Jim Montague is the executive editor for Control. Email him at [email protected].

It helps to be on the same page. Whether you're singing hymns or designing complex machines, it's crucial to have the right documents in front of the right people at the right time. But, perhaps because easy access to essential plans is so obvious, it commands less attention than flashier methods — just like singers or musicians, who focus on the 1/8 and 1/16 notes, but fall asleep and flub the easy, whole notes.

So even though putting designs at team members' fingertips is very powerful, and streamlining that access is essential for complex projects, these benefits don't often get the recognition they deserve. Nowhere is this truer than when a common design platform provides simultaneous access to a project by all its contributors; breaks down the former sequential silos separating mechanical, electrical, controls and software designers; and accelerates their interactions and problem solving for projects that must be turned around faster.

More, Better Models

Joy Mining Machinery in Warrendale, Pa., builds high-production, underground mining machinery for users who extract coal, potash, salt and other bedded materials. The 91-year-old division of Joy Global employs a variety of 3D prototyping software to develop designs for its machines, which can range from 20 to hundreds of tons and have as many as 40,000 parts. The company reports its digital designs allow its 400 engineers at 13 engineering sites on five continents to cooperate and explore innovative designs faster; meet all safety requirements for new and rebuilt equipment before construction; minimize physical changes on the shop floor; reduce costs and speed time to market; and reuse designs for manufacturing and marketing.

"Steel is very expensive, so we don't want to start welding and cutting until all stakeholders are completely satisfied with the design," says Chris Flynn, Joy's engineering systems director. "We interpret their requirements to create digital prototypes in Autodesk Inventor, and the longer we can keep design iterations in the virtual world, the easier and more cost-effective it is to experiment with new ideas. Not only is it much easier for engineers to share designs, but we also have access to many Inventor features that we couldn't use with our old product data management (PDM) system, and we transitioned systems globally without a hitch, which was a major accomplishment."

To perform all these tasks, Joy's design engineers adopted Autodesk's Vault Collaboration software and upgraded to its latest Inventor version in 2009. They also use its AutoCAD Mechanical to share designs with suppliers that rely on 2D design data, AutoCAD Electrical to design electrical controls, and its visualization software, including Maya, Showcase and 3dsMax, to create near-real images and animations. Besides evaluating physical design concepts for space, safety and performance, the visualization and simulation tools also allow Joy's designers to conduct stress analyses and simulate machine motions to find collisions and other errors that might not otherwise show up until physical production.

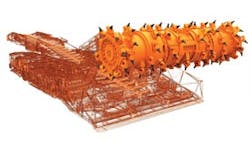

Figure 1: Joy Mining Machinery uses prototyping software to foster collaboration by its global design team members and clients and develop innovative, reliable designs, such as its 14ED entry development machine that combines mining and bolting operations.

Source: Autodesk and Joy Mining Machinery

For instance, Joy's designers recently developed their 14ED entry-development machine, which combines mining and bolting operations into one device, eliminates the need to alternate between two different machines and maximizes productivity without compromising safety (Figure 1). However, designing 14ED was a challenge because its combined functions needed three operators, rather than the usual one per machine. As a result, integrating all its functions and leaving adequate, safe spaces for operators required a lot of experimenting because standard enclosures couldn't be used. So they tested different shapes and locations during the design phase and used Inventor's Tube and Pipe-Routed Systems feature to find the most efficient way to route their hydraulic hoses.

"Hoses can take up a lot of workspace, and when they're bundled together, they can be as hard as pipe and difficult to move in the real world," Flynn explains. "By modeling hoses in the virtual world, we could experiment with the design to find routing that would give operators the space they need. It also saved us doing workarounds on the shop floor."

Cooperation to Sharing to Control

Naturally, as collaborative design and simulation tools get smarter and exchange information more widely, some observers speculate they're going to begin monitoring operations and could even do some real-time control.

Michael Schomas, vice president of technology and professional services at EPlan, says "the whole electronic CAE (ECAE) field is evolving from drawing to engineering tools that capture modular, scalable data, and then allow it to be easily shared with other users and systems. It's crucial for engineers to have unified tools that don't require them to type into Excel spreadsheets or do other manual tasks because they aren't working in sequence in mechanical, electrical, controls or software silos, and throwing completed project sections over the wall anymore.

Many engineering organizations are more like octopuses now with designers, engineers, manufacturing operations, purchasing and sales all simultaneously feeding input into central, common areas, such as our new Engineering Center platform. Working at the same time instead of in sequence means engineers can develop baselines and create about 80% of their designs almost immediately, which means sales can provide quotes quicker, and actual machine-building can begin sooner. This is why our biggest recent innovation has been data integration, which includes exporting data to manufacturing equipment, and bringing 52 partners into our data portal, so we can pull in their devices, too."

Likewise, Paul Brown, global marketing director for NX software at Siemens PLM, explains that as CAD and other tools move beyond modeling geometries and add behavioral data from sensors, motors and other devices, they begin to overlap with some monitoring and control functions. "In fact, Mechatronic Concept Designer has been part of our NX software for about two years, and it adds behavior to designs," Brown says. "This means users can take in control or motion signals, use them to trigger subsequent actions and even output code back to PLCs to close that loop."

Profile Forces, Physics<

Beyond providing more complete and accurate models, one of the most important advances in recent machine-design tools is incorporating the influence of these and other physical forces into designs. This further increases their sophistication and usefulness, and helps design engineers put their heads together faster on solving technical challenges.

Figure 2: Schaeffler Technologies used FEA software to develop a virtual prototype for performing stress analysis and strength verification of its huge new rig for testing big rolling bearings for 100-meter wind turbines.

Source: Dassault Systèmes and Schaeffler

For example, to test the extra-large rolling bearings required by the world's growing number of 100-meter wind turbines, Schaeffler Technologies in Herzogenaurach, Germany, recently designed and built a rig large enough to evaluate the bearings in real-world conditions (Figure 2). Schaeffler manufactures more than 40,000 types of rolling bearings, assemblies and related parts under its INA and FAG brands, including the two huge, spherical rolling bearings that help rotate the London Eye Ferris wheel.

However, before construction of the test rig could begin, Shaeffler needed to use finite element analysis (FEA) to quantify the rig's critical operating conditions, and to minimize its testing time and costs, according to Martin Stief, Schaeffler's CAE Integration department engineer. So Schaeffler used Abaqus FEA software, and organized a seven-member team familiar with it to design a virtual prototype that could perform stress analysis and strength verification of the test rig itself, which replicates the actual conditions rolling bearings experience inside wind turbines. Abaqus FEA is part of Dassault Systèmes' Simulia division.

The team divided the test rig analysis into smaller, manageable, functional, finite element (FE) sub-models, which then were connected together to represent the overall test rig. To ensure this global representation's accuracy, the team used its engineering judgment in defining loads, transition regions and boundary conditions, such as stiffness, mass and damping, between FE sub-models. Next, parts of the sub-models were replaced by interface conditions that could be determined by analytical or simulation-based calculations, which reduced the size of the sub-models and accelerated creation of working models.

"We used Abaqus to test the strengths of joints and to check specific connections," Stief says. "When the overall design of the test rig became clearer, we began using Abaqus on the sub-models for strength verification. From those results, we improved the test rig's design using basic mechanical engineering know-how, such as strengthening ribs by making them larger. Then we ran the sub-model through Abaqus again for another strength assessment."

Wind turbines typically run at about 16 revolutions per minute, but Schaeffler's engineers wanted their new test rig to run up to 60 revolutions per minute, which is the same as a critical excitation frequency of 1 Hz. The team's modal analysis confirmed that the first natural frequency of the rig was 13 Hz, which was well beyond 1 Hz. Next, the team ran the full FE model of their test rig through many load cases within Abaqus, which includes hundreds of types of user elements. These are subroutines that allow users to define their own FE behavior inside a model, such as replacing rolling elements of the bearings with customized user elements representing their precise stiffness. This simplified and reduced the time, effort and cost of 3D modeling and meshing each of 500 rolling elements on the test rig, and cut computing time for analysis from about five hours to about five seconds.

Likewise, geometry-based modeling helped Schaeffler's team quickly mesh variants of the whole model and its many sub-models, while scripting and other process automation techniques made modeling and evaluating results easier and faster, simplifying strength verification. Stief adds that assembly, part and instance functions in the software promoted team collaboration, especially when exchanging parts between members or replacing instances or parts where the design or FE properties were changed.

"With options for abstraction, such as mass, stiffness and connectors, we could reduce the size of the models by replacing large 3D structures with shell or beam structures, or by linking whole-model parts with the appropriate interface conditions," Stief adds.

In all, Schaeffler's test rig cost about €7 million, measures 16 x 6 x 5.7 meters, weighs 350 tonnes and can test bearings with a maximum diameter of approximately 3.5 meters. It has five main subassemblies, including drive train, loading frame, auxiliary bearing, test bearing and tensioning frame. Its eight radial and axial cylinders replicate real-world loads.

"FEA helped us determine the lifetime of larger bearings more exactly," Stief adds. "We can now design precisely the size of bearing required by a particular turbine geometry, which helps keep costs low. The simulation models we created proved our large-size bearing test rig reliable and applicable for all types of large-size bearings. In the future, simulation validated with test rig runs will give Schaeffler bearing-specific values, such as load distribution, pressure distribution, contact angles and data about the elastic behavior of bearing components under high preloads. "This will lead to even more realistic results in bearing lifetime calculations," he adds.

Elaborate on Electronics

But what if you're not enormous enough to staff and feed you own design team? Well, then outside assistance is available. To help smaller machine builders streamline control panel designs, Design Ready Controls (DRC) in Minneapolis says it's an original design manufacturer that operates as an extension of its OEM clients. These include Valent Air Management Systems, also in Minneapolis, which builds rooftop ventilation and refrigeration units.

In the early stages of a planned product family, DRC assimilates Valent's design requirements, and uses its proprietary Automated Panel Expert (APE) configuration software in conjunction with computer-aided engineering (CAE) software such as EPlan's Electric P8 and its engineering macros to configure and automate design tasks, generate cost estimates and produce more varied components. Operating within APE, Valent's engineering and marketing experts can choose from a list of design-ready options that are web-based, interactive and customizable.

"With EPlan's advanced storage capabilities, we don't have to program each individual aspect of a circuit, such as wire gauge and protection sizing," says Dipesh Karki, DRC's senior programmer and software architect. "Previous generations of APE took many months of programming to create the engineering documentation required to build and wire the panels."

However, Karki adds, the real power of its collaborative design process is that APE and Electric P8 enable OEMs with highly variable equipment and controls — like Valent — to skip the traditional, manual engineer-to-order (ETO) process. DRC overcomes these old bottlenecks by using APE and Electric P8 to automatically generate drawings for just-in-time production of its control panels and wiring harnesses.

"By using APE's system engineering rules and EPlan's macro libraries, our entire ETO process is automated," says Mitchell DeJong, DRC's R&D director. "This system anticipates and processes component selection, part sizing and functional requirements automatically."

In addition, APE uses EPlan's flexible application programming interface (API) extension to electronically digest orders and feed Electric P8 a complete set of design instructions for each unique panel. By employing this instruction set and its own placeholder object and macro-variant technology, Electric P8 can pick, place and size necessary devices, component parts and wires into a complete set of schematics and layouts. Consequently, DRC can diagnose drawings for accuracy and generate manufacturing reports such as interactive PDF schematics and bills of materials linked directly to ERP systems. DRC adds this automation reduces order turnaround time, often from weeks to minutes, adds integrity to its panel engineering and feeds all information to its manufacturing staff.

Similarly, LE80JV in Ascot, Western Australia, is a joint venture between LogiCamms and Electro80 that implements electrical and control systems engineering projects. It decided to move from CAD to intelligent design drawing software when it was hired a few years ago to streamline the designs of two mineral sands mining and zircon processing projects for Iluka Resources in Victoria and Western Australia.

The first mine project in Murray Basin only had an 18-month schedule, so LE80JV decided to use promis•e electrical design software from Bentley Systems, which had an API that automatically generated schematics, connection diagrams and cable schedules, and allowed users to easily change designs and check results. LE80JV also used the API to design and automatically generate all designs for the second project at the Jacinth Ambrosia mine. In addition, promis•e automatically performed identification assignments, wire numbering, cross referencing, error checking and report generation; produced drawings in Iluka's preferred DWG format; and automatically created drawings from templates.

Thanks to the 2,000 drawings that promis•e produced, the Murray Basic project was completed in 12 months. And LE80JV used design content from the first project to finish the second at Jacinth Ambrosia in weeks instead of months. In all, LE80JV reduced engineering and drafting hours on the projects by 25%, cut drawing checking time by 70% and cut Jacinth Ambrosia's upfront engineering time in half.

To further preserve users' resources, Bentley reports it offers a flexible licensing strategy, which gives users access to promis•e and its other software tools for only as long as they need them. If users need access to all of Bentley's tools, they can sign up for its Enterprise License Subscription (ELS).

Organizing Variety, Teams

Of course, once collaborative tools let designers develop more complex and capable devices and end users see what they can do, then the variety of components and potential end products also begin to snowball. So while collaboration is the prize, it still has to be carefully organized to have the greatest, positive impact.

Figure 3: ICA design and builds custom machines and control panels and uses PLM software to increase design accuracy and reduce rework.

Source: Siemens PLM and ICA

For example, Industrial Control Associates (ICA) is a system integrator and machine builder in Pine Mountain, Ga., which provides design, engineering, construction and start-up support services for its custom-built machines and control panels (Figure 3). It also delivers electrical and mechanical installation, turnkey integration, custom robotics, motion applications, machine modifications and nondestructive testing.

Even though it only has eight employees, ICA projects a large-company image, competes against much larger firms and wins orders from companies such as Magna, Voight Aircraft, Citation, Cooper Tire & Rubber, DuPont, P&G and Tyson Foods, according to Brian Hare, ICA's CEO. He adds that a key element of its large-company image is using PLM software such as Siemens PLM's Solid Edge software for accelerated design and Teamcenter software for collaborative decision support.

Hare reports that ICA has used Solid Edge software for nearly 10 years, and adds it increases machine design accuracy and reduces rework. "Prior to Solid Edge, our remanufacturing rate was 20%," Hare says. Now it's only 2%."

The software also helped ICA cut the time it takes to complete machine-building jobs by 33%, but Hare expects to save even more time as ICA increases its use of its synchronous capability. "When we design testing machinery, we need to use the customer's assembly data, no matter what system it was designed in," he explains. "By allowing us to bring in and work on data from any CAD system, Solid Edge's synchronous technology will save us the time it takes to redraw that geometry. By doing small design tests through parallel work in synchronous technology and traditional modeling, we've seen as much as a 30% reduction in the design phase, and we expect that number to increase as we get further along the learning curve."

Also, ICA is using Teamcenter to better organize work revisions, releases and information, such as Solid Edge-related data, customers' AutoCAD drawings, PDFs, quote documents, conceptual drawings, pictures and background material. With one product data repository, searches that used to take 10 minutes can now be done in 30 seconds. And, using Teamcenter's workflow function, ICA has started automating its paper-based processes, which helps ensure compliance with best practices and regulations.

Animate Customers, Too

Understandably, after fostering in-house cooperation, some machine builders use digital designs to work more effectively with their clients. Hare adds, "Teamcenter's visualization capabilities make it easier for customers to view an assembly. This can be done in 30 seconds instead of 30 minutes using CAD."

Hare envisions holding frequent mini-design reviews with customers throughout the design process. "We're looking forward to letting our customers look at designs at key times, so that they understand what they're getting early on," he explains. "They've never had that ability to look at something before seeing the approval drawings, and it has caused substantial waste. With Teamcenter, they can see early on if we're going in a wrong direction and raise a flag. Its web-based collaboration tools make this possible no matter where the customer is located."

Joy Mining Machinery also reports its 3D prototypes help clients understand machines before they're built, and adds it's even using animations to bring some designs to life. "We can interact more effectively with customers at earlier stages of development using Autodesk's Digital Prototyping," Flynn says. "The best part is we can capture customer changes before we start cutting metal, thereby reducing costs and speeding manufacturing."

Flynn adds that Joy recently needed customer approval for a radical, new design and used digital designs from Inventor along with Maya and 3ds Max to develop a movie about the machine's movements and operation. "The feedback we got on the movie helped us pinpoint the ergonomic and minor operational changes we needed to make," Flynn says. "It was instrumental in helping us meet our customer's needs."

Brown adds that Siemens PLM's NX software is even taking a page from PC gaming, so users can make designs more real and useful to collaborators. "Traditionally, CAD represents mechanics and motion, and defines things like joints and limits, but it didn't represent forces like gravity very well," Brown adds. "However, gaming engines have many gravity effects, and so we're incorporating tools from Nvidia's graphics card toolkit into our NX software to better simulate real-world behavior and timing."