Our current pulse-taking of advances in industrial motors and drives finds suppliers pointing out several interesting trends.

Jimmy Koh, marketing manager, Rockwell Automation, says the design of compact ac drives has mirrored that of consumer electronics in packing more performance-enhancing features into smaller, user-focused designs. "In fact, machine builders that restrict their selection criteria to simply sizing a drive can miss out on features that can help them be more competitive," he says. "Although drive-control technologies, such as volts per hertz control and sensorless vector control, have remained relatively unchanged over the last decade, drives engineers have bettered them with features that ease communications, improve safety, speed installation, and minimize programming, configuration and commissioning time. The result is lower costs to design, develop and deliver machines."

Also Read: Industrial Motor Efficiency and More

Smaller footprints and simpler systems are also important. "As machinery and devices become more compact and space-constrained, the latest trends in motion control point toward the two primary goals of making controls components and systems simpler and smaller," explains Matt Lecheler, motion specialist, Beckhoff Automation. "Miniaturizing drive components is now more of a necessity than a luxury because of end users' need to use plant floor space efficiently."

An example comes from one of the company's servo terminals that has one-cable technology (OCT), and halves the number of drive cables and connections typically required.

MTPM series IronHorse electric motors in fractional sizes ranging 1/31 to 1/4 hp, feature rolled steel, totally enclosed, non-vented (TENV) housings, high-energy ceramic magnets and replaceable brushes. The motors mount in any orientation, and accommodate 12, 24, 90 and 180 Vdc. They are UL-, CSA- and RoHS- compliant, IP40-rated, and come with 18-in. leads or fitted with junction boxes with 8-in. leads.

AutomationDirect;

800/633-0405;

ACS250 micro drives include standard IP20 panel-mounted chassis and a IP66/UL Type 4x enclosure, which targets environments such as washdown applications that require on-machine mounting. IP20s are available in one-phase 115 V In and three-phase 230 V Out, and 600 V In/Out. IP66s range from one-phase 115 V In and three-phase 230 V Out to 600 V In/Out. All units feature enhanced V/Hz control with variable-torque or constant-torque V/Hz profiles, and an embedded Modbus-RTU communication interface for real-time control and monitoring.

ABB;

800/435-7365

Acoposmotor combines a servomotor and drive in one compact unit that connects to a Powerlink network using a hybrid cable. Modules come in three sizes with torques 1.8 to 12 Nm, and include wired safe torque off (STO) and SS1 safe operational stop 1 (SS1) safety functions.

B&R Industrial Automation;

770/772-0400;

Super-E motors are available in 1 to 50 hp in totally enclosed fan-cooled (TEFC) or open drip-proof (ODP), foot-mounted designs, and with 1/2 to 5 hp in TEFC, C-face, foot-mounted designs. The motors have a carbon brush mounted internally to divert shaft currents away from motor bearings and prevent voltage spikes from damaging the bearings.

Baldor Electric;

479/646-4711

EL7211 EtherCAT servo terminal provides drive power for the company's AM31xx and AM81xx series of servo motors up to 4.5 rms at 50 Vdc. The terminal is available with integrated resolver interface or the company's one-cable technology (OCT). The terminal features a compact, 24-mm wide housing.

Beckhoff Automation;

877/894-6228

AKD-N distributed, servo-drive system combines IP67-rated drives positioned next to the motor and supplied by a central power module in the switchgear cabinet. An 11-mm diameter hybrid cable delivers power and fieldbus communication to the drives, which thereby operate directly in series, supplying up to 4 kW per axis. The drives feature safe torque-off technology.

Kollmorgen;

540/633-3545

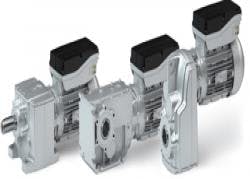

Helical, helical-bevel and shaft-mounted helical g500 gearboxes change motor speed into torque, which, according to the company, supports efficiency of over 94% across the entire transmission range. The gearboxes are available in sizes 45-600 Nm and have aluminium housings. They work with the company's Smart Motor, IE2 MH three-phase ac motors, inverter-optimized MF motors, and MCA and MCS servomotors.

Lenze Americas;

508/278-9100

Roller Pinion System (RPS) provides linear positioning with zero backlash. RPS features a roller pinion/toothed rack combination where the pinion comprises bearing-supported rollers that engage a unique tooth profile. Racks are available in 1-m and ½- m cut lengths as well as custom lengths.

Nexen Group;

651/484-5900

PremiumPlus+ electronically commutated permanent magnet motors use low-cost, ferrite magnets in a flux-focusing design to deliver the efficiency of rare-earth permanent magnet motors at a cost said to be competitive with induction motors. Driven by VFDs, the units have a motor-only rated point efficiency of over 94%. Packaged in standard NEMA frame sizes and mounting dimensions, they are compatible with VFDs from most leading manufacturers, and come in 7.5-hp and 10-hp

models.

NovaTorque;

510-933-2700;

Accurax G5 servo drives and motors with built-in EtherCAT include servos up to 15 kW. Mounting the drives side-by-side reduces cabinet space needs. They feature a 2-kHz response frequency and have built-in safety torque off (STO) technology conforming to ISO13849-1 Performance Level D (PL d).

Omron Automation and Safety;

847/843-7900

Weighing 1.9 oz, 22NT Athlonix Brush dc miniature motors provide maximum continuous torque up to 16.6 mNm, are compatible with incremental encoders and gearheads of various sizes and ratios, and have high power density from an energy-efficient, coreless design with an optimized self-supporting coil, magnetic circuit and graphite commutation system.

Portescap;

610/235-5499

EC-i brushless dc motors use high-powered, permanent magnets, and provide low inertia and minimal detent. They feature robust bearings and compact construction, and are available in 40-mm diameter, 26-mm (50 W) and 36-mm (70 W) lengths.

Maxon;

508/677 0520

Zero-Max Crown right-angle gear drives are lubricated for life and have heat-treated AGMA Class 10 spiral bevel gears. They have precision-hardened and ground ball bearings for speeds up to 2,000 rpm. Internal gears are permanently mounted to the shafts with locking pins. Operating range is -50 to 120 °C. Standard two- and three-way models have 1:1 and 2:1 speed ratios in shaft diameter combinations of 3/8, 1/2, 5/8 and 3/4 in.

Zero-Max;

800/533-1731

PowerFlex 523 AC drive lets users employ a standard USB connection for uploading and downloading drive-configuration files. Users can also program the drive with its built-in HMI module. The drive lets users leverage an optional dual-port EtherNet/IP adapter for a module that supports ring topologies and provides device-level ring functions. The unit has a power range of 0.25-15 hp and motor-control options, including volts per hertz, sensorless vector control and Economizer mode in sensorless vector control.

Rockwell Automation;

414/328-2000

SEZ is an installation-ready, electric cylinder that consists of a servomotor with an integrated linear unit. The motor rotor is pressed directly onto the ball screw, eliminating the need to use coupling elements for the connection. The linear drive train provides a force range up to 8.3 kN axial force, stroke range up to 70 mm, and high positioning accuracy.

AMK;

804-222-0323

Sigma-5 ServoPack drives provide STO, SSI, SS2 and SLS safety functions and comply with safety category 3 standards. They include a safe torque-off (STO) function as well as optional safe stop 1 (SS1) safe stop 2 (SS2) and safe limited speed (SLS) functions.

Yaskawa;

847/887-7318;

Vacon 100 X drive has a UL Type, 4X (IP 66), die-cast metal enclosure rated for 0 to 100% relative humidity, 3-g vibration resistance and 25-g shock for 6 ms. Operating range is 10-40 °C. The unit works with both induction and permanent magnet motors up to 50 hp and includes an integrated STO mode. The drive comes with standard RS485 and industrial Ethernet communication. Input line voltage is 208-240 or 380-480 Vac.

Vacon;

877/822-6606;

GVM210 traction motors for electric and hybrid electric vehicle traction applications include a 210-mm frame size, within which there are six rotor lengths and numerous winding variations. This gives the motor more than 100 combinations of base speed and peak power output. The motors provide peak power of 8-325 kW and peak torque of 76-703 Nm. They have operating voltages 24- 800 Vdc and a base speed range of 843-7,575 rpm.

Parker Hannifin;

707/584-2417

For upgrading the performance of systems using less sophisticated motion control without redesigning everything, the PDICL drive interface delivers closed-loop motion control for stepper or servomotor drives with an incremental or absolute digital encoder feedback device. The compact module targets multi-axis machinery OEMs that use an ACS EtherCAT master, and need to control additional axes using third-party drives.

ACS Motion Control;

800/545-2980

CMMP-AS-M3 servo drive has optional slide-in network cards for all supported networks, and an optional slide card with STO functionality. Drive configuration and diagnostics are handled via integrated Ethernet interface (TCP/IP) for both direct- and remote-drive access (single or multiple drive systems). An SD memory card for storing and loading parameter settings can be used to duplicate settings for high volume production of machines and restoring drive configurations.

Festo;

800/993-3786

Single-axis Sinamics V20 drive comes in four frame sizes across 1/6–20 hp, and can be connected directly in-line and mounted as a push-through installation in addition to the conventional wall-mounting method. Integrated basic operator panel (BOP) enables on-site commissioning and operation. Universal serial interfaces connect to Simatic PLC controllers, and a Modbus interface is included. Pre-built connection and application macros are used for application-specific settings.

Siemens Industry;

800/879-8079;

Lexium MDrive integrated motor products are available with EtherNet/IP, ModbusTCP, and CANopen protocols. Models with an internal encoder include hMTechnology to close the feedback loop for stepper systems and servo motor applications. They're available in NEMA 23 and 34 motor sizes, with operating power range of 12-70 Vdc.

Schneider Electric Motion USA;

860/295-6102

WSS stainless-steel ac motors have windings doubled-dipped and cured in polyester insulating varnish, anti-rust coated rotor, and double-lip seals plus V-ring shaft slingers. The three-phase industrial-grade washdown duty motors come in sizes 1/3-2 hp.

Omega Engineering;

203/359-1660

Movigear combines a gear unit, motor and drive electronics in one hygienically designed unit. It's available in three sizes with torque ranges of 200 Nm and 400 Nm, and with hollow shaft and keyway or with a hollow shaft-mounting system. Voltage ranges from 380 to 500 Vac. It has LED display for operating and fault states, and integrated STO safety function.

SEW Eurodrive;

864/439-7537

Custom, direct-drive motor assemblies with ULT, UTH, UTS and UTO brushless frameless motor kits inside include precision bearings, special encoders, special mounting features and cabling to provide a low-profile, direct-drive solution. Sizes range 10-500 mm diameter with pancake profiles as low as 10 mm.

Applimotion;

916/652-3118

Two- and five-phase stepping motors/drivers, and motion controllers come in 24, 42, 60 and 85 mm frame sizes, with rated currents of 0.75, 1.4 and 2.8 A/phase, and communicate via RS-232C, RS-485 or USB ports.

Autonics;

847/680-8160

0.72° PKA Series combines motor with a built-in microstepping driver and stored-data controller for noise and vibration reduction, so there's no wiring needed between the controller, driver and motor, and no need for a pulse generator. A positioning function is built in, and they come in 42-mm and 60-mm frame sizes.

Oriental Motor;

800/468-3982

SWM24 fuses a motion controller to a high-torque, NEMA24 step motor, and is engineered to IP65 standards. All connectors are sealed, M12 style. Units provide 340 oz-in. holding torque, are available with Ethernet or RS-232 communication, and include a 4,000 count/rev optical encoder housed inside.

Applied Motion Products;

619/709-0330

D-Frame VLT drives in 125–450 hp range require less panel or wall space, and use back-channel cooling to remove 90% of the heat generated. With IP20, IP21 (NEMA 1) or IP54 (NEMA 12) enclosure ratings, they can be factory-fitted with optional semiconductor fuses, mains disconnect, contactor and circuit breaker.

Danfoss VLT Drives;

800/432-6367;

DMC-30016 combines a single-axis motion controller with a 1.4-A per phase, 30-V stepper amplifier that drives a two-phase, bipolar stepper motor in full-, half-, 1/4- or 1/16-step. It is configurable at 0.5–1.4 A per phase in 10 mA increments at 12–30 Vdc. Servo loop update is 125 ms, encoder frequency is 15 MHz, and stepper pulse output is 3 MHz.

Galil Motion Control;

800/377-6329

Brushless dc servomotor Series 0824 and 1028 are 8 and 10 mm, have high continuous torque, 1.1 and 2.1 mNm respectively, and a flat slope of the n/M motor curve. The motors can be used with a wide variety of Faulhaber encoders, gearheads and speed and motion controllers.

MicroMo;

800/807-9166

Leaders relevant to this article: