Download the report.

A Control Design reader writes: I work as a control designer at a packaging equipment OEM, and I think my boss is being cheap. At question is whether to add an HMI or keep the half dozen indicator lights for status and fault annunciation on our box-making machine. It seems like hardware cost is the boss’ only concern, where I think integration labor, user experience and functionality are much more important. The addition of an HMI is way beyond just the bottom line cost; it's about machine capabilities and can even help to sell it. What are some pros and cons of adding an HMI to a machine that doesn't currently have one, whether on a new design, existing design or retrofitted? I plan to use this information when presenting my HMI upgrade solution to the boss.Implement very basic rules

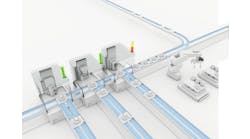

Frank A. Loria, vice president, Harry Major Machine: If component level fault diagnostics, charts or any diagrams are required on said equipment or systems, you will need an HMI, which cannot be achieved with standard push buttons and indicator lights; an HMI has great advantages for fault recoveries and expendabilities.

Standard operator push-button boxes with indicator lights are more economical when systems have four or fewer motions or eight outputs and a limited number of inputs, of course, not including the above-mentioned, and only basic motions are needed. The HMI becomes more economical when your equipment or system requires five or more motions or 10 or more outputs and a number of inputs.

Look beyond the sunk cost

Eric Reichert, product marketing lead specialist—industrial PCs and HMIs, Phoenix Contact: Weighting initial investment costs is a natural way to measure alternatives, considering this is how most consumers make purchasing decisions. However, when we make big-ticket purchases, we understandably look at total ownership costs so that we can limit buyer's remorse and fully understand our benefits/risks. When installing HMIs on machines that were previously indicator lights, it is certainly an upsell situation and may need to be justified due to the engineering required and potential issues associated that wouldn't be found with a more passive installation. However, once one looks beyond the initial sunk cost of engineering hours, they'll see the benefits that are available to them, such as remote monitoring, historical logging, user guidance and trending. These fundamental benefits can save OEMs after-sale support dollars, can provide great introspective to one's process and can also be sold as support plans that generate extra revenue to hedge against the initial cost.