An overview of some of the packages currently available for monitoring or managing industrial networks follows. This is by no means a comprehensive list.

Phoenix Contact (phoenixcon.com) supplies managed and unmanaged industrial Ethernet switches. The company’s Factory Manager configuration and diagnostics software package can be used with any vendor’s managed switches. The company says Factory Manager is designed to make it quicker and easier for people who are not necessarily network experts to implement and maintain Ethernet networks using SNMP network management and diagnostic functions.

“Factory Manager has full IT features but is set up in a manner that is useful for plant engineers and operational and maintenance people,” comments Phoenix Contact’s Ken Austin. “Instead of just limiting itself to diagnostic functions, Factory Manager provides a complete product set for everything from configuring and starting up network devices right through day-to-day operations.”

Familiar Microsoft Windows-based software provides the user with an overview of the network devices. A network scanner sends scans out over the network to monitor the health of network devices and an SNMP trap receiver communicates the diagnostic messages back to the host PC. Alarms and events are alarmed on the PC.

Enterasys NetSight Policy Control Console

NetSight is designed to enable an organization to manage its network as a whole, rather than a disparate set of devices.

SOURCE: Enterasys

Enterasys Networks (enterasys.com) offers NetSight management software suite, designed to enable heterogeneous networks to be managed as a whole, rather than as individual devices. It works with SNMP-enabled switches from Enterasys and other companies. Enterasys recently introduced a line of managed switches designed specifically for demanding industrial applications and has gained a good understanding of the industrial world through its partnership with several automation vendors.

While NetSight is designed for use by IT people, the NetSight Console user interface offers a simple, pushbutton web interface for plant personnel. The web interface allows plant personnel to make temporary policy changes, launch diagnostic routines, force failover to another path around the ring, and run manual recovery routines, as needed. It also allows real-time monitoring of traffic on the network.

“The advantage of the NetSight offering is that it masks the complexity to allow you to manage the network as a whole,” comments Trent Waterhouse, vice president of marketing at Enterasys.

NetworkVision IntraVUE

IntraVUE software automatically discovers all the devices on the network and then automatically maps their connections.

SOURCE: Network Vision

A major automobile manufacturer is deploying Ethernet across all its new plants globally. “We’ve set up our industrial manufacturing networks to be a logical extension of our IT networks,” reports an engineer responsible for manufacturing networking strategies at this company. “Our IT people use HP OpenView to manage the overall network, and they’re very comfortable with this. However, there never was an effective interface from the plant floor into the IT management console and therefore no way to get information to the plant floor in a timely manner. We’re supplementing the IT group’s commercial network management system with IntraVue at the plant level.

Cisco Network Assistant

Network Assistant, Cisco’s management package for smaller networks, provides a centralized network view through a user-friendly GUI.

SOURCE: Cisco Systems

A major North American forest products company has standardized on Cisco switches and software for its corporate networks. According to a process control engineer at the company’s central research and development center, these require more IT skill than is available at the plant level. “We’ve deployed IntraVue at a few of our manufacturing locations. It lets us easily map the process control networks and provide a status of the links so we can understand the traffic and performance of our networks.”

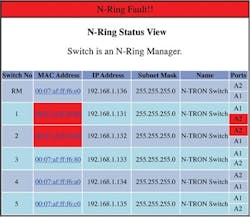

N-TRON N-View

N-View OPC variables are presented to the OPC client as string variables, which most HMI software packages can covert into the appropriate data type required for display alarming, and trending.

SOURCE: N-TRON

Cisco Systems (cisco.com) has a major presence in enterprise networks. As evidenced by the recent partnership announcement with Rockwell Automation, the company is paying increasing attention to networking issues on the factory or plant floor.

Cisco doesn’t offer an industrial network management package. However, the company’s CiscoWorks suite, which is somewhat a standard for managing enterprise-scale Cisco networks, can be used by those IT people charged with providing second-level support for larger industrial networks. This provides comprehensive configuration, administration, monitoring and troubleshooting for Cisco networks.

The company also offers Network Assistant, a simpler, no-cost, PC-based network-management application for smaller Cisco local area networks. This could provide a basic monitoring and management solution for networks in many small-to-medium size process plants or factories with some dedicated IT support staff. Both CiscoWorks and Network Assistant are complementary with many industrial network management packages.