How to choose machine motor type: upfront cost vs. maintenance vs. efficiency

A Control Design reader writes: We build custom machines for consumer packaged goods (CPG) manufacturers. Across the board, they use a variety of brushed and brushless motors to power many different machines, from vertical and horizontal packing machines, form-fill-seal machines, wrapping machines, and pouch filling and sealing machines. For some with smaller maintenance teams, they prefer brushless for less maintenance. Some prefer cheaper brushed motors, and they rarely set a production line and forget it and are mostly available for regular maintenance. In general, we let customers choose the motor type they prefer, but lately, we’re getting more questions about how to make motors more efficient. Are brushless motors always the more efficient option? Does that efficiency match the added cost? Are there ways to design with brushed motors that makes the machine more efficient? And what about their conveyor systems? Can motor design add efficiency there?

No one-size-fits-all motor

Selecting the best motor type for an application can be confusing, and for good reason, as there are many factors to consider. In the most straightforward applications, motor types typically have specific use cases that they excel at:

· brushless dc, and some dc: precise motion, servo control, coordinate motion

· stepper: indexing, discrete positioning applications, constant load.

Many machines will use more than one motor type, depending on the axis. But as different users have different priorities, short- and long-term, there is often no one-size-fits-all. Increased automation is also an emerging factor, with the Industrial Internet of Things (IIoT) now promising process efficiency gains and lower costs. Making a motor part of this is increasingly critical, steering selection of motor type.

Let’s look at some options. There are many more, but these are the main ones that might be considered in an industrial process:

· ac/dc universal brushed

· dc brushed

· induction

· brushless dc (BLDC).

Figure 1 shows the basic differences between the motor types, but we can unpack this a little more.

The universal or ac series motor includes brushes for commutation, and, in the high-speed, high-power applications it matches, frequent maintenance is needed (Figure 2). For this reason, they are not typically employed in continuous-use applications. If the conveyor-belt application mentioned has frequent stop-starts and heavy loads, it might be a good choice as it has high-starting torque. The motor is relatively lightweight, and electronic speed control can be achieved with a thyristor chopper, for example. However, the motor will naturally slow with increasing load unless speed sensing and feedback to the chopper are included. Also, noise and interference levels can be high from sparking at the brushes.

DC brushed motors are low-cost and simpler than universal types but also have maintenance, noise and interference issues (Figure 3). For efficiency, they are overall a little better than a universal type, and speed control with a chopper or even external resistors is possible. You need a dc supply, and polarity sets the rotation direction. These motors are used mainly in products like hand tools, but high-power versions are used in cranes and battery-powered lift trucks, for example. If a brushed motor is chosen, the point of best efficiency might be at 20% of maximum torque and 40% maximum speed. Performance curves will show this, and choosing a model that is overrated could save significant energy over time.

An ac or induction motor is the workhorse in industry (Figure 4). It doesn't need brushes so is simple, quiet and almost maintenance-free. This, along with low initial cost and relatively high efficiency makes its lifetime cost modest. The downside is that it operates at a fixed speed, set by the ac supply and number of motor poles, making the motor type most suitable for loads such as fixed-speed fans and pumps. Single-phase types need starting arrangements—typically capacitors, which can fail—but three-phase types self-start. In the conveyor application, if it is in continuous constant-speed operation with light loading, the induction motor would be a good choice.

Augusto Panecatl, GCET analog and power applications engineer / Avnet

Cost vs. maintenance

When considering whether to use brushed motors or brushless dc motors, there are multiple considerations. Brushless motors typically offer the best performance, flexibility and service life. There is no getting around the fact that brushed motors require a physical contact between the rotor and the stator in order to transfer power. The physical contact of the brushes creates friction that does not exist in BLDC motors. And this additional friction typically has adverse effects like reduced performance, lower efficiency, shorter service life and noisier operation.

This is a noteworthy list of advantages for BLDC motors. Given that, why do machine builders still use brushed motors? The answer is simple. Brushed motors offer a compelling lower price. The upfront costs of brushed motors are significantly lower than a comparable BLDC motor. This means machine builders who don’t require the advantages of brushless motors can use brushed motors and reduce their upfront costs. And vice versa.

Let’s add one consideration: the cost of maintenance and downtime. Brushed motors typically have a reduced service life, and they require downtime to replace the brushes or to replace the motor. For some end users, this downtime will not cost them significantly. Consider an end user that is running its production for one or two shifts and has downtime on a regular basis. If they have a maintenance department, the cost of downtime may not be significant. However, for an end user that runs its production line around the clock and doesn’t have a maintenance department, the loss of production time can be quite expensive.

Taking all of these considerations into account, it is clear that machine builders who require motors with improved performance, efficiency and service life should use brushless dc motors. There is simply no way to achieve the same level of performance with brushed motors. And machine builders who do not require these advantages should consider brushed motors, keeping in mind the lower upfront costs, as well as the overall equipment efficiency and costs of downtime.

Tom Worsnopp, product market manager, electric automation / Festo

Brushed vs. brushless

Standard dc brushed motors were originally used when full torque was required at lower speeds, and it was desirable for the speed control to be inexpensive and simple. In the past two decades, as ac motors have become more efficient and flux vector ac variable-frequency drives (VFDs) have become affordable, it makes much less sense to use dc brushed motors in many applications where a modern ac motor and VFD will provide better performance and reduced maintenance.

DC brushless motors offer better performance than dc brushed motors, and much improved lifetime and minimized maintenance. However, dc brushless motors generally involve a much higher initial investment in the motor and controller. While they are more efficient than other types of motors, it can be hard to justify replacement based strictly on efficiency. Reduced energy use must be considered in light of the size and application and combined with the value of reduced downtime and minimized maintenance labor/parts. Therefore, the decision really comes down to the business constraints, the market and end-user demands.

Kevin McClelion, product manager/ AutomationDirect

Brushless dc motors are more efficient

Brushless dc motors are generally more efficient than brushed motors. They were actually developed in 1962 by T.G. Wilson and P.H. Trickey, who created a brushless dc motor that used electronics for commutation, eliminating the disadvantages of using brushes and offering the capability of higher torque-to-weight ratio and greater efficiency.

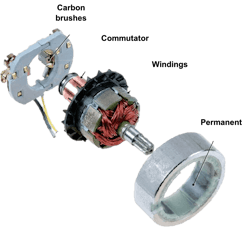

By contrast, brushed motors have been around since the 1740s and have been widely used on a commercial basis since the 1880s. For brushed motors, the polarity of the current needs to be reversed every time the motor turns through 180° to keep the rotation in the same direction. Brushes make contact with a split commutator, enabling the change of direction of current flow. The mechanical contacts provided by the brushes, however, result in the generation of significant electromagnetic interference (EMI), sparks and reduced lifetime due to erosion of the brush and commutator.

The BLDC motor uses a rotor with permanent magnets and a stator comprising of electromagnets whose polarity is switched electronically to drive the rotor. They can be constructed in single-phase, two-phase and three-phase configurations, with three-phase being the most popular.

BLDC motors are used in a wide variety of applications, from flight and car simulators to ceiling fans. Today, BLDC motors are generally the preferred technology, improving the performance of anything from computer hard drives and industrial robots to electric vehicles.

Simon Meadmore, vice president, product and supplier management / Newark

About the Author

Anna Townshend

Managing Editor

Anna Townshend has been a writer and journalist for 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, until she joined Endeavor Business Media in June 2020. She is the managing editor of Control Design and Plant Services.

Leaders relevant to this article: