How to meet pharmaceutical manufacturing standards with automated inspection

Antares Vision Group makes modular automated inspection machines (AIMs), designed for in-line and off-line inspection for a wide range of pharmaceutical products. Industry standards and product demand are driving automation in that market. Darryl Peterson, business development manager at Antares Vision Group, discusses how pharmaceutical trends have influenced machine design and the adoption of automation and the advanced technologies that go into automated inspection machines, such as advanced machine vision and artificial intelligence (AI).

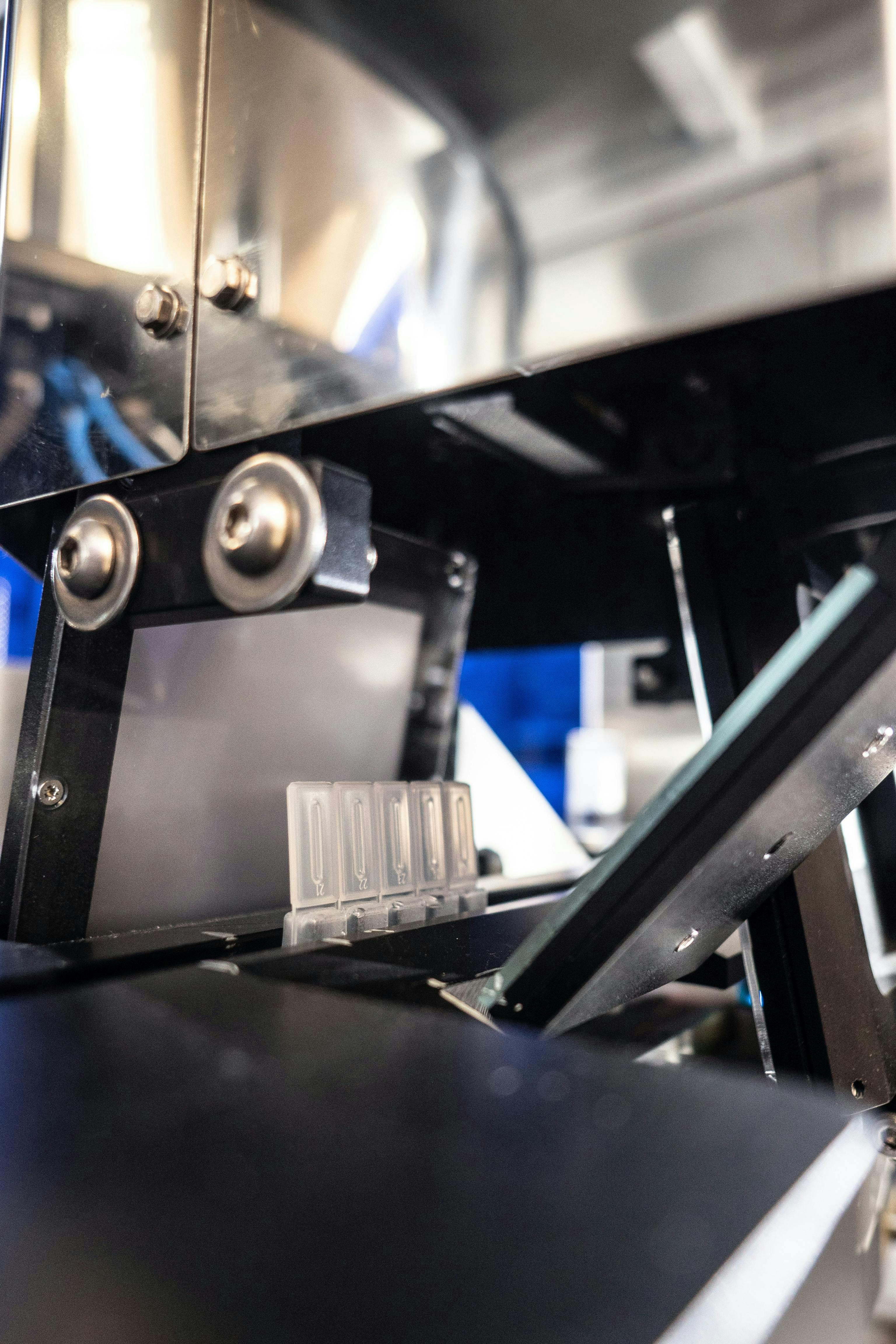

“In a space where flexibility is prioritized, the machines can handle various container types such as glass vials, tubular and molded, clear or amber glass, ampules, glass or plastic bottles and containers produced using thermoformed or blow-fill-seal techniques made from polymer plastics,” says Peterson. “Additionally, they are adept at inspecting prefilled syringes, cartridges and IV bags. This wide adaptability makes them applicable across multiple segments within the pharmaceutical industry, not limited to any specific niche.”

The machines can inspect various forms, including liquids, both clear and opaque, lyophilized products, powders, oily substances, suspensions and products with precipitates, as well as empty containers and cells.

Semi-automatic vs. automatic

Antares Vision Group classifies machines for the pharmaceutical industry in two main categories: semi-automatic and automatic. Semi-automatic machines involve a human operator who decides whether to accept or reject each container. “Containers are fed through the machine on rollers within a cabinet or hood and presented to the operator at a controlled speed, typically around 25 containers per minute. The vials mechanically rotate at varying speeds depending on the contents—liquid or powder. Strategic placement of lighting and mirrors enables the operator to assess the quality of each vial,” Peterson says.

Operators can stop machines and manually remove defective vials or containers. “Effective, semi-automatic machines operate slower than their automatic counterparts and are limited by the operator's speed, visual acuity and overall efficiency,” Peterson says.

Fully automatic machines are equipped with advanced cameras, lighting and the needed software to autonomously detect particles and cosmetic defects without human interaction. “Operators set up the machine programs for specific batches and oversee the operation to ensure smooth processing. However, all accept/reject decisions are made by sophisticated software algorithms. These algorithms analyze visual images using specific tools to identify particle and cosmetic defects,” Peterson says.

Automated machines are faster and more accurate than humans. They can handle batches in hours compared to days for semi-automatic inspection, Peterson says. “Given their remarkable speed, accuracy and capacity for large batch sizes and high-value products, AIMs are the preferred choice for continuous operation under stringent quality standards,” he adds (Figure 1).

Automation meets regulatory challenges

The pharmaceutical industries face challenges to meet numerous regulatory compliance standards, ensuring drug efficacy, robust quality processes and high standards of sterility and purity. “AIM systems address these challenges by validating their ability to detect particles of varying sizes and origins during sterile fill-finish operations,” Peterson says.

AIMs also help manufacturers distinguish between intrinsic particles, originating from the equipment, containers or contact parts, and extrinsic particles entering from external environments with special lightening and imaging techniques to capture and confirm particles. “This is verified by testing the machines with challenge containers that must consistently detect defects with 100% accuracy,” Peterson says.

Inspection also includes cosmetic aspects, any physical container defects like cracks, compromised seals or missing stoppers. AIMs also accurately assesses product fill levels to prevent dosage errors.

The advanced machine vision technologies used in AIMs include rapid vision processors, digital GigE cameras and programmable LED lighting. “These technologies enable the machines to capture and process images at speeds 20 times faster than human operators,” Peterson says. “Vision processors are incredibly efficient in comparing individual pixels to detect movements within a liquid vortex and discerning between bubbles and particles based on morphology, trajectory, reflectiveness and location.”

With dozens of images per second, the system can fine-tune lighting angles and intensity and switch between different types of lighting, such as near-infrared (NIR) lighting, which can penetrate dark amber glass. The software will compare against known standards and disregard irrelevant features, such as moving meniscus, container graduations or rising bubbles.

Proven technologies for leak detection, such as vacuum or pressure decay leak detection and high-voltage leak detection for liquids or syringes, are integrated into the AIM. This saves space, replacing separate machinery for leak detection.

“Additionally, head space gas analysis (HSGA) can be used within the inspection turret to assess the presence of gases like oxygen, water vapor or CO2, indicating the integrity of the container closure. For example, detecting oxygen inside a vacuum-sealed and nitrogen-backfilled lyophilized vial suggests a leak, prompting the machine to reject the container. These integrated solutions save manufacturers significant expenses and valuable production line real estate,” Peterson says.

AI inspection

Artificial intelligence in AIM enhances two critical areas: reducing false rejects and enabling predictive maintenance. “AI analyzes vast amounts of image data from the inspection process,” explains Peterson. “This analysis helps identify patterns and anomalies, allowing AI algorithms—referred to as the backbone—to pinpoint causes of false rejects and suggest adjustments to the inspection software. These AI-driven recommendations are then tested and, once validated, integrated into the machine's operating system to enhance accuracy and reduce wastage.”

Artificial intelligence also monitors data from sensors on critical components like gearboxes, vacuum pumps and torque motors to predict wear and tear and schedule maintenance. The AI models leverage accumulated data across various machines and customers. “This shared learning approach allows AI models to improve continually, benefiting from a broader data pool that enhances their predictive accuracy and reliability,” says Peterson. “Integrating customer-wide machine data into AI models represents a significant stride toward more intelligent, efficient manufacturing processes.”

Strict regulations guide the inspection process for pharmaceuticals. The design and operation of machine must meet FDA regulations around its current good manufacturing practice (CGMP) regulations to prove drug functionality and sterility and cleanliness practices. Software programs must comply with an FDA-regulated audit trail, and machine documentation for all testing of functions, alarm and product performance is required, Peterson says.

“The efficiency of a manual or automatic inspection system to inspect liquid products for particles is evaluated by means of the Knapp-Kushner test procedure, or Knapp Test for short,” says Peterson. “This method, accepted by the European Pharmacopeia and by the American FDA, is officially utilized as standard by the worldwide pharmaceutical industry. Using a mathematic and statistical base, it is based on a comparison between the efficiency of an existing inspection system, such as manual inspection, and one utilizing any other method, such as an automated inspection machine. The core of the test is the repetitive inspection of the same lot of products, prepared with known defect types and sizes in particle identification, to understand the probability of finding particles. All companies typically begin the inspection program using manual operators to set a baseline for performance of visual inspections. An automated machine must, at minimum, be able to achieve the same results.”