A Control Design reader writes: As a controls engineer at a large manufacturer, I've been tasked with reducing the number of spare parts we keep on hand. One of the areas that we have a vast array of spares is stepper and servo motors and the related drives/amplifiers—and they are difficult to support. These spares are for motion-control applications on our plant floor that range from simple conveyors and single-axis motion control to x-y-z gantries, multi-axis coordinated motion and vision-guided motion.

Best practices for motion control are important to discuss and consider, but isn't there a "family" of stepper or servo motors and drives that will work with a wide range of applications? It's more than spare-part reduction, I want to simplify development, programming, integration and support. I'd just like to connect the controller to the drive via EtherNet/IP or similar; interface to built-in drive safety; use closed-loop positioning; and control the motion with similar functions and methods. I want to do more with less variety of control hardware; how do I do that?

ANSWERS

There’s complication in numbers

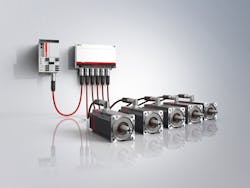

With such wide-ranging motion control tasks, limiting the number and variety of servo and stepper drives and motors on hand is bound to present challenges. Component selection for any machine depends on performance, cost considerations, form factor, fieldbus and controller options and even heat output, among other factors (Figure 1). In addition, as the number of motion-control devices increases, so can the number of software platforms and interfaces for programming and configuration. All of these factors combine to complicate ongoing support, maintenance and spare-parts management.

Figure 1: Component selection for any machine depends on performance, cost considerations, form factor, fieldbus and controller options and even heat output.

Our broad drive technology portfolio includes scalable servo and stepper solutions for any application requirements. These cover every application from compact motion to multi-axis coordinated motion. Axis modules directly connect via a tool-free pluggable connector system, greatly reducing cabling and connectors. Compact I/O devices as small as 12 mm wide are also available with built-in drive functionality. These DIN-rail- or machine-mountable drives greatly reduce enclosure space requirements and eliminate much larger amplifier hardware.

Drive manager software allows users to export and back up drive configuration if desired, and it also supports importing of configuration files. Communication via the EtherCAT industrial Ethernet system enables fast and highly synchronized motion control. EtherCAT can serve as the all-purpose fieldbus, covering all aspects of motion control, I/O, safety and more. Systems networked via Profinet or EtherNet/IP can still utilize EtherCAT-based drive solutions using gateways or devices that directly support the Profinet or EtherNet/IP on the front end and EtherCAT on the back end for true synchronization of the drive system. Users can have direct motion control from the Profinet or EtherNet/IP client device, allowing them to access a compact and reliable servo and stepper drive system.

MATT PRELLWITZ / drive technology product manager / Beckhoff Automation

Servo and safety

Servo drives and servo motors offer machine manufacturers the greatest flexibility. Whether it’s using a servo drive with different third-party controllers or using a drive with third-party motors, servo drives can help accomplish your goal to do more with less variety of control hardware for a wide variety of applications. Integrated safety is available with servo drives. Plus, there is an array of available program function blocks for specific motion profiles.

Servo drives offer a broad option of communication protocols. With a multi-encoder, the servo drive can support Sercos III, Ethernet/IP, EtherCAT and Profibus so it can be connected to any controller with these communication protocols. The advantage is that there is no need to order separate part numbers for different servo drives with distinct communication protocols. The same part number supports all the communication protocols, reducing the bill of materials (BOM) even when using various controllers.

In addition, servo drives have a multi-encoder interface that supports several encoders and can support third-party motors with the following encoders:

- ACURO link

- Hiperface

- EnDat 2.1, EnDat 2.2

- 1V p-p

- 5V TTL

- SSI

- sin/cos

- resolver.

The servo drive can also be used as open loop for third-party motors, thus reducing the BOM since the same drive can be used for an assortment of third-party motors.

Safety for the operators should always be the primary concern. With integrated safety in the servo drives, not only is safety for the operator increased, the safety of the machine is taken into consideration and productivity is increased. Servo drives can support the following safety protocols and allow the use of various safety controllers:

- CIP Safety on Sercos

- CIP Safety on EtherNet/IP

- ProfiSafe on ProfiNet

- Safety over EtherCAT.

The servo drive can offer safe-torque-off and SafeMotion up to Cat. 4, PL e, according to EN ISO 13849-1, and SIL 3 according to EN 62061. It supports the following safety functions, making it the most flexible servo drive with safety options for machine manufacturers:

- STO—Safe Torque Off

- SBC—Safe Brake Control

- SS1—Safe Stop 1 (time- or decelerated monitored)

- SS1-ES—Safe Stop 1—Emergency Stop (time- or decelerated monitored)

- SS2—Safe Stop 2

- SOS—Safe Operating Stop

- SCO—Safe Communication

- SIO—Safe Input / Output

- SLS—Safely Limited Speed

- SDI—Safe Direction

- SLI—Safely Limited Increment

- SMS—Safe Maximum Speed

- SMD—Safely Monitored Deceleration

- SLS-LT—Safely Monitored Oscillation

- SZA—Safe Zone Acknowledge

- SZE—Safe Zone Error

- SDL—Safe Door Locking

- SMP—Safe Monitored Position

- SLE—Safe Limited End position

- SLP—Safe Limited Position

- SCA—Safe CAM.

In intelligent drives, the control-loop structure can be open-loop axis control, torque/force control, velocity control or position control. In position control, there are options for position control with cyclic command value input, drive-internal interpolation and positioning modes (drive-controlled positioning, positioning block mode) to assist in creating motion.

Flexible and scalable servo drives help to make the machine manufacturer’s job easier. Whether it’s reducing the BOM or saving engineering time getting the machine to the end customer, servo drives will help accomplish the goal of doing more with less variety of control hardware across a wide range of applications.

JOAQUIN OCAMPO / product manager, automation and electrification / Bosch Rexroth

Consider application requirements

The most obvious way to reduce part count and simplify development, programming, integration and support is to migrate to an integrated motor platform that offers NEMA standard motor mounting. Integrated motors fuse a servo or step motor with a drive, control components and closed-loop feedback sensor into a single device. Integrated motors offer a space-saving design that reduces wiring and can provide cost savings over separate motor, drive and control components.

Most integrated servo and stepper motors feature distributed fieldbus support for network connectivity and offer a single programming interface for setup, tuning, motor control and motion control. Additionally most integrated motor manufacturers have developed a universal programming environment that allows users to seamlessly switch between servo and stepper integrated motors without having to redo the bulk of their code.

By using integrated motors with NEMA standard motor mounting, quick changeovers are possible since the number of SKUs would be limited to the number of NEMA frame sizes— NEMA 17, NEMA 23, NEMA 34, NEMA 42—used in the machinery. This also eliminates the bothersome conversion of metric to imperial mounting using mounting adaptors and motor shaft machining.

Other important benefits of integrated motors include:

- simple installation; fewer components to connect

- reduced part count; longer mean time between failures (MTBF) and a reduction in component failures

- faster commissioning; less wiring means reduced development time

- elimination of EMI/RFI noise from long motor cable runs

- lower cost; no need to install a separate servo or stepper drives or controllers in a control cabinet.

There is, of course, a trade-off to using integrated motors. Many motion applications require specialized motors, such as coreless motors, frameless motors, slotless motors, flat motors or low inertia motors, for unique applications, and not all integrated motors offer the characteristics of a specialized motor. The same applies on the control side; there may be a feature available in a servo or stepper drive that is critical to the success of the application but may not be available in an off-the-shelf integrated motor.

Ultimately the choice to switch to an integrated motor platform depends on the application requirements of the machine.

WARREN OSAK / president / Electromate

Start with the design

I completely understand your challenges as I've designed, built and supported a lot of motion-controlled machines. It's hard to standardize spare parts as the motors, drives and cables are usually only compatible with a single product line of a brand. The range of applications in the facility makes the problem even more complex, and the challenge isn't just about the inventory. Maintenance staff has to be trained on the various brands, and there's application software that needs licensing. The solution, therefore, starts with the design. The goal would be to select a motion product line that accommodates a wide range of applications and also simplifies the design, integration and support of the system.

I'd recommend you consider a product line with a diverse selection of servos and flexible drives that will allow for fewer spare parts plus a standardized software system. In addition to this basic motion line, look for a broad range of robotic solutions including six-axis, deltas, quads, gantries and a versatile line of collaborative robots. If you have to have the flexibility of both servos and steppers within one family, then consider an offer that allows for a selection of both servos and steppers under one brand, but it may require more specific drives and additional integration. Overall all there is not one perfect product line for industrial motion, but a plant can be made leaner and easier to manage by starting with the design and driving standardization.

JIM DAVIS / director of advanced solutions & technical support / Allied Electronics & Automation

Common interface, configuration variety

Yes, this is the all-in-one drive concept—one set of electronic hardware to drive a multitude of motor types and configurations. The concept could fairly easily be expanded to a limited set of electronic hardware if expanded electrical ratings are required to drive larger motors.

The idea is to provide a common interface/electronic hardware to drive a large variety of motors and system configurations.

MIKE TETMEYER / engineering lead research/development / Haydon Kerk Pittman

Remember maintenance

Choosing the right motor is critical for the efficiency and productivity of your motion control applications. It can be difficult to choose between servo motors and stepper motors as there are so many considerations: cost, torque, efficiency, speed, circuitry and more. Both stepper motors and small servo motors offer increased versatility. Servo motors are more dynamic, packing up to three times more torque than steppers. But steppers could be an effective alternative for those considering costs as they are less expensive. As a general rule, it is smart to select a slightly oversized motor for your application. You might save some money up front with a smaller option, but slightly oversized motors generally provide extra capacity and a longer lifespan over motors that are undersized. In this way, you’ll have more flexibility and a longer system lifespan. You also should be able to use the same motor for different applications.

Proper maintenance is quicker and cheaper than any repair or replacement, so take advantage of routine maintenance programs. By allowing technicians to fix problems before they grow more serious, you’ll be saved from stress, expensive bills, work stoppages and motion-control-system replacements.

DANIEL WEISS / senior product manager / Newark

Size up

A machine’s maintenance needs should be considered during the early stages of the design cycle to ensure that the machine can achieve its maximum possible running time. Put into practice, this means being able to estimate component life, keep correct spares in stock and troubleshoot any shutdown to discover the particular failure that caused it.

Since the reader brought up spare parts, we’ll concentrate on that topic first. During design, and specifically during the sizing and selection of the servo motors, spare parts can be reduced. Most manufacturers have a wide range of motors to select from, as do we. When motors are similar in size, one can reduce spares by moving up a size on some of them.

A gantry, for instance, may have similar-sized motors. I’ve worked on some that have 200-W and 400-W motors on different axes. These motors have the same frame size, and they bolt on identically, although the 400-W motor is slightly longer. If you move the 200-W motors to 400-W motors, there’s a slight price difference between the two, but you save on stocking 200-W spares.

Staying with a gantry system, we see more customers now moving toward absolute encoders, for which most manufacturers need a battery to maintain the multiturn position. Some of the newer motors have a design that now eliminates that battery, thereby saving a potential maintenance item and a spare part.

By choosing the right family of servo drives and motors, one can perform many applications, but the controller can vary in complexity. Using some industrial networks can allow a customer to choose the best controller for the application and keep using the same family of servos to reduce spare parts top stock (Figure 2). EtherCAT is a popular open network that lets the customer choose a controller that’s best suited for a given machine.

Figure 2: Using some industrial networks can allow a customer to choose the best controller for the application and keep using the same family of servos to reduce spare parts top stock.

These same networks can sometimes run safety. EtherCAT can run safety on the same Cat. 5 cable that’s responsible for motion control. If a safety-rated drive and motor are then put into the system, a customer can achieve safe limited speed, safe direction, safe position and the like. If selected correctly, the products can all be programmed from one software package so that a single file can be maintained for revision control and future upgrades to the machine.

A complete solution can also help the customer maintain the highest operational efficiency while running the machine. As an example, if the controller, HMI and servos are from the same company, they might have built-in troubleshooting for the overall solution. This means that if a servo drive faults out, the operator and maintenance personnel can see the drive fault on the HMI and start troubleshooting right away. In some cases, the parameters in the drive can be stored in the controller to allow downloading to a new replacement drive without a laptop. This helps get the machine back into production more quickly.

Finding a family of controllers that can program from a single software package can save significant amounts of time and maintenance on the engineers’ computers. By utilizing a well-designed family, an engineer can choose either a simple point-to-point controller with very few servo axes or a highly complex controller that can run specialized functions such as G code, multi-axis interpolation and advanced vibration suppression to raise machine throughput. Using the right controller family up front can save both time and money over the entire life of the machine.

The reader also brought up vision-guided motion. This is a critical area that can become very time-consuming to get up and running if the camera, motion controller and servos are not compatible. Choosing the correct vendor or vendors up front is essential.

GREG DIECK / product manager, motion / Omron Automation Americas

[javascriptSnippet ]

Best practices

Motion-control products have large numbers of SKUs for a couple of reasons. Understanding the reasons can help you choose the SKU reduction strategy that best suits your goals and applications. Consider some of these best practices.

Motion product pairing: The right size of drives, motors and cables are paired in order to reach optimal performance. For example, drives and motors have similar continuous and peak performance curve results in better efficiency and precise control. Creating these optimized pairs often results in specialized parts for the pairings.

Some motion control companies develop product as individual components, while others design and test as a system to provide optimal performance. Servo drives, motors and cables can be designed and tested as a system. However, the motors and drives can be designed with the flexibility to be paired across sizes. Additionally, if the application requires a few different sizes that are relatively close, you could upsize the drive or the motor to meet the largest part of the application, reducing the variety of drives and motors.

Product configurations: Although there are some compliance standards, such as IEC and UL, mechatronic and motion performance is complex and often purpose-built for the application. For example, servo motors that are close to-the-machine mechanics have a larger number of SKUs because they need to accommodate for variables such as flange size, shaft, brake, inertia and feedback.

Another best practice for reducing SKUs is setting common requirements for machines coming into the facility. A common control or power architecture will by its nature help to reduce the potential proliferation of SKUs in your storeroom. Although some components, such as motors and cables, do have a large variety of configurations, some configurations can be selected to cover others. For example, multi-turn encoders can always function in a single-turn application. The shaft key can be selected to cover smooth key, a brake motor can function as non-brake motor when the brake is not engaged and a longer cable can replace a shorter cable.

This method can even be applied to servo drives. For example, a safety drive can always fulfill the functionality of a non-safety drive. Defining a standard that allows a smaller number of parts to cover more of your application will greatly streamline your storeroom.

If you are considering a long-term motion-control strategy, look for a solution that is holistic from the software to the gearbox. Finding a solution that is versatile, easy to configure and designed for your environmental needs will help you to save space in your storeroom and potentially increase productivity by reducing downtime. Choose a portfolio or family that offers safety, network capability and a wide power range that is configured from one environment. By providing safety, either network based or hardwired, into the motion products, you can be sure to deliver a safer solution to your teams without the potential of additional safety hardware. Network capable drives and amplifiers allow you to command motion from a single location, while reducing wiring costs as the added benefit of collecting machine performance metrics over the network. Additionally, having one configuration and programming environment will streamline commissioning and troubleshooting since it’s all in one place. By taking the appropriate steps in reviewing your motion-control needs, you can simplify your spares and reduce machine downtime with standard hardware from a portfolio that gives you flexibility, scalability and simplicity.

WENDY DU / product marketing manager / Rockwell Automation

SCOTT OAKLEY / controllers and IO manager, North America / Rockwell Automation

Keep it simple

Choose an automation company that can cover a wide range of control systems able to interface with all disciplines of motion control. Having a single source for your motion control needs that can support current technology and future technology for increased capacity or additional production lines is ideal. Systems can then be added, or modules subtracted, based on production demands. You can phase in this new technology using your existing hardware and develop the new systems; most often the only change would be the communications protocol, which will then become standard.

Instead of warehousing spare parts, rely on your distributors to warehouse your key components. Consider an automation company with an international presence, as well. If the local source does not have it on hand, the components can be pulled from the international distribution network. Maintenance can be predictable now with the advancement of monitoring devices that alert supervisors or maintenance managers of a potential failure such as higher current draw in motors. This may indicate mechanical stresses that could potentially lead to failure or unexpected shutdown. This will give the managers time to procure necessary replacement parts or allow scheduled downtime to perform maintenance.

Data intelligence constantly monitors, records and analyzes your processes. Industrial communications allow for controlling complex machine operations and entire production lines. Industrial security ensures production lines are as safe as possible. Safety integration reliably protects your workforce. Having a control system that can monitor your plant floor, indicate production lags, and allow remote interface will help supervisors have a grasp on what is happening in real-time.

Having a wide range of mechanical components to work hand in hand with electrical control components also simplifies installation and implementation. Most often optimal control settings are built into the software and controllers or can be auto-tuned. Programming PLCs, motion controllers and HMIs can be done with one software package.

To simplify development, programming, integration and support it is important to have hardware and software components from the same manufacturer.

This makes integration into any real-world application easier and commissioning time less stressful.

Timelines for startups are usually narrowed by the time electrical/programming/integration occurs, so simplifying commissioning is key. Maintaining these systems becomes easier with the ability to constantly monitor system imbalances leading to predictive maintenance.

Having one supplier for all these items and expertise and support in every discipline simplifies integration and commissioning. Having a wide range of motion systems with different manufacturers can be difficult to maintain. Differing programming languages, communications cables, software version control, updates to operating systems and updates to newer hardware models makes it difficult to maintain these systems. Having control structure that is uniform across all platforms makes life much easier.

WERNER LAMBERGER / technical support engineer / Automation24