Relying on a distributor for multiple brands of controls automation has its many advantages and disadvantages. Is it better for your automation distributor to have expertise with a single supplier, or are you better off turning to a distributor that is vendor-agnostic?

“Many high-tech distributors that carry controls often can support multiple product brands with similar performance characteristics,” explains Bob White, technical sales manager, Nippon Pulse. “However, it can be a challenge for a customer to simply interchange brands based on the technical nuances related to interfaces or programming environment. From a manufacturing perspective, having a business continuity plan in place which identifies and qualifies multiple vendors for key components is important. Also, having a global footprint with the ability to shift manufacturing locations quickly can smooth out any issues with local suppliers that may occur. With this new backlog of delays in product availability and the past trends of distribution acting more as a sales channel rather than a stocking distribution model, customers are finding themselves in trouble.” This is a new opportunity for distribution companies to begin to get more involved in the long-term forecasting of order flow and stock product as a part of that planning, says White.

Also read: COVID-19 pandemic impacts supply chain, Industry 4.0 and 5G

“While our distributors typically carry our products in their automation portfolio, we also recognize that our portfolio may not cover all applications,” explains Lance Fuhr, director of channel excellence, Honeywell Process Solutions. “When selecting channel partners, we also look closely at their complementing lines, so that they can provide the full scope of automation offerings to our mutual customers.”

There’s no one manufacturer in the automation business that offers everything, especially when you consider how many different types of controls, sensors and protocols there are, explains Eric Wendt, director of automation and electrical products for Digi-Key Electronics, which offers many different brands and products, some complementary and some competitive. “Some customers may design automation products, all on a specific brand platform, while others may use many different brands for different things,” he says. “Then there are the ancillary, but necessary, products such as wire, wire duct and interconnect. Purchasing from a distributor gives you the ability to order everything in the same cart.”

The potential disadvantage to purchasing from a distributor is potentially having access to a lower level of technical ability than the manufacturer might have about their products, warns Wendt, who recommends a high-service distributor with strong technical teams that can provide technical specifications directly from manufacturers for each component.

“The right distributor will provide customers with choice when it comes to the solutions they are seeking to design, build or maintain,” says Ken Bradley, president, Allied Electronics & Automation, who notes additional advantages provided by distributors:

- showcase all of the latest innovations from the major players in the market for the customer to choose from

- leverage the strengths from all of the individual brands and combining them into the best solution for the application

- provide multiple options for stock availability when supply chain challenges arise.

Figure 2: One disadvantage of carrying multiple brands might include a dilution of or lack of technical expertise across so many lines.

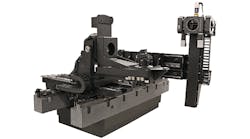

“Distributors are generally healthier and can weather larger storms when they are diversified,” says Brian O’Connor, vice president, marketing, Aerotech. A disadvantage is that their inventory levels for one type of brand and/or product may be smaller because they have diversified inventory levels, explains O’Connor (Figure 1).

An advantage of a distributor stocking multiple brands of similar products is the ability to cross over parts based on availability, explains Arun Sinha, director of business development, Opto 22. “This works for commodity products like relays, controls and some instrumentation,” he says. “However, automation products are increasingly more of an engineered solution, and, possibly with the exception of simple fixed I/O PLCs, there are more factors to consider like programming environment, protocol support and advanced functionality that may not be interchangeable.”

One disadvantage of carrying multiple brands might include a dilution of or lack of technical expertise across so many lines, says Sinha (Figure 2). “At Opto 22, we pride ourselves on technical expertise, so we seek out distributors who have it and work with others to make sure they get there,” he explains.

What became increasingly clear in 2021 was that distributors that only sell a single HMI or PLC brand faced a tougher time meeting the needs of their customers, says Brian Jaeger, technical content developer, Maple Systems. “With the increasing interconnected nature of controls, what we are seeing now is that for many new customers, application customization is where the value lies,” he explains (Figure 3).

Figure 3: Distributors that only sell a single HMI or PLC brand faced a tougher time meeting the needs of their customers.

“Distributors that carry competing control lines are often caught in a tug of war between suppliers, which makes it tough for them to get the volume and market share that each supplier would like,” says Jon Towslee, senior director of iFactory sales, Advantech. “However, we see much greater upside when distributors carry multiple brands of complementary control components. These complementary lines often open doors to new customers, new applications and new industries. Selling with our distributors, we are often able to understand end customer needs in a deep and meaningful way, such that we generate new opportunities for us and our distributors.”

One advantage of relying on a distributor is that, if one brand is experiencing delays, the distributor is familiar with the needs of the end users and can help make the switch to another controls brand, says Freeman Smith, founder, Nufactur. “The disadvantage is that this is better in theory than in practice,” he cautions. “Distributors typically feel more comfortable with one control system and will not be able to provide the same level of expertise in a different communication protocol. Furthermore, end users rarely can just swap out their controls systems to a different protocol. If that is the case, it makes more sense to go with a distributor who is laser-focused on one specific brand of controls automation.”

The advantage of relying on a distributor for multiple brands of controls automation is that you reach your local market faster and more efficiently, explains Kristian Hulgard, general manager, Americas, OnRobot. “Most industrial manufacturers do not have the capacity to sell, support and service their products to the end users in all their local markets; this is where distribution has its advantage,” he says. “One disadvantage is of course that you share the distributor’s mindshare with other, potentially competing, product lines. What we do to mitigate this is invest a lot of time and resources into educating our sales channel on when and where OnRobot products make sense to offer.”

Hulgard predicts more application kits in the marketplace in 2022. “Instead of users having to piece together a robotic application from many different sources, wondering about compatibility, proven track records and total cost of ownership, they increasingly look to application kits offering a plug-and-produce setup with all components validated to work together from Day 1,” he explains.

Customers can find multiple solutions and a lot of information to consider for their solutions when they rely on a distributor for multiple brands of controls automation, says Tim Fredricks, channel sales manager, Advantech. “The downside is that we may lose an order based on price or lead time,” he explains.

“An advantage of relying upon a distributor for multiple brands of controls automation is primarily local support and local value-add services,” explains Brandon Ellis, owner and president of elliTek.

For elliTek, that means a full staff of applications engineers trained on products and ready to meet our customers where they are. Additionally, elliTek’s dedicated training center allows customers to receive factory-grade training while staying local and avoiding high transportation costs and easing contagion concerns, says Ellis.

“We also maintain stock for many of our high-volume and hard-to-find items, although the supply-chain crisis has left shelves emptier than normal,” continues Ellis. “Thorough technical knowledge of our various product lines has proven invaluable for end users of late, as we work to create creative solutions where the typical solutions have become impractical due to the lack of available products.”

Figure 4: There’s an advantage to the end user by offering up an ecosystem of third-party peripherals certified to work seamlessly with one another.

With Universal Robots offering up an ecosystem of third-party peripherals certified to work seamlessly with UR cobots, there's an advantage for the end user in choosing a distributor that carries not only UR cobots, but also a wide portfolio of UR+ certified products, explains Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots. “The UR+ platform now encompasses more than 300 different companies offering close to 380 products and application kits certified for plug-and-play use with our cobots,” he says (Figure 4). “The vast majority of our distributors carry their choice of UR+ products that they will include in application specs. It's really a win-win for both the end user, the distributor, the UR+ partner and Universal Robots.”

The primary advantage of relying on a distributor for multiple brands of controls automation is the multiple options it yields, says Jeff Mahler, co-founder and CTO at Ambi Robotics. “A distributor can act as a third party with an independent assessment of different options,” he explains (Figure 5). “The main disadvantage is that it can be harder to receive the benefits of working directly with the vendor, such as reduced pricing and advanced features.”

When the supply chain crisis hit, Ambi Robotics leveraged its distributor network and vendor network to ensure its needs were covered. “Having good relationships with vendors is really important because they will work with us directly to monitor stock levels of certain critical components,” explains Mahler. “It is harder for us, as a system producer, to have that level of knowledge within the vendor’s real-time production.”

Figure 5: The primary advantage of relying on a distributor for multiple brands of controls automation is the multiple options it yields.

For distributors to be successful, it’s essential they understand the latest and greatest solutions available to present them to customers, explains Aric Prost, senior global director OEM at Stratus Technologies. “In turn, organizations therefore look to the distributors to recommend technology that will improve efficiency and productivity,” he says. “By sourcing control solutions from multiple distributors, system integrators, for example, are able to build bespoke solutions for end users and incorporate best-of-breed approaches. The drawback is the time involved to synchronize ordering, calculate sizing, engineer the solution and conduct validation testing.”

Working with distributors, Stratus Technologies has addressed this advantage/disadvantage by developing pre-validated architectures that combine its platforms with micro data center enclosures and uninterrupted power available in a range of pre-engineered configuration, says Prost.

“For the customer, there are several advantages of one distributor offering multiple brands: one throat to choke, transactional efficiencies and alternatives/options in troubling supply chain times,” says John MacDougall, manager of industrial channel sales, Phoenix Contact USA. “There are advantages for the manufacturer, too, the main one being the distributor’s ability to bundle products from multiple manufacturers to provide a complete solution. The individual manufacturer may benefit from that collaboration and get more opportunities than they would have alone.”

From the customer’s perspective, one purchase order (PO), or one transaction, can provide a variety of manufacturer’s products. Also, depending on the distributor’s in-house resources, the customer can have a single point of contact to support multiple manufacturer’s products, explains MacDougall. “Conversely, most manufacturers would rather be the only option on the distributor’s line card for any specific product or technology,” he says. “Manufacturers would rather not have to compete with other manufacturers on the distributor’s line card. The distribution channel often takes a best-in-class strategy and picks and chooses automation/control components that they feel most comfortable with and ones that provide the best solution for customers’ application needs.”

Distributors are masters of receiving, storing and distributing products and parts, effectively managing the middle of the logistics chain by predicting and planning demand, says Jim Wilmot, manager, Simatic PLC products, Factory Automation business unit, Siemens Industry. “This can help streamline logistics for companies without the ability to build their own supply chains from scratch,” he explains.

“Distributors do come with drawbacks,” warns Wilmot. “If they do a poor job predicting demand, you can have significant supply issues. You may be placed on allocation and only receive some small fraction of what you need as the distributor manages scarcity by spreading the available components around between customers. Distributors can also act as the arbiter of what components you can use because they only carry certain brands or product lines.”

Relying on specific control automation many times locks the manufacturers into specific vendors, making the systems rigid and the changes hard to adopt, says James Zhang, vice president of market development and connected operations at PTC. “Those are two major disadvantages we observed from our own customers,” he explains. “The industry is working to address these challenges.”

One example from PTC customers is a flexible manufacturing model, otherwise known as modular manufacturing, says Zhang. “In Europe, there’s an emerging open standard known as module type package (MTP), and it is a game-changer for flexibility,” he explains. “MTP enables automation of process modules—boosting production flexibility and improving project engineering loads, time to operational readiness, affiliated costs and time to market.”

Evonik is a large specialty chemical company in Europe, and it’s working to become independent of specific automation vendors and technologies, says Zhang. “With MTP, Evonik is able to avoid being locked into any one particular vendor,” he explains. “With this effort, the user interface is easy to install and use, the modules can be interchanged, and MTP can be applied wherever beneficial. These benefits can be further amplified with IIoT-enabled process orchestration. By adopting MTP and by using IIoT data to orchestrate processes, manufacturers are becoming more flexible, scalable and resilient, attributes that are more important than ever during today’s turbulent market conditions.”