Design conveyance first to minimize motion time and optimize process time

Conveyance is mistakenly an often-overlooked component in an automation system.

Why? To some, it simply moves parts from A to B, so it doesn’t need attention until later in the design phase when station designs are complete. Or some automation designers may think that it has a minimal impact on system performance, so it’s not important enough to give special consideration.

In some cases, those statements may be true, but it is very common, especially in assembly automation applications, that the diversity of requirements—station cycle times, precision, multiple part types—can make it very difficult to get a well-balanced system that produces a consistent number of parts.

Conveyors are like roads. Speed limits, lanes, traffic lights, accidents and construction all play a major role in determining how long it takes us to get to our destinations. We’ve all been stuck in traffic, grumbling, “I wish they would have designed this city better.” But most cities aren’t really designed with a clear end vision. There was an initial part and then over time new parts or roads were added as the population and the number of cars grew. It can be hard to manage efficiency when systems are designed in this manner, and it’s the same idea with conveyance.

You design a station and then add more stations. Then you’re forced to figure out how to get the parts between them. It may be okay initially, but, the more complex the system gets, the more conveyance plays a critical role in overall system performance and resulting costs.

There are three major factors that determine the capability of a conveyance technology within an application: speed, precision and flexibility.

Speed: Speed is important in applications that require faster cycle times. There is no value being added when the product is in motion or not at a station. By lean standards, this is essentially waste. It is better to get the product in and out of the station as fast as possible because when it is being “worked on” value is being added. More time in process. Less time in motion.

Precision: The assembly of a part requires a certain amount of precision. Picking and placing a gear, pressing a bushing, dispensing glue, fastening, inspection, testing, loading, unloading—each operation has a different requirement. Depending on the conveyance technology, you may need locate tooling to get the part into a repeatable window so the operation can be completed successfully.

Flexibility: When designing an automation system and selecting the technologies that will go into it, one of the biggest challenges an engineer will face is the amount of diversity in the system that they must account for. For example, there are challenges like diverse station cycle times where every process has a different time to completion; they are never the same. Or precision requirements when some processes need to place a part within a window of a few microns and another process is within a quarter of millimeter. Or the assembly sequence and the number of steps to completion may be different between part types. It never really ends. Luckily, flexibility, and in the case of conveyance, independent shuttle control, is the solution to diversity. The ability to independently control a shuttle on a conveyance platform means that you can balance these challenges much more easily.

Let’s look at some conveyance technology examples to illustrate the importance of these three factors.

The dial, or rotary indexing dial, is a go-to solution for many automation designers because it can be fast, precise and cost-effective. The dial is a rotating plate, or table, that indexes the product between each station. Speed and precision are the two factors that can be utilized here. The rotation can be controlled with a servo motor so the index can be fast, and tooling plates can be designed to house the product and maintain a tight repeatability. For applications with fewer stations and consistent cycle times, this is a very good solution. Designers will generally implement a “multi-up” operation, meaning that the stations will work on multiple parts at the same time. For example, if it takes two seconds to complete a process and you work on two parts (2-up) at the same time, you are essentially getting two parts in those two seconds. If you do 3-up, you are getting three parts in two seconds. Extra tooling is needed to work on multiple parts. And, to get a consistent system output—parts per minute—each station will need to produce at the same rate or less.

A pallet conveyor moves pallets or shuttles using a belt or chain. Stopper cylinders are used to stop the pallet at the station, and locate tooling may also be required to position the part into a repeatable window so the station tooling can do its work. For applications with slower cycle times, the pallet conveyor is a very common solution in industrial automation.

If you walk on any manufacturing floor, you are almost guaranteed to see several different versions of this technology. The pallet conveyor is asynchronous, so that means that each pallet’s motion is independent. If you have inconsistent station cycle times, you have the flexibility to move between 1-up and multi-up, so you only need to add station tooling to the slower processes. The faster stations can be left alone.

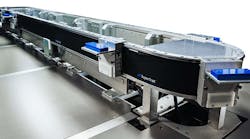

Balancing speed and precision with flexibility is a common requirement in automation system design. Smart-conveyance technologies are based on a linear motor design and include positional feedback like a servo motor; the system has independent control of each shuttle at all times (Figure 1). The system can have velocities of 4 m/s and accelerations up to 50 m/s2. It can also be incredibly precise with a repeatability of +/- 0.01 mm. Combine that with the ability to independently control the destination, velocity and acceleration of each shuttle, and the resulting flexibility enables system designers to meet performance requirements with less tooling in a smaller footprint.

Designing your automation system with smart conveyance can improve performance and reduce cost.

Asynchronous motion: When you have a slow station, you can implement multi-up. For fast stations, you can maintain 1-up, meaning you can go from multiple shuttles being worked on at a station to one shuttle at the next station. With smart conveyance, you can minimize tooling, which as a result, will also make the footprint smaller.

Independent shuttle control: The independent shuttle control available with smart-conveyance systems means you can utilize the conveyance as an axis of motion within the station design. You can use the shuttle itself for the required motion. That may mean moving forward or backward at different velocities and accelerations. Or it may mean coordinating motion with another axis. Overall, this means easier control of asynchronous motion and a better way to achieve high-performing automation in a smaller footprint (Figure 3).

More time in process, less in motion

Getting the shuttle into a station faster saves a lot on cycle time. Combining that with independent shuttle control means you can work on multiple parts on a shuttle shelf by indexing through the parts at a high acceleration under one piece of tooling. Often this meets cycle time requirements with significant savings on material costs.

When using synchronous conveyance, the station-to-station pitch, or distance between stations, is limited by the requirements of the widest station, which would then define the index distance on a dial. If other stations have a narrow profile and could be closer together, you end up losing floorspace because you cannot use the footprint effectively. With smart conveyance, you can re-pitch the distance between stations as often as is required due to its independent shuttle control.

With all the potential benefits in mind, the upfront material cost of a smart-conveyance system can be significantly higher, so to realize the value, the application must be properly validated. A go/no-go guide can be used to determine if an application is a good fit for smart conveyance. We look at three main factors.

1. Number of process steps: The more complex a system gets, the better suited it is for smart conveyance. More opportunities to remove tooling and reduce floorspace mean more cost savings. Generally, if the application has six or more process steps, or stations, it will be a good fit.

2. Cycle time requirements: To benefit from speed, you should have an application that needs to be fast. Cycle times of 8 seconds or less are the sweet spot for smart conveyance.

3. Repeatability: Any process that needs a repeatability of +/- 100 microns generally requires locate tooling before work can be performed. With smart conveyance, that is not required. The shuttle can come into position and the tooling can start working immediately.

Typically, if you have two of the three major factors in an application, the value of smart conveyance is realized.

We’ve seen success across a variety of industries, but, most commonly, smart conveyance offers return on investment (ROI) in automotive, including electric vehicles, consumer products manufacturing, medical devices and pharmaceuticals. It is in these industries where we usually see that smart conveyance solves common manufacturing challenges associated with high-volume assembly, limited floorspace, modularity requirements and energy efficiencies, to name a few.

There are also minor identifying factors that can add value to the automation system:

• Is the system going in a clean room? Smart-conveyance systems have very few moving parts, so particulate generation is low.

• Does the facility have a sound threshold? Smart-conveyance systems operate at very low sound levels, so hearing protection is not required.

• Is there more than one part type? Part changeover can be very straightforward because station stops and shuttle behavior can be re-configured easily due to independent shuttle control.

• Energy usage is also very important in manufacturing. Many smart-conveyance systems have simulation tools available where power can be modeled and optimized. This enables you to better utilize energy that contributes to productivity and minimize energy that does not.

Smart conveyance is not the best fit for every application, but when certain criteria are met, automation-system designers are able to maximize system performance requirements in a smaller space and at a reduced overall cost.

By starting an automation design with a focus on the conveyance technology, you are forced to define the process flow, which means you will better understand the performance required for each station. With this approach, you can achieve a better system balance, simpler station design and a smaller footprint.

Register for the conference at Automate Registration.

Sponsored Recommendations

Latest from Electromechanical

Leaders relevant to this article: