A Control Design reader writes: We continue to automate our packaging operation, adding another articulated arm for machine tending and now an autonomous mobile robot (AMR) for versatile transport and conveyance. To be honest, I think the AMR was added because we had an outstanding year and our CEO has wanted one for quite some time, even though we already have two automated guided vehicles (AGVs). But I’m sure its applications will prove profitable at some point.

My concern is with safety. As more robots enter the same workspace as our employees, how do we keep our people protected? Are all robots collaborative now? Does an AMR require different precautions than an AGV? And what type of presence sensing is best for these applications—photoelectric sensors, ultrasonic, inductive or capacitive proximity switches, safety interlock? Is there a master sensor that can detect people and parts and communicate the difference to our robotic components?

Also read: AMRs give legs to fixed-point robots

Answers

Application determines collaboration

First, it’s great to hear that employee safety is a top priority. Typically, further automation is added with only productivity in mind. However, creating safe productivity should be the real goal.

The most well-proven approach to achieving and maintaining acceptable residual risk in the workplace is to start with the risk-assessment process. When properly applied, this approach identifies potential risks arising from the combination of tasks and hazards. Based on an estimation process, the inherent risk identified can be evaluated to determine if the risk is acceptable. When the risk is substantial, the results of the risk assessment should be used as a guide through the risk-reduction process, as well as measuring stick for final validation and verification that the risk reduction measures applied achieve the intended results. This process can be applied to any type of machinery, including robots, AGVs and AMRs.

While most new robots available today have features that can be used in collaborative applications, no robot is by itself collaborative. In fact, the specific application of the robot, including the end-effector, workpiece and supporting equipment, as well as intended interactions with operators, will determine if the robot system is a collaborative application. In these cases, different approaches can be applied to achieve an acceptable level of residual risk.

Figure 2: Electro-sensitive protective equipment such as light-detection-and-ranging (LiDAR) scanners have been used to detect obstruction before making contact.

People often tend to think that only robots with collaborative features, like power and force limiting, can be used for collaborative applications. However, even more traditional robots without collaborative features can be applied in collaborative applications that provide a high level of safe productivity.

Guidance is available in industrial safety standards such as ANSI/RIA R15.06-2012 (national adoption of ISO 10218-1:2011 and ISO 10218-2:2011), as well as RIA TR R15.606-2016 (national adoption of ISO/TS 15066:2016).

When it comes to mobile platforms, the same general requirements apply but based on different standards. AGVs should be designed according to ANSI/ITSDF B56.5-2019, whereas AMRs deployed in industrial settings, so-called industrial mobile robots (IMRs), should follow ANSI/RIA R15.08-1-2020. Internationally, the standard ISO 3691-4:2020 may be used. In all cases, some form of collision avoidance is required to minimize risk of injury due to contact with people. Of course, there are many other requirements found in these standards with varying degrees of similarity or differences.

Historically, pressure-sensitive protective devices—safety bumpers or safety edges—were applied to AGVs to detect contact with a person or object in the direction of travel (Figure 1). However, these devices would not initiate a stop until first contacting the obstruction.

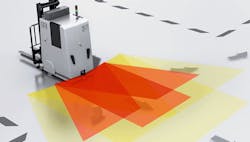

More recently, electro-sensitive protective equipment such as light-detection-and-ranging (LiDAR) scanners have been used to detect obstruction before making contact (Figure 2).

Figure 3: AGV safety laser scanner can be rated for outdoor use.

Many of these sensors also allow for dynamic switching of the detection zone relative to the current condition of the equipment—for example, different detection zones used when traveling straight versus turning or modifying the detection range relative to the speed of the mobile platform.

Recent advances have also introduced new features, such as:

- different size sensor to accommodate smaller mobile platforms

- a wider variety of performance levels to better accommodate specific applications with different levels of risk

- safety scanners now rated for outdoor use as automation advances beyond traditional factory walls (Figure 3)

- features that use the same sensor for both safe detection of people and navigation and positioning of the mobile platform.

In the end, there are many different sensor technologies available for a wide variety of use cases. It is always best to consult with an expert to find the right solution for your application.

Chris Soranno / safety standards & competence manager / Sick

Intrinsic safety

Congratulations on your company’s outstanding year, and the opportunity to adopt additional automation while enhancing your skills with advanced automation. The good news is most mobile automation providers include controls onboard that intrinsically help ensure operational safety. Furthermore, the International Organization for Standardization (ISO) is in place to help regulate safety and ensure standards are in place.

While the ISO safety rules make no distinction about vehicle category, they do outline the requirements that all machinery must comply with to operate safely. Photoelectric sensors are most prevalent in mobile automation; however, other sensor types are also used by various suppliers, with some vehicles using multiple different device types.

In general, an obstacle is an obstacle, and the sensors are there to avoid and protect the obstacles, including your employees. Since not all automated vehicles are the same, it’s important to work with an automation partner you trust that can guide you in the right decisions for your employees, your customers and your business.

Most recently, advancements in artificial intelligence (AI) have allowed automation providers to simulate how AGVs, AMRs and people can work together in a space. These tests can bring peace of mind as you introduce new technology, making sure that automated vehicles, robots and, most importantly, your employees are working safety and efficiently.

Kevin Heath / senior robotics manager / Dematic

Not all collaborative

Autonomous mobile robots (AMRs) differ from classic automated guided vehicles (AGVs) in two major aspects: First, they can be more flexible in their motion patterns, allowing, for example, deviation from pre-programmed paths to avoid obstacles or even free navigation. Second, they may carry additional tools such as a robot arm, which seems to be the case here.

General use of sensors: These additional abilities of an AMR need to be considered in the risk assessment. A more flexible navigation can mean that the AMR might approach persons unexpectedly, and, thus, it is more difficult for persons to avoid the AMR. This should be reflected with proper coverage by safety sensors, which could, for example, also include having protective areas on the side of the AMR.

If a manipulator is attached, the additional risks of a manipulator need to be taken into account. Usually, the manipulator should not move while the AMR is travelling. While in a fixed position, the manipulator can be active. Here it is important to ensure coverage with safety sensors for the area around the manipulator. The size of protective areas needs to follow ISO 13855, which means that also persons approaching the manipulator need to be detected in time. The new standard ANSI/RIA R15.08-1-2020 provides further guidance on integration of AMRs.

Question of collaboration: It should not be assumed that all robots are collaborative. Not all robots are equipped with the essential safety functions to allow collaborative use, such as safety-related speed monitoring and collision detection.

In addition, fitness for collaborative use always has to consider the application as a whole. The tool and its weight and geometry, such as points and sharp edges, have a large impact on maintaining allowed contact forces and pressures. In addition, allowable contact forces vary depending on the body parts that might be exposed to the robot. ISO 10218-2 and ISO TS 15066 provide further guidance here.

Presence sensing: The most common sensors for presence sensing are optoelectronic sensors such as light curtains or laser scanners. They have the advantage that they can detect an obstacle over larger distances without obstructing the workspace for workers or the AMR itself.

If a manipulator has low power, pressure-sensitive covers on the robot can also be used to detect contact and avoid harmful collisions. Safety switches can help to determine that a mobile platform has safely reached a goal position so that the manipulator may start operating. In general, only safety sensors with a sufficient performance level (PL), according to ISO 13849-1 may be used. Usually, a PL d is required.

A safe sensor that can reliably distinguish between robot, human and obstacle does unfortunately currently not exist. However, in the context of automatic loading and unloading gates with light curtains, approaches exist to mute sensors and allow entry as long as some pre-defined patterns, such as size of the object, are fulfilled.

Theo Jacobs / project leader and certified machinery safety expert / Fraunhofer IPA

Sensor safety fusion

To start, it may be necessary to distinguish that the traditional AGV, covered under the B56.5 safety standard, typically does not leave its intended path, making the safety discussion a bit more defined. AMRs, on the other hand, are designed to dynamically plan their path, making them more flexible. Unfortunately, the B56.5 was not designed to completely cover this flexibility, making it mostly unusable for the new generation of AMRs.

This challenge led to the development of a standard around dynamic mobile robots. Called the R15.08, this new standard for AMRs, or industrial mobile robots (IMRs), as they are called in the standard, has now been approved and released.

Following this guideline, as well as performing the standard risk assessments, will provide the structure required for AMRs to operate safely in plant and around people, even when dynamically planning the route to the next objective.

Concerning a “master sensor,” this, unfortunately, does not exist. As the environments in which these systems are deployed become more dynamic, so do the sensing requirements. Traditional 2D safety LiDARs and now being supported by both 3D cameras and LiDARs for detecting cantilevered or negative obstacles—think stairs.

2D cameras are utilized to classify people versus objects, allowing the robot to alert the operator that it is approaching and generating a better human/robot relationship. And ultrasonic sensors, as an example, are being utilized to detect clear objects, typically invisible to the other sensing modalities.

In fact, one of the biggest challenges for mobile robotics is the integration of all the sensing modalities required to bring both safety and efficiency to the use case.

While new developments are always happening, the challenge of providing the best perception for mobile robot applications will still be around sensor fusion.

Garrett Place / business development, robotics perception / ifm efector

Clear the loop

One way Hargrove has worked a similar problem was by use of area scanners and floor sensing loops. Area scanners can be programmed to view specific areas and configurations on the plant floor. Once an object/person enters that area, the safety system is triggered, resulting in equipment stoppage, messaging signal to the AGV and AMR. Another option that can be utilized are floor sensing loops. Just as a loop at a stop light detects stopped cars, the same technology has been successfully implemented in manufacturing facilities. Hargrove has used light curtains that prevent any operator from going into certain areas. However, if an AGV needs to pick up material and break the light curtain, the AGV will trigger the floor loop, which will essentially bypass or mute the light curtain, allowing for access without triggering the automatic shutdown of equipment typically associated with a break in the curtain.

As soon as the AGV is clear of the loop, the light curtain and associated function returns to normal. As standard AGVs typically have bump strips around the unit as a secondary fail safe in the event it bumps into anything or anyone.

Stephen Geyer / project manager / Hargrove Engineers + Constructors

Waypoint to waypoint

An AMR is a vehicle that uses onboard sensors and processors to autonomously move materials without the need for physical guides or markers. It learns its environment, remembers its location and dynamically plans its own path from one waypoint—a location or destination within the environment—to another.

Using technology such as sensors and simultaneous localization and mapping (SLAM), an AMR will determine the best route between waypoints. An AMR will automatically sense and avoid obstacles and blocked paths to find the best route to its next waypoint. An AMR will dynamically plan the shortest path based on current conditions and requirements, if the work changes from one day to the next, the AMR’s route will change with it.

AMR requires no alterations to your current facility and can autonomously navigate through manufacturing and warehouse spaces. It learns its environment, remembers its location and dynamically plans its own path from one destination to another. If its path is blocked, an AMR can reroute itself with no assistance.

The sensors an AMR uses to navigate ensure that it can operate safely in a dynamic environment alongside humans and material-handling equipment. And because an AMR is not a permanent structure in the facility, it can be moved and re-deployed with minimal cost as your business grows and changes over time. In fact, an AMR can work in one part of the facility in the morning and be deployed for a completely different task later in the day.

AMRs are collaborative and flexible to keep up with future opportunities that come to manufacturing and warehouse operations. They can avoid obstacles and unburden workers from repetitive or back-breaking work so these workers can focus on more valuable and fulfilling jobs. Flexibility, advanced navigation and ease of deployment make AMRs the perfect solution to get you started in automating your dynamic operations and empowering your valued workforce who are on the job.

Adding a new layer of safety to the existing two layers, by moving the eyes and ears of the AMR to the facility ceiling, and its navigation and management brain to an AI-based central control-tower system, can help provide additional assurance.

AMR safety is commonly divided into two safety zones. The first is within the immediate perimeter of the AMR, where bumper sensors or pushing an emergency-stop switch stop the vehicle.

The second safety zone is the 3-to-5-foot perimeter: sensors such as red, green and blue light (RGB) and light detection and ranging (LiDAR) identify a moving object that blocks the AMR’s path and bring the AMR to a stop. Passive safety systems are also included, such as warning lights or audible warnings/alarm signals.

The two-zone safety method, however, has its limitations. AMRs have tunnel vision; their eyes and ears are embedded in the robot, so their ability to map and understand their environment is fairly limited. Even if AMRs did have multi-vision, just like humans, in an industrial environment, it is simply not enough. Adding more safety measures such as 3D sensors and requiring workers to wear tracking devices such as RFID tags can help ensure additional safety is provided and workers have extra protection.

Daniel Weiss / senior product manager / Newark

No one master sensor

Making a robot autonomous and mobile does not mean that it is collaborative, per se. A collaborative robot (cobot) is a robot that can work alongside human workers on the production or assembly line because it has various safety features. The safety features built into the cobot are key.

The AMR also has safety features built into it, which allow it to navigate around a facility and interact with human traffic, as well as vehicular traffic including forklifts, AGVs and trucks. The two main technologies used in these devices are optical and ultrasonic in nature. This being said, there are different ways to accomplish these tasks, so there is no one master sensor solution.

The best source for you is to follow two specifications that deal specifically in these areas. ANSI/PMMI B155.1-2016 deals with the safety requirements for packaging and processing machinery. ANSI/RIA R15.08-1-2020 deals with industrial mobile robots—safety requirements—Part 1: requirements for the industrial mobile robot. By examining these two standards, you will have the information you need to help and design your necessary safety systems. It is an exciting time for expansion. Good luck.

Perry Hudson / key account manager, packaging / Pepperl+Fuchs, Inc.

About the Author

Anna Townshend

Managing Editor

Anna Townshend has been a writer and journalist for 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, until she joined Endeavor Business Media in June 2020. She is the managing editor of Control Design and Plant Services.

Leaders relevant to this article: