Fredrik Ryden is CEO of Olis Robotics.

As industrial robot installations continue to rise, they continue to be integrated into work cells for palletizing, machine tending, welding and other industrial applications. What innovative or efficient robot-integration applications have you seen or been involved with?

Fredrik Ryden, CEO, Olis Robotics: We have deployed our remote monitoring and controls software on everything from palletizing cells to highly customized cells used for handling radioactive samples. The common thread across these deployments is that a continuously monitored cell is faster to deploy and easier to operate and maintain.

What have been the biggest improvements to robot integration and interoperability with other robots or components in work cells in the past five years?

Fredrik Ryden, CEO, Olis Robotics: There is a growing awareness that communication on the plant floor doesn’t need to be real-time, except at the lowest levels of the technology stack. This greatly simplifies software and hardware interfaces since standard PC hardware can be used in combination with well-supported open protocols, such as representational state transfer (ReST) application programming interfaces (APIs).

The ability to operate using standard hardware and software means access to a complete ecosystem of software tools and people. In turn, this increases the chance of a successful initial deployment and enhances the likelihood of a quick resolution should any problems arise.

Can you explain how software or open-source control architectures have changed robotic integration?

Fredrik Ryden, CEO, Olis Robotics: Although not immediately obvious, open-source software is built into many of the devices that operate on a production floor. Note that much of this software was not explicitly developed for the manufacturing realm, such as Linux, but other software, such as Robot Operating System (ROS), were developed with automation in mind.

Open-source software plays three important roles. First, it is neutral, which makes it easier for competing vendors to rally behind it. Second, it is auditable, so anyone can see how it was written, which can increase trust. And, third, it is easily accessible and often free of charge, which supercharges innovation.

All of this results in software and hardware that is easier to integrate on the production floor.

As manufacturers and warehouses/distribution centers push toward autonomous operations, what is the benefit of collaborative robots (cobots) and their ability to work alongside humans?

Fredrik Ryden, CEO, Olis Robotics: Cobots are the most impactful technology in industrial automation over the past decade, but there is still some way to go to make industrial automation easier to use anywhere and by anyone.

It’s important to understand the strengths and weaknesses of collaborative automation. Cobots have been amazing at lowering the barrier to adoption of industrial automation, making industry-grade automation available to companies of all sizes, even those with no prior robotics experience.

One of the key benefits of cobots is the ability to physically grab and move the robot around as part of the programming process. This hand-guiding method or programming is extremely intuitive and ideal for many applications. In welding applications for example, a welder that has never used a robot before, but knows where the end-effector should be positioned to complete the task, can easily hand-guide a cobot through a welding process, instead of spending hours programming via traditional programming pendants.

However, cobots have their limits. There are some applications that require higher-speed or higher-payload capabilities. Traditional industrial automation is well-suited to these applications, especially in low-mix/high-volume production environments.

When will robotics technology become user-friendly enough that integration, installation and operation is plug-and-play and no longer requires extensive engineering?

Fredrik Ryden, CEO, Olis Robotics: To truly unlock scale in industrial automation, it needs to be simpler to integrate, install and operate. For many common applications, we are already very close to this vision when it comes to integration and installation. Such applications include packaging and palletizing, machine tending, welding and pick and place.

However, when it comes to operation, end users are still burdened with extensive training requirements to ensure that they are proficient enough to keep their equipment running optimally.

To achieve a true plug-and-play experience we need to provide end users with software tools that can help to monitor and keep equipment running and provide immediate assistance when problems arise. In the long-term, artificial intelligence (AI) might be of assistance. In the short-term, however, these capabilities most likely come from remote monitoring and debugging software.

What future innovations will impact the integration of robotics technology in work cells and with other industrial machinery?

Fredrik Ryden, CEO, Olis Robotics: Innovations that can boost value already exist, including remote monitoring and control technologies, AI vision and cobots. However, a more holistic approach overall is needed to achieve true scale in industrial automation.

The entire automation industry, from automation original equipment manufacturers (OEMs) to system integrators need to work together to deliver products and, more importantly, the services required to ensure that end users are successful with automation every time they deploy it.

In this way, by eliminating risk and creating a predictable buying experience, automation investments become no-brainers.

Tell us about your company’s state-of-the-art robotic integration into a work cell or transporting materials/goods between cells.

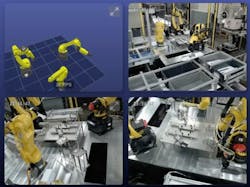

Fredrik Ryden, CEO, Olis Robotics: Olis enables automation and robot cells to be remotely monitored, diagnosed and controlled. This applies to all of the common applications including picking, packaging, palletizing, welding, material removal, machine tending and assembly.

Integrating a complete assembly cell with a combination of discrete automation and robots can be quite a daunting task. In the early days of deployment, myriad unexpected problems can show up, and in such cases it’s important to get the facts as fast as possible.

Olis’ video alert feature functions like an airplane’s black box. When an unexpected fault or error occurs, the last 30 seconds of video is stored and optionally emailed out along with the relevant log files. Having all the relevant information in a single place makes it straightforward to diagnose issues and quickly resolve them.