I/O Built for Flexibility, Scalability, Auto-Configuration, Compatibility and Reliability

Flexibility, scalability, auto-configuration, compatibility and reliability all play into machine builders' choices and uses of I/O components.

As systems become obsolete or reach capacity, new I/O must have the flexibility to connect for efficient real-time data exchange without replacing the outdated I/O or installing expensive customized interfaces, says Charlie Norz, product manager—Wago-I/O-System, Wago (www.wago.us). "Open standard protocols enable I/O systems to interface directly with most existing systems, and there are options available, depending upon company standards or regional conventions," he says. "I/O devices need to be network-independent to maximize efficiency and reduce system costs."

Beckhoff sees scalability as a critical feature of an I/O system. "One way to look at scalability is to have one I/O system that can be used as local I/O but is also capable of being distributed easily," explains Graham Harris, president, Beckhoff Automation (www.beckhoff.com). "This reduces the extra costs and effort associated with having different I/O systems for each application. The other criterion for scalability is whether the I/O system can be used in small I/O counts or large ones and can be specified to an exact I/O point count." The small counts can save considerable cost and labor when compared with I/O designs that only come in large blocks of eight or 16 channels and given that small I/O count PLCs often need a different I/O system than large PLCs, he says.

Many machine builders would count automatic configuration or automatic addressing as aspects of ease of setup and installation, says Richard Jackson, product marketing specialist, Omron Electronics (www.omron247.com). "Self-registering remote I/O reduces setting errors and can shorten production changeover significantly for machinery that has optional processing units for flexibility in manufacturing," he explains. "Once the smart I/O on a unit are connected to the main machine, it auto-registers not just the I/O but the unit itself. An example typical in printing operations are the interchangeable finishing units for folding, stitching and adhesive application."

Compatibility with existing systems allows users to connect new I/O devices directly to their existing network infrastructure, explains Stephen Arnold, senior automation product marketing specialist—automation products, Schneider Electric (www.us.schneider-electric.com). "Not only does this simplify installation and maintenance, it also reduces the cost to purchase and own your system by eliminating the need for network gateways," he says. "Gateways add cost, complexity and an additional point of failure to any solution. Choosing I/O that is compatible with multiple products and product types can further enhance this value, particularly if these products provide the flexibility to choose your specific level of sophistication based on the need of the application or machine." Some new I/O allow the user to choose an HMI controller or PLC solution and still utilize the same I/O across the application, says Arnold.

Susanne Walker, product manager—advanced connectivity, Weidmüller North America (www.weidmuller.com), agrees that compatibility must be considered. "In selecting I/O interface devices that are certified and tested by organizations and associations such as ODVA for DeviceNet and other CIP-based components, companies can ensure that the different components in their multi-vendor network systems can be installed easily and quickly and communicate properly with each other," she says. "This saves time and cost in installation and maintenance, optimizes machine up-time and assures the quality of the end product."

With regard to reliability, engineers often require more than just good manufacturing quality and MTBF rates, says Donald Lupo, director of sales & marketing—process, Acromag (www.acromag.com). "They need ‘survivability' to withstand a variety of environmental concerns such as extreme operating temperatures, RFI, EMI, electrical transients/surges, shock, vibration and location in potentially hazardous areas," he says. "The system architecture may also require redundant communications, power or even I/O to increase system reliability. In the event a failure occurs, engineers need features to help switch over or shut down the system in a safe, predictable manner."

Chris Vitale, senior product manager—network and interface, Turck (www.turck.com), agrees that reliability is the most important feature. "If a plant's I/O is not working, neither is the machine or system," says Vitale. "This will lead to downtime, repair costs, faulty end products and, worst of all, lost productivity. To increase reliability, I/O devices must be made with components that can withstand the harsh, industrial environment that they are installed in."

Like good health, reliability is the underpinning of any well functioning system, adds Bill McGovern, national sales manager, Dataforth (www.dataforth.com). "That's why we consider reliability the most important consideration for I/O devices or any product, and it's why we've worked hard to achieve a DPMO (defects per million opportunities) rate for our signal conditioners that is better than Six Sigma," he says. "What good is compatibility with an existing system or ease of setup and installation if the product is prone to failure?"

While the connector can feature everything from compatibility to superior setup and installation, scalability, density, power/signal and hot-swap capability, if the connector fails to perform, all of these features become a moot point, explains Chris Tubbs, assistant product manager, Hirose Electric (www.hirose-connectors.com). "Connectors designed for industrial I/O applications should meet appropriate water/moisture resistance, shock, vibration and gas-tight specifications," says Tubbs.

"Reliability finishes at the top of this list of most important features," says Ben Orchard, application engineer at Opto 22 (www.opto22.com). "It's a quality all of us look for in anything we purchase and use. For industrial OEMs and machine builders in particular, it's doubly important, as the goal for them is to ship their machine out the door and never have to see or hear about it again because it, and the I/O embedded in it, performs reliably for the customer with absolutely zero issues."

MIX-AND-MATCH MODULESLB/FB Remote I/O systems with redundant communication interface and power supply, connect to Profibus-DP, Modbus and Foundation fieldbus for discrete, analog, frequency and temperature signals. With LB systems, intrinsically safe (IS) and general-purpose modules can be mixed and matched on the same backplane. With FB systems, IS and increased safety modules can be mixed and matched on the same backplane. Pepperl+Fuchs330/486-0002

MEASUREMENT MODULESnap-AIPM-3 analog input module measures and manages three-phase ac power usage, mounts on an I/O rack and measures Vac rms and Aac rms. The module calculates true power, Volt-Amps and power sums for all three phases of power. When used with a Snap PAC R-series controller or Snap I/O brain, it can supports controlling and regulating equipment and facility power monitoring.Opto 22951/695-3000

724/775-7926

RFID SLICERFID-S slice for BL20 modular I/O system contains two channels. Additional RFID slices, as well as traditional discrete and analog I/O slices, can be combined on the same network node without special software for integration into a PLC system. Designed with digitized communication, it allows a 50 m separation between the transceiver and slice without noise induction, and all RFID channels operate in parallel.Turck800/544-7769

CONNECTION AND CABLENetBloc line of 11 networking terminal units provide connection and cable management on 35-mm DIN rails. The line includes standard RJ45-to-RJ45 couplers, RJ45 A-coded, RJ45 B-coded and RJ45 Profinet. Fiberoptic versions include SC single mode, SC multimode, ST single mode, ST multimode, LC Duplex single mode and LC Duplex multimode. Each NetBloc includes earth-grounding option.Weidmüller804/794-2877

PE FOOT INTEGRATEDScrew-connection terminal blocks with integrated PE foot available in 6.2 mm versions of the UT 4 knife disconnect, diode and fuse terminal blocks, provide options to disconnect or use a universal lever-style fuse holder for 5x20 plugs with or without light indication. UT 4-PE series provides termination for grounding shields commonly used in shielded twisted-pair wires for analog and digital sensors. Uniform dual-bridge channel delivers power distribution with FBS push-in jumpers. Phoenix Contact800/332-3225

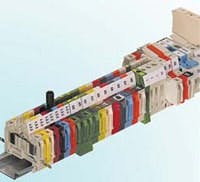

TOPJOB LINETopjob S line has 24 disconnect, diode and LED terminal blocks. Specialty feed-through blocks accommodate conductors AWG 22–12 and are available in two-, three- or four-pole variants with single-, double- or triple-deck configurations. Each DIN-rail mount block has a staggered jumpering system for potential commoning and traditional push-in jumpers. Disconnect terminal blocks feature a test plug located on the side of each knife disconnect. The specialty blocks employ push-in terminations for ferruled or solid conductors.Wago800/din-rail

Simatic ET 200pro IWLAN delivers wireless connectivity from any distributed I/O station. Based on IEEE 802.11 WLAN standards, the wireless design supports deterministic industrial point coordination function (iPCF) for critical industrial Ethernet communications using standard Profinet protocol. Wireless radio frequency is selectable for either standard 2.4 GHz or 5 GHz and includes support for IEEE 802.11 a/b/g/h/e/i transmission standards. The maximum wireless data transmission rate is 54 Mbits/sec with a typical send cycle time of 32 msec.

Siemens Energy & Automation

800/241-4463

888/385-1221

SAFETY I/O TERMINALSDST1-XD0808SL-1 safety I/O terminals support six safety inputs and eight safety outputs and can store simple logic. This allows local outputs to be directly controlled by local inputs with a maximum response time of 18.7 msec. The I/O terminals safely move a machine to a safe state regardless of network structure, number of I/O modules or overall program complexity.Omron Scientific Technologies510/608-3400

SMART I/OSmart Remote I/O Adapter includes a three-port managed Ethernet switch and embedded firewall, and it can optionally be equipped with a fiberoptic interface or phone modem interface to eliminate supplemental equipment such as switches or media converters. Adapter holds three modules or connects to up to 12 locally connected racks. All local I/O can be scanned in less than 1 msec. Five RS-232 serial ports and one optional RS-485 port can remotely interface to serial devices.SoftPLC800/softplc

Continue Reading

Leaders relevant to this article: