwards, chief engineer, Fabco-Air (www.fabco-air.com), agrees that simplicity and cost are major attributes of mechanical motion. "Most machine element motions follow fairly simple paths," he explains. "Pneumatic actuators can provide these motions for low initial cost and follow with easy, low-cost maintenance and service as well. Pneumatic force outputs can meet most application requirements, ranging from a few ounces to several tons using force-multiplying air cylinders."

Installation, operation and maintenance are more easily accomplished with mechanical motion components, too, says Bob Jeter, applications engineer, Amacoli (www.amacoil.com). "Mechanical components require little to no training and are easy to install and operate," he explains. "Electronics can be complex and require expert technical support, while setup for mechanical devices is generally intuitive and they are easy to fix, thereby reducing downtime."

Low backlash planetary and helical-bevel servo gear units have input speeds to 6000 rpm with 15 integer ratios from 3 to 100 and circumferential backlash as low as 1 arc/min. PSC, PSF and BSF gear units span ranges of 25–3000 Nm of torque in 18 different models with input adapters to accept most any servo motor or be mounted directly on SEW's dynamic synchronous DS, CM and CMP servo motors.

SEW Eurodrive

888/sew-3876

eLine ball rail and cam roller linear guide systems are available in sizes 15, 20, and 25 with single-piece rail lengths to 4 m. Users choose between accuracy classes N and E, with or without preload. Family of eLine products includes both styles of runner blocks, end seals and front lube units on standardized rails.

Bosch Rexroth

800/322-6724

PDP alternative to ball screws is made of two ground WMH pinions connected through a preload system to reduce rack-and-pinion mesh backlash. When mounted at the output flange of SRP, a high-tech planetary gearhead, PDP offers four different modules with straight or helical teeth, eight reduction ratios, angle-drive versions, two-output pinion diameters for each size, and an input interface in-line flange or with a 90° angle.

Andantex USA

800/713 6170

Eclipse spring-engaged, servo motor brakes have a split hub, zero backlash clamp collar for attachment to the servo motor shaft in a variety of input and output flange/shaft combinations. Torque ranges 2–125 Nm, with low inertia, high tensional rigidity with no system wind-up, integral flanges that adapt to any servo motor and mounting style and NEMA 23, 34 and 42 frame sizes.

Nexen Group

651/484-5900

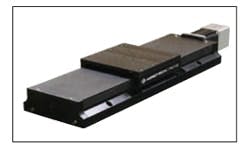

Pro Series ballscrew-driven linear stages in 68 standard models have travels of 50–1500 mm. The tabletop can be outfitted with an optional brush assembly and models are available with a 5 mm/rev, 20 mm/rev, or 25 mm/rev ballscrew with a matched brushless rotary servo motor to provide maximum travel speeds to 1400 mm/s with ±6 μm accuracy, ±1 μm bidirectional repeatability and up to 0.5 μm resolution.

Aerotech

412/967-6854

MDrive linear actuators with integrated step motor and driver technology come in three motor sizes and non-captive and external shaft styles, with options including programmable controller and motion control technology. These products have an input voltage range from +12 to +75 Vdc, nominal load limits of up to 200 lb and full (256 x 200) microstepping with an operating range of –40 to 85 °C.

Intelligent Motion Systems

860/295-6102

Nitra pneumatic line of stainless steel, round body, non-repairable cylinders feature type 304 stainless steel bodies with double rolled-in construction with high-strength aluminum alloy porting ends. Single and double acting models are available with nose, pivot and double-end mounting options. Some models are available with magnetic pistons for position indication. Bore sizes range 7/16–2 in.; depending on bore size; available stroke lengths range ½–18 in.

AutomationDirect

770/889-2858

SBK ball screw has a recirculation structure where balls are picked up in the tangential direction and the lead-angle direction by end caps. It has Caged Technology with a synthetic resin cage and patented curvature that cradles each ball and separates it from the next one. SBK is available with screw shaft outer diameters ranging 15–32 mm and nut diameters ranging 38–58 mm.

THK America

847/310-1111

Ultra Kleen right-angle, worm gear reducers are available in quill and three-piece coupled input and with solid or hollow output. Made of stainless steel for washdown protection, the units are available in ratios of 17, 21, 23, 26 and 30 with center distances 1.75-3 in., and a factory-filled H1 food-grade lubricant.

Baldor

479/414-4711

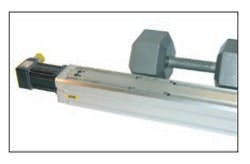

Electric actuator EGC is designed for high dynamic speeds and high rigidity. This modular actuator can be used as an individual component adapted to third-party motors or as a complete system provided by one source. The unit is available in toothed belt and ball screw designs, as well as different screw pitches.

Festo

631/404-3173

ZBX Series anti-backlash linear actuator assembly for vertical applications requiring noise or vibration control has a self-lubricating, polyacetal nut that is radially preloaded on a 303 stainless steel screw. The assembly offers torque consistency and repeatability when traversing in either direction through its unique load transfer capability.

HaydonKerk

800/243-2715

HD-N industrial-grade positioner offers bending moment of inertia for rigidity and minimal deflection, lubrication for life and maintenance-free bearings and ball screws. Positioners can come with custom motor mounts.

Parker Electromechanical Automation Div.

800/245-6903

Electric actuator EGC is designed for high dynamic speeds and high rigidity. This modular actuator can be used as an individual component adapted to third-party motors or as a complete system provided by one source. The unit is available in toothed belt and ball screw designs, as well as different screw pitches.

Festo

631/404-3173

ZBX Series anti-backlash linear actuator assembly for vertical applications requiring noise or vibration control has a self-lubricating, polyacetal nut that is radially preloaded on a 303 stainless steel screw. The assembly offers torque consistency and repeatability when traversing in either direction through its unique load transfer capability.

HaydonKerk

800/243-2715

HD-N industrial-grade positioner offers bending moment of inertia for rigidity and minimal deflection, lubrication for life and maintenance-free bearings and ball screws. Positioners can come with custom motor mounts.

Parker Electromechanical Automation Div.

800/245-6903

DM2 Series E Crossflow Serpar double valves are designed with total dynamic monitoring and memory for Category-4 machine-guarding applications. They are available in nominal size 2 with port sizes ¼ and 3/8, NPT and BSPP threads. The pneumatic safety-related valves address ANSI standards for machine safety, including the Z244 (lock-out), B11.19 (machine guarding) and B155 (packaging machinery).

Ross Controls

248/764-1800

Single-rail positioning stages have a small footprint, offer a speed of 6 m/sec, high acceleration to 12 g, zero cogging, resolution to 0.1 μm, repeatability to ±1 μm and load capacity to 25 kg. The stages are designed for applications requiring high acceleration, high accuracy and repeatability, such as high precision printing, Y-axis for pick-and-place equipment and robotics, vision inspection and parts transfer.

H2W Technologies

888/702-0540

Sponsored Recommendations

Leaders relevant to this article: