CLPA companion specification integrates into OPC UA technology

As described by the OPCF, OPC UA (Unified Architecture) is a platform-independent, service-oriented architecture that integrates the functionalities of the individual OPC Classic specifications into one extensible framework. It delivers the necessary infrastructure for interoperability and for moving data and information from the embedded world to the cloud. It also addresses cybersecurity with technology that has been assessed by the German Federal Office for Information Security (BSI).

"With Industry 4.0 becoming a key topic, this companion specification will increase process and system transparency for end users, enabling more efficient operations, better product quality and higher productivity," said John Browett, CLPA-Europe general manager.

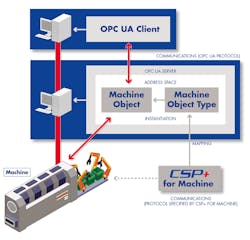

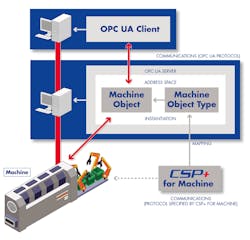

CLPA’s activity with the OPCF aims to expand its existing CSP+ (Control & Communication System Profile) technology from describing individual devices to apply it to complete machines and production lines. This is the key concept behind CSP+ for Machine.

The new CSP+ for Machine extension of CSP+ provides offers profiles that describe whole machines instead of just devices on a CC-Link IE network.

"The CSP+ concept has allowed individual devices on a network to be defined by a profile and, therefore made it easier to configure and maintain networks. By mapping the OPC UA model to CSP+ for Machine, we can take a step further and offer the ability to treat an entire machine like a device," said Browett. "Thus, we simplify configuration and maintenance on a much higher level."

Via XML, CSP+ for Machine provides information concerning machine specifications, application software, data to be acquired and how, as well as relationship between machine data and information.