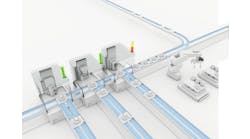

Stack lights give operators, technicians, production managers and manufacturing staff visible and audible indicators of a machine's status. They are a type of andon, which are production systems that detect problems as they happen. Stack lights are color-coded indicators that are layered on top of one another in a columnar structure to represent various machine or process conditions. A stack light typically has as many as five distinct colored segments. Independently operated segments in any combination of red, yellow, green, blue or clear white are either off, solid-on or flashing. The color-coded segments are engineered to provide a clear visual cue that provides feedback to the operator.

Also read: What do stack lights mean in the visual factory?

The colors of an indicator light are generally used to identify a process or machine status. While there are no hard and fast rules about which colors correlate to different machine states, there are generally accepted ones:

- red—any significant occurrence or state of the machine that might cause a shutdown

- yellow—any warning condition that may or may not cause a machine to shut down

- green—most typical way of expressing that the machine is in good operating order

- blue—frequently used to request help from maintenance, a supervisor or other factory floor employees

- white—machine-specific functions that are defined by the user.

If the red light is solid, it might indicate a lack of material, a jam or a failed inspection. We may now utilize the flashing red light-emitting diode (LED) to indicate machine down or e-stop activation.

If the yellow light is solid, it might indicate a lack of material, an out-of-range temperature or the presence of a manual bypass. Recovery from e-stop, safety muting active or test-in-process is now indicated by the yellow light blinking.

The green light indicates that the machine is working, that the part has passed inspection or that automated mode is engaged. When the green light flashes, the machine is ready to start or initialize. Manual mode is now operational.

The machine is either off-line or in need of service if the blue light is solid. If the blue light is flashing, you're waiting for a service call or raw supplies for an extended amount of time.

Finally, the white light of the stack light is solid for the current rate of production or when the machine service period is nearing. The machine is out of service if the white light flashes below the production rate or past the machine's servicing period.

Although there are no hard and fast rules about color, some colors are better for certain tasks. Some machines react better to particular colors, so the person designing them should take this into account.

Typically, red or yellow conditions require operator action. Blue or white conditions may also require operator action.

Productivity monitoring, uptime and downtime monitoring and machine fault management are all common uses. Stack lights give more particular machine/process status data when used in combination with supervisory control and data acquisition (SCADA) systems or human-machine interfaces (HMIs).

Choosing the proper indicator stack light for your installation is simple. A site survey of the installation area can quickly determine the best location for a unit to be placed so that it is visible to all equipment monitors.

Here are some things to consider when you are selecting a stack light. One is that stack lights come in a variety of grade levels, offering customers lots of alternatives to fulfill their specific quality and price requirements.

Although some units have metal shell housings, the vast majority of stack lights are made of plastic. Light intensity, durability, ease of use/installation and connectivity are all factors that influence stack light quality.

Second, the installed environment must be taken into account. Third, a larger unit is usually visible from a distance. Good manufacturers use the extra room inside the illuminated section to add more LEDs and boost the luminous intensity.

Fourth, I would select LEDs because they have a long life span and provide vibrant color and brightness at low currents. Also, the majority of manufacturers offer buzzers as standard equipment. Buzzers normally have a sound pressure rating of 80-105 dB and are most useful when the sound can be softened to fit the installation area. They should be irritating but not deafening to an operator.

A motion control system or a robotic work cell is more difficult to specify than a machine’s stack lights. The stack light has a very important role in the process of design. It is one of the most essential aspects that helps to determine a machine's status quickly just by looking at it.