Lee Van Every, senior account manager at Cenit North America, will be giving a presentation on advanced manufacturing and future production environments, as part of the How Manufacturing is Impacted by IIoT / Industry 4.0 session on April 4 from 3 pm to 5 pm at Automate 2017 in Chicago. Contact him at [email protected].

Industry 4.0 is so named because it’s the fourth incarnation of the Industrial Revolution. It represents the radical change that’s shaking the very foundations of the manufacturing floor. Digital factory software and 3D tools are driving that change forward.Industry 4.0 is a new paradigm for the structure, planning and execution of production equipment and processes using modern IT and communication methods. It requires all-new ideas and concepts, and new software tools for the digital factory are blazing the trail.

First, 3D-based simulation software lets us visualize and validate processes and production tasks. Manufacturing plants are often re-planned while production is running. Software to do rudimentary modeling isn’t new. But to transform IIoT/Industry 4.0 concepts into reality, these model factories must become virtual twins of their production counterparts.

This goes beyond the geometric and kinematic to mimic detailed logic, behavior and control of the actual manufacturing units. This is the only way to move from stiff, prescribed processes to agile, self-organized production units.

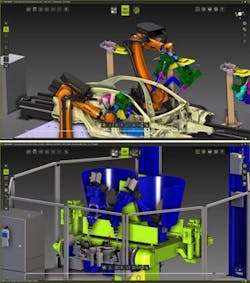

Figure 1: A virtual-twin model allows for the implementation of manufacturing processes, techniques and technologies that would be too expensive, or even impossible, without such simulation-based solutions. From simple to highly complex tasks, such as collaborative robotic applications, the greater the need for advanced programming and simulation.

Secondly, a virtual-twin model allows us to implement manufacturing processes, techniques and technologies that are far too expensive—or even impossible—without such simulation-based solutions. From simple to highly complex tasks, the more robotic applications we use, the greater the need for advanced programming and simulation (Figure 1).With these new programming and simulation environments, operators can create working applications with confidence, where before they could hope only the model represented a quality result.

Cyberphysical systems

A virtual copy of the production line does not itself add value to intelligent manufacturing. Smart production can only happen when the virtual components communicate exactly as actual components will in the real environment.

This internetworking of components—the Industrial Internet of Things—is the core of Industry 4.0 and opens the way to cyberphysical systems. Instead of rigid automation lines and static robotic systems, IIoT enables flexible, cooperating and agile automation solutions. Instead of static, inflexible models, we can conceive and create production systems that handle unlimited product variants. And, because we can quickly alter any production plan, we can produce batches of any size efficiently and less expensively.

That’s good news for even the smallest company. The methods of Industry 4.0 and smart manufacturing allow for smaller quantities and lower production volumes. Companies of all sizes can realize the benefits of implementing smart manufacturing.

Give the manufacturers what they want

What do companies need to break into smart manufacturing? First, the software must allow for harmonious integration with existing systems, data structures and customer processes.

It must:

- be compatible with existing CAD systems

- work with any manufacturer’s robots and machines

- support relevant technologies, applications and system designs

- be extensible to include new technologies

- be cost-efficient and user-friendly.

In short, the software tools must be usable, affordable and based on an open and scalable software structure.

Finally, the tools must produce rapid, concrete results, from the smallest project all the way to large, full-scale process automation projects. Digital factory software must be modular, extensible and scalable, so it can grow and adapt with the company’s changing needs.

[javascriptSnippet ]

Marrying simulated and real behaviors

System integrators must provide accessibility tests and feasibility studies, often before winning a job. Using a digital catalog of mechatronic resources, they can produce and validate high-quality 3D layouts and simulations. But does the resulting simulation reflect the behavior of the actual manufacturing cells to be built?

The integrator could create a quick layout with 3D CAD components from the catalog and then program the scripts and macros to simulate the material flow and behavior of the cell. But why be limited to standard components?

It would be simpler to use mechatronic components, while simultaneously defining a schematic logic for the production island. Because the simulation uses the same PLC programming logic you’ll use later in the real system, its behavior is also an accurate representation. If the software provider has done its job, this process should be quick and easy, without the integrator needing programming skills.

The digital factory software should support virtual commissioning, allowing you to replace control emulators with real components during the acceptance phase. The integrator should be able to write simulation data into shared memory, so the 3D visualization can read it and so emulators and real controls can be interchanged.

Being able to swap real components for emulators lets the integrator test the virtual model against real controls before putting the system into operation. Virtual commissioning reduces risks, errors and downtime in production.

Once the production islands are live, operators can use the same virtual layout to introduce new parts and products, thus eliminating time-consuming teach-ins and the resulting production interruptions.

ALSO READ: How do I make precision-motion machinery IIoT-ready?

New industrial revolution

The trend toward and demand for greater flexibility in manufacturing by using machine- and robot-based applications is unstoppable. The eventual result will be adaptable processes that can efficiently produce a batch of any size, whether it’s one or 1 million.

Industry 4.0 provides the concepts necessary to realize these goals. The actual transformation, however, will force system integrators and software companies to create mechatronic systems that demonstrate a one-to-one relationship to real production conditions, which is why digital factory solutions are the key to making Industry 4.0 a reality.

About the Author

Lee Van

Cenit North America

Leaders relevant to this article: