Looking back in hindsight on 2020, where does integrated control and safety stand? And where might it be headed in 2021 and beyond?

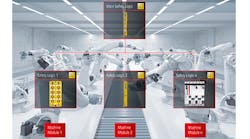

Aga Zupancic, product marketing manager for modular PLC, and Rob Ruber, senior product marketing manager for controls and visualization, Mitsubishi Electric Automation: We have certainly seen an increase in the demand for integrated safety in our customer base this year. While there will always be a place for the traditional e-stop and safety relays, technology has changed to the point where it’s possible to connect all your control and safety devices on the same network and program them in a single software (Figure 1). This integration allows for the ability to not only see when a fault occurs, but handle various situations in the best way to:

- ensure a safe response in the area(s) of concern

- adjust the process in a calculated way to continue running stages in the line not impacted by the situation.

Figure 1: While there will always be a place for the traditional e-stop and safety relays, technology has changed to the point where it’s possible to connect all your control and safety devices on the same network and program them in a single software.

(Source: Mitsubishi Electric Automation)

The process response can range from running at a slower speed to create backlog, to stopping entirely until the area(s) of concern are addressed.

This flexibility, in combination with the ability to obtain information that assists the machine user in identification, troubleshooting and corrective actions is a selling point that we see machine builders using more to set themselves apart from their competition. We are also seeing machine builders take advantage of additional benefits including a reduction in wiring and panel size, as well as reduced programming and commissioning time, thanks to a single programming environment.

Daniel Weiss, senior product manager, Newark: Industrial automation processes, as well as the machines, are becoming increasingly dynamic. The need to increase productivity, flexibility, ergonomics and safety has become indispensable. 2020 saw continued efforts in expanding products providing solutions for the integrated-safety-and-control market. The key to integrated-safety-and-control solutions is integrating it into the design of the machine or its control components from the very beginning.

Managing an industrial project today is a challenge. Despite taking into account all technical aspects and rules, saving time and money is a must. To achieve that, all systems should be flexible in all aspects: reusing program codes, wiring and modularity. In addition to the safety aspect, one can benefit from all diagnostic information available from any location. Whether in front of the machine or at a desk, the same level of information is available. When using integrated safety, the cost of the components is slightly higher, but it reduces exponentially the time spent during the planning, installation and programming, as well as during the setup and startup.

During 2020 many safety-specific products were introduced including safety PLCs, safety I/O modules, safety drivers, motion control and motor-control products—all designed to enhance safety on and around machines and to work together with sensors, safety relays and safety switches. These safety systems all tie into the Industrial Internet of Things (IIoT) network, allowing the flexibility of available data from anywhere.

Todd Mason-Darnell, Ph.D., marketing manager—services and safety, Omron Automation Americas: Integrated safety moved into the mainstream for OEMs and end users in 2020. In addition to the cost savings of installing a safety network as opposed to a safety-by-wire solution, integrated safety gave OEMs an holistic approach that simplified machine design, shortened commissioning time and enabled them to get to market more quickly. End users found that they could minimize costs for maintenance, setup and training with a single integrated development environment for safety and a safety network. More importantly, and particularly for end users in 2020, integrated safety solutions provide value by enabling greater flexibility in (re)configuring production lines. In 2020, flexibility is king.

Looking ahead, we can see that integrated safety solutions will be an enabling component for three related trends that help to empower production and maintenance teams to make functional safety more adaptable to the changing demands. These three trends are as follows:

- Intelligent safety. In this trend, functional safety becomes part of IoT/digitalization and visualization initiatives. The safety network will feed data not only for traditional big data uses (predictive maintenance, OEE), but also for support visualization applications with the gool of minimizing the need to expose people to dangerous equipment during production or maintenance activities.

- Interactive safety. This refers to the development of a common safety platform that will allow maintenance teams to monitor and diagnose events from different vendors over a single network.

- Collaborative safety systems for fenceless solutions. Integrated safety will become a key component for adaptive collaborative applications that leverage safety sensor data, machine reaction times and safe motion functions to ensure the operator's well-being without the use of traditional hard guarding or fixed hazard zones.

Sree Swarna Gutta, I/O product manager, Beckhoff Automation: Looking back, 2020 has been very tough for many companies, but it has also given engineering teams time to explore new technologies. Many began to evaluate integrated, programmable safety because they had the time to invest and understand whether it could enhance their machines. We have seen machine builders and manufacturers implement integrated safety to a greater extent than ever before. This area of automation technology has a come long way from standalone safety controllers with separate software and excessive hardwiring. As a result, engineers increasingly recognize the payoff to the integrated approach.

Figure 2: TwinSAFE modules in standard I/O segments provide protection at necessary SIL levels via the EtherCAT industrial Ethernet system.

(Source: Beckhoff Automation)

Beckhoff customers are getting more conformable with TwinSAFE integrated safety options because of its ease of use, cost savings, enhanced diagnostics and simple programming in the universal TwinCAT environment, among other benefits (Figure 2). TwinSAFE has evolved with analog safety and safety logic directly in drives, and many companies have a long track record of using these technologies to build safer machines. In the coming years, I only see integrated safety growing—both in the number of solutions available and in widespread adoption across industries. Hindsight is 20/20, and when looking back at standalone systems, it’s clear that integrated safety is the future in machine design (Figure 3).

Figure 3: Integrated safety systems, such as TwinSAFE, incorporate safety program engineering into the universal TwinCAT 3 automation platform used for PLC, motion control and more.

(Source: Beckhoff Automation)

Ted Cowie, vice president sales safety and industrial products, Motion Industries: Integrated safety is even more important than it was as we entered 2020. With all of the new challenges associated with COVID-19 and the necessary protocols for distancing and safe workspaces, companies are accelerating their efforts at automating more production processes. This means there must be an even greater focus on worker safety for those who will have the responsibilities to interface with these systems and the equipment they control.

As we move forward, there will be more awareness and emphasis on this component of automation, so new or enhanced solutions will have been designed with safe operation and maintenance as a foundation. As with any safety systems/process project, a thorough risk assessment must lead the way. With new automation solutions, this assessment must look outside the familiar safety process boxes to make sure the designs will always deliver a safe operational environment.

John D’Silva, safety technology manager, Siemens Industry: Covid-19 has greatly focused companies’ attention on integrated safety. While people everywhere are becoming concerned and serious about personal safety during the pandemic, those in the industrial workforce are also taking proactive steps toward workplace safety and machine safety. In the past six months, we have received numerous inquiries each week from industrial customers requesting risk assessments, safety validation and integrated safety designs for their automation systems.

Looking back at NFPA 79, 2002—which first allowed the use of safety PLCs and safety networks—integrated safety has increased by leaps and bounds at Siemens Factory Automation. New, innovative and advanced safety technologies are now available, especially in robotics with developments in safe kinematics, mobile safety HMI panels and integrated safety (Figure 4). We’re seeing these capabilities in AI and edge solutions, accelerating users toward digitalization and greatly increased productivity.

Figure 4: New, innovative and advanced safety technologies are now available, especially in robotics with developments in safe kinematics, mobile safety HMI panels and integrated safety.

(Source: Siemens)

Kyle Hall, senior product engineer, Turck Fieldbus Technology: As safety continues to grow as a topic in both the machine design and machine integration spaces, functional-safety vendors continue to innovate to bring products and solutions to market that simplify and closely integrate safety functions with the standard control system. With many industrial PLCs supporting functional safety fieldbus protocols, machine builders and integrators have a wide variety of products and protocols to choose from. As functional safety products progress at the machine level, you will see tighter integration of safety and standard I/O in single modules such as blocks, drives and valve banks. You will also see higher flexibility of output devices with regard to tolerating safety pulsed power and the ability to span or translate safety-relevant data from one system or protocol to another. Couple that with active safety steering groups and emerging standards for industrial protocols like IO-Link and OPC-UA and machine builders and integrators will have tools to easily bring their safety-relevant data from machine to machine as well as from the sensor to the cloud.

Russ Freeman, product portfolio manager, Allied Electronics and Automation: The technology and innovations in automation have outpaced the evolution of safety technology. Some of that is there is more tolerance for risk in automation innovation than in safety innovation, as it should be, so we can have a tendency to default to what’s worked and been proven in the past when it comes to safety equipment. I think we are starting to see some shift in that trend as we look forward, and the COVID-19 pandemic has also been a very acute reminder of the importance of workplace and facility safety. As a distributor, Allied works with several manufacturers of safety equipment. I’ve seen some of our manufacturers leading with innovations in machine safety such as Schmersal, Pilz, Banner Engineering and Omron. New products such as Schmersal’s Bluetooth interfaces for real-time diagnostics on safety components that connect to a computer or mobile device and plug-and-play field boxes. Pilz Safety Device Diagnostics (SDD) enable you to call up extensive diagnostic data resulting in greater machine availability and reduced downtimes. Banner Engineering has created In-Series Diagnostics (ISD) that makes it easy to access diagnostic data from safety devices without special equipment or designated cabling. Omron offers Functional Safety over EtherCAT (FSoE) and CIP Safety over EthernetI/P for improved communications and connectivity. Connectivity, especially real-time connectivity, is already a huge part of factory automation, and we will see a similar heavy level of improved connectivity and communications in integrated safety capability as we move into the future.

Matt Wren, senior project manager, safety product division office, Keyence: 2020 so far has revolved around trying to understand an ever-changing reality in the factory automation industry. We have relied heavily on our local safety specialists and their direct contact with our safety users. The two most consistent themes we’ve seen so far in 2020 are safety users turning to what’s familiar and what’s available. The biggest driver being product availability.

Looking ahead, we anticipate familiarity and availability still being important; however, we are also seeing safety users looking at consolidation and efficiency. This includes reducing space inside cabinets by replacing multiple safety relays with a single safety controller or PLC. Not only do these devices save space, they also provide streamlined monitoring and troubleshooting capabilities to quickly identify issues and minimize downtime. Additionally, we are seeing increased interest in distributed I/O throughout the machine to simplify wiring and expedite integration.

Sergio Diaz, safety instrumented systems manager, Emerson: Integrated safety system adoption continues to expand within process operations because end users better understand the proven benefits in simplifying project execution, operations and cybersecurity. It has become clear that integrated safety systems that maintain a functional separation are as defendable or more defendable than traditional interfaced systems.

On an interfaced system, the whole SIS, both safety-critical and non-safety-critical components, are isolated from the BPCS. While an interfaced system might be perceived as good strategy, the reality is that multiple connections are required to interface and these connections require cybersecurity protections. With an ICSS, the safety-critical components are isolated and the DCS integration is done at the level of non-safety-critical components.

The strength of the ICSS is that the control system provides additional layers of defense for the SIS. The integrated system can share a set of defense-in-depth layers for many common defense systems: antivirus, whitelisting, firewalls, and more — to simplify management for the asset owner. These defenses for both systems are easier to maintain because the interface does not rely on custom engineering. The SIS uses its own defense measures that provide extra protection to safety-critical features.

The end result with an integrated safety system is you get additional cybersecurity protections and the benefits of easier, less expensive project execution, which are top of mind concerns for all manufacturers.

Bill Davis, solution director of industrial machinery and heavy equipment industry, Siemens Digital Industries Software: 2020 has proven, beyond a shadow of a doubt, why manufacturers across the globe need to invest in autonomous machinery to support critical infrastructure and process elements of their plants. From worker shortages to global supply chain breakdowns, COVID-19 has demonstrated how connected the world has become and how fragile most of our manufacturing and supply infrastructure has become.

Huge progress has been made to realize intelligent, connected machinery, as described well by the characteristics of Industry 4.0. Over the past few years, the term “cobot” has emerged in our lexicon, as well, and now machines operate both autonomously and in collaboration with their human counterparts. This puts a huge burden on machine builders and system integrators to embed highly redundant, safety systems as part of their hardware and software code delivery.

Safety must be intuitive and predictive. Automobile safety with regard to automated braking and lane departure has become just that. The vehicle can “look through” the vehicle in front of you to traffic up ahead to keep you out of harms way, and by the same token, anticipates you may wander out of your lane well before your tires hit the painted lines.

Machinery and robotics systems designers must take on the added burden to bring that same philosophy to bear. Machines that start and stop autonomously are not predictable to outside observers, and so too are robots that can exert tons of force in a few milliseconds. The good news is that the same sensor technology employed on passenger vehicles has become far more cost-effective and can be readily adopted.

One concern we hear repeatedly from machine builders is how complex PLC code has become, how rapid that change has come and what a challenge it is to debug and validate, especially related to safety-related issues. IoT sensors have become both modularized (codeful) and ubiquitous, and so every sensor reading could have a potential safety impact. Does the machine shut down due to a high bearing temperature reading, or does it slow down to allow the bearing to cool? What if the rate of temperature change borders on the catastrophic and the bearing could seize in a few cycles?

Automation code designers have an awesome responsibility to build both deliberate, or intentional, code and adaptive, responsive code that cares for both the safety of operators, as well as the health of the machine. Making sure those two don’t conflict and work properly can only be done through simulation of the machine and code in such a way that both machine operation and safety can be validated with a digital twin.

Historically, machinery development has been done in silos with sequential tasks arrange by discipline—mechanical designers use CAD to design the physical machine, electrical engineers take the functional design and the devices specified by the mechanical designers and ensure they can be powered and controlled properly, and software/controls engineers take the logical systems and build safety and operational code from the electrical system.

What is needed is a set of tools that can handle the critical system elements throughout and communicate across disciplines. The digital model of the mechanical system can be simulated physically in a logical order and time sequence, and both the sequence and assignment of logical devices are available to both electrical and automation engineers. In this way, all three disciplines can collaborate on the design and adjust accordingly through the development cycle.

What is even more needed is a way to bring the code back into a model of both the HMI and other interface types and the digital twin of the physical model (Figure 5). The actual code is used in this simulation and both input and response are demonstrated accordingly. For example, if the HMI is used to start the machine, the start sequence can be initiated by touching the necessary panels on the screen with cursor, and the digital twin goes through its operating sequence. In the same way, safety circuits can be tested. By opening the door of the model, the machine will respond both physically (e-stop) and the HMI display will reflect the fault condition.

Figure 5: What is even more needed is a way to bring the code back into a model of both the HMI and other interface types and the digital twin of the physical model.

(Source: Siemens)

But this is not only a theoretical exercise in what is possible. Tronrud Engineering, a manufacturer of secondary packaging machinery in Norway, provides some key insights into the practical application of virtual code validation. Through investment in automation code simulation and verification from Siemens Digital Industries Software, Tronrud has been able to bring the world’s fastest packaging machines to market in half its current development timelines, highlighting a 50% in commissioning time.

In today’s multi-faceted manufacturing environment, the health and safety of employees needs to be of paramount concern, and with thus its essential-to-have functional simulation capabilities for material flow, machine operation and ergonomics and social distancing of physical human traffic patterns and work.

By modeling material movements within the plant, using 3D representations of the environment, you can optimize the flow of physical assets such as lift trucks, as well as humans in their work cells. Congested traffic areas for equipment are often congestion points for pedestrians as well, which can be simulation in the same modeling environment. Additional points of ingress and egress can be modeled and tested to ensure social distancing.

We must not focus so much on social contact that we forget the need to design the work to minimize workplace injury due to bad ergonomics or repetitive stress. Being able to demonstrate with human models and recreate the work functions, the proper techniques and processes can be identified and built into digital operator training material.

In summary, 2020 has provided an opportunity to re-examine the integrated safety with the entire plant, from the machines we build and commission to the plant environment itself. We must re-examine how we design safety systems to be more intuitive and flexible in a more complicated worker-machine environment. We further need to challenge ourselves to invest in the manufacturing floor, and not look simply at providing proper distancing to keep employees safe, but look holistically at the plant to unlock ways to improve our employees’ health and create efficiencies we often overlook in our hectic struggle to meet deadlines and maintain production quality.