Q: The supply-chain woes caused by the global pandemic have changed the way that machine builders manage their materials inventories. How has MISUMI addressed ordering, shipping and fulfillment needs of its customers?

A: MISUMI has always been focused on our customers’ time value, committing to reliable, quick delivery and reducing customers’ wasted work and tasks. Our unique business model combines both a manufacturing business that makes and sells components as well as die sets and a distribution business that stocks and sells a wide range of top third-party brands’ parts and consumables for industrial automation, allowing MISUMI to be a one-stop shop for customers (Figure 1).

Through the MISUMI website, customers can quickly find the quality components they need at low costs from top brands. We offer over 20 million parts from more than 3,000 brands with same-day shipping on over 100,000 stocked parts. Seventy percent of our products ship in four days or less.

MISUMI’s online configurator allows customers to easily configure parts with dimensions up to a micron, accounting for 80 sextillion—80 billion x 1 trillion—configurations. Customers can select the part, shape and dimensions needed, and the configurator will instantly generate a part number, pricing and lead time, eliminating the time wasted on waiting on a quote for a custom drawing. Computer-aided design (CAD) models are also available after configuration.

Q: On a related note, with machine builders often looking to place smaller orders with the same benefits of volume ordering, how have you accommodated those requests?

A: MISUMI is focused on saving customers' time. Nearly all of our components do not require any minimum order quantities, and our configurator provides pricing at various quantity breakdowns with quick and reliable shipping.

Every customer order is treated the same, and the first order received will be the first order shipped. All customers have access to our technical support engineers when they need it.

Q: Some machine builders are looking upstream in the supply chain for parts and components that are customized and configured for their needs. What kind of services can help to minimize engineers' pain points when it comes to cable or enclosures or other products?

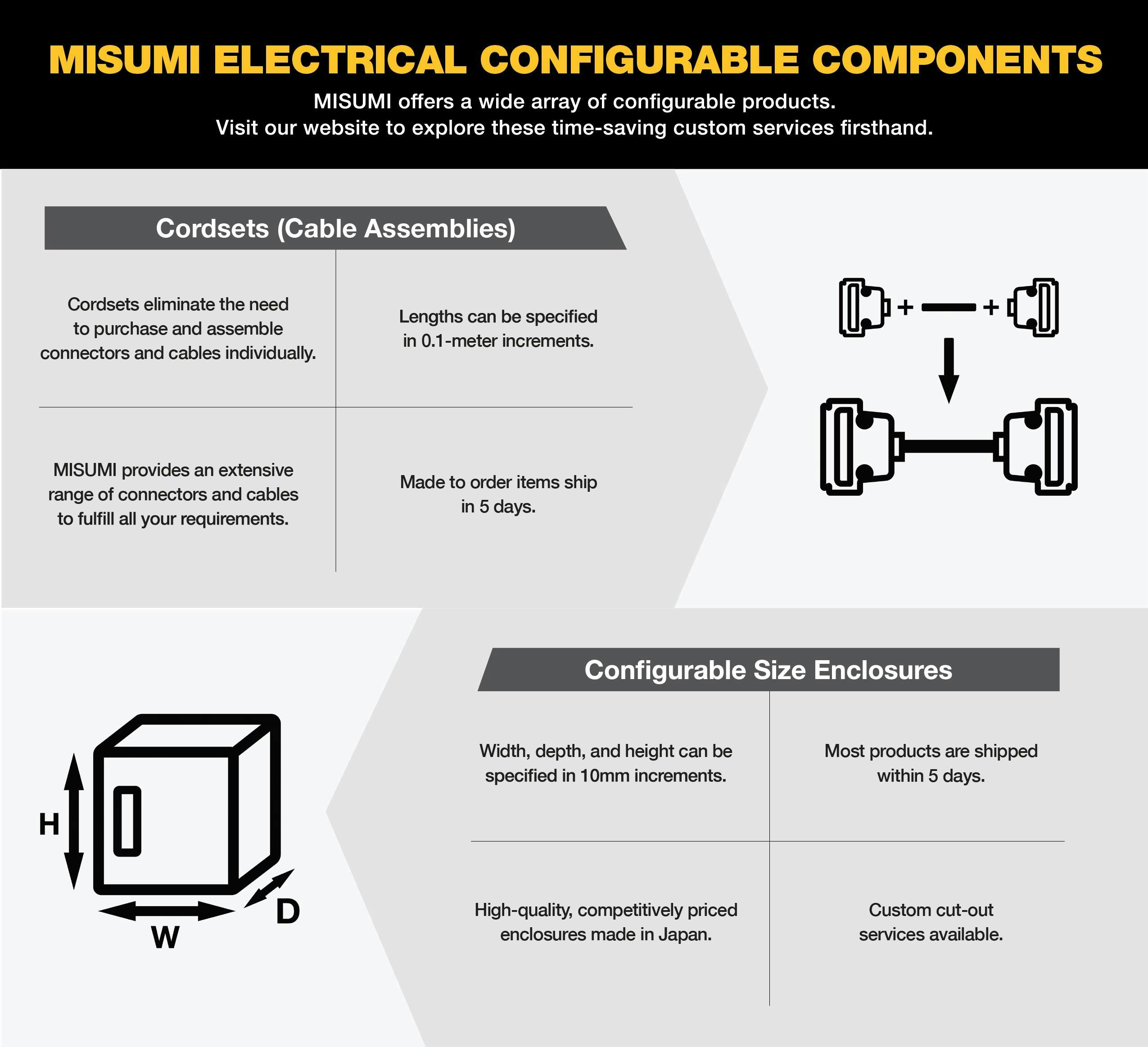

A: Along with MISUMI’s 80 sextillion configurable components, we recognized that we could offer other services to reduce the customers in-house tasks, saving them time. Therefore, our Industrial Electronics team has developed programs for cut-to-length cabling, customized electrical enclosures and custom cable assemblies, all available with no minimum order quantities (Figure 2).

We also provide quality and cost-effective custom cable assemblies with a quick turnaround time. We specialize in one piece to a few hundred in quantity and customers will receive their cable assembly within four weeks, including the quotation process.

These services are again part of the time value we offer our customers. By outsourcing these needs, companies can shift their staff’s work to more valuable tasks.

Q: Time is money. What are some strategies machine builders can employ to reduce time to market and ensure a swifter build process?

A: Machine builders are natural problem solvers, and we believe that one strategy for them is to lean on their supplier partner for solutions. Suppliers are experts in their products and can be creative in the ways their products can be used in various applications. Sometimes a new perspective is needed or a supplier can unveil a product that can solve a builder’s problems.

Q: Where is the sweet spot for MISUMI and its ability to help machine builders obtain the products they need to optimize design and build and maximize profitability?

A: MISUMI's sweet spot lies in our ability to support small and mid-sized orders for both mechanical and electrical components. Our manufacturing business’ unique method of standardizing custom parts that would require sending drawings out for a quote allows machine builders to configure their part needs in minutes with our online configurator and instantly see pricing and lead times. Furthermore, we have over 20 million off-the-shelf components ready to ship with our distribution model. This combination of capabilities provides great time savings and the simplification of the procurement process to empower machine builders to source everything they need from one vendor—MISUMI.