Open protocols and data analysis are the future of ICS

The acceptance and advancement of more open protocols will help further enable the adoption of integrated control and safety (ICS) systems. Machine-to-machine communication is necessary for the joining of safety and control, but together, they can enhance overall system communication, data collection and analysis, and predictive maintenance.

As the industry moves toward more open protocols, this will also open new avenues for integrated control and safety. “Open communications are an absolute must,” says Christopher Woller, safety product manager at Beckhoff Automation.

Also read: More open protocols and processing power advance integrated control and safety

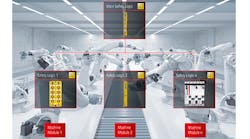

Consider a modular filling line. “Perhaps the OEM sells a filler, a sealer and a labeler as separate machines, and customers may purchase one, two or all three cells together,” Woller says. Open machine-to-machine communication is needed to work a simple emergency stop across all three machines (Figure 1).

“This is why TÜV-certified and IEC 61784-3-standardized protocols are so important. Without this open communication, it is left to the end user of the filler, sealer and labeler to perform an additional risk assessment and reduce risk accordingly. This can lead to an undesirably complex safety function that is hard to maintain,” Woller says.

Fully integrated safety also simplifies diagnostics with loads of data. “Having the safety data available in that standard environment would be a major advantage to provide visibility into overall machine performance beyond information on throughput, quality and condition monitoring,” Woller says.

Michael Bowne, executive director at PI North America also supports the advancement of open protocols. PI North America supports Profibus and Profinet fieldbuses. “In the case of a Profinet network, the safety messages are transported via Profisafe. They are merely Profinet messages but with some extra data to guarantee safety messages get from a sender to a receiver,” Bowne says.

“Until recently, machine-to-machine functional safety communication has been the missing link in any modern safety network,” Bowne adds. Without vendor-agnostic standards, solutions were highly customized and/or proprietary. Bowne said that changed when the OPC UA Safety Core Specialization was released in March 2020.

OPC UA Safety was initiated as a joint working group between the OPC Foundation and Profibus and Profinet International (PI), an international umbrella organization, but has now been merged as a technical working group under the auspices of the Field Level Communication (FLC) initiative (Figure 2). OPC UA is based on the black-channel principle and currently addresses controller-to-controller communication using OPC UA clients and servers.

Bowne says OPC UA Safety takes machine-to-machine (M2M) safety even further with features such as dynamic addressing. “Traditionally, safety nodes’ addresses are static, as this helps support data authenticity. But in a world where autonomous mobile robots (AMRs) are becoming more prevalent, dynamic addressing is required. An example would be safety-related communication between a stationary machine and an AMR that has arrived just-in-time to complete a task before moving along,” Bowne says.

K.C. Mangen, product manager of safety sensing at Omron says the biggest driver of ICS-system adoption is the increased desire to collect more data and use analytics to improve processes and predictive maintenance on equipment. Omron was already seeing increased interest in safety networks, and, in some ways, the pandemic has increased the desire for more connected systems. A single integrated software environment helps fewer workers manage a larger network, Mangen says. “From the safety networking side, I think there was also a real pressure to be able to view things remotely,” he adds.

Also, in some ways, the slowdown from COVID-19 gave companies downtime they didn’t have before and the time to consider new tools and training, he adds. “It kind of hit a little bit of a reset button,” Mangen says.

“COVID really showed the need for customers to be flexible,” says Michael Warren, product manager of safety components and safety controllers at Omron. This is true in terms of the types of safety equipment and networks companies use and also how those machines communicate. “The trend is to get away from proprietary networks to open protocols,” Warren says. More often, Omron sees customers with a mix of equipment and brands. “Customers are diversifying their needs, so they don't lock in with just one vendor in case of supply and demand challenges,” Warren says. This equipment mix depends on even more open protocols and M2M communication.

The future likely holds more for integrated control and safety. “I think the biggest innovations coming are going to be more capability on the internal side— being able to run your safety, being able to visualize your safety system more efficiently,” says Mark Russell, tech application support manager at Allied Electronics & Automation. Even with integrated systems, he says, often highly competent safety engineers are needed to work with safety systems.

“I think the integrated systems are going to bring that back to a more industrial base, and that's going to be very helpful,” Russell says. “I think that’s probably the future, making safety a little more seamless and a little easier to integrate, and hopefully a little more foolproof, so that we don't have holes in our safety system.”

About the author: Anna Townshend

Anna Townshend has been a writer and journalist for almost 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, published by The Waterways Journal, until she joined Putman Media in June 2020. She is the managing editor of Control Design and Plant Services. Email her at a[email protected].